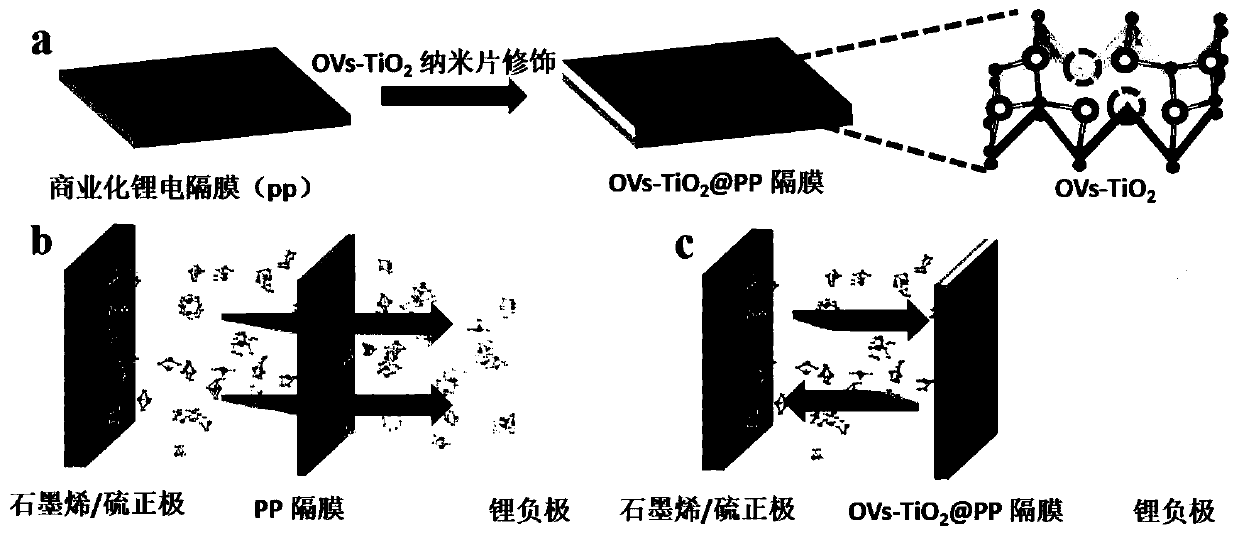

Oxygen-deficient titanium dioxide nanosheet modified lithium ion battery diaphragm and preparation method and application thereof

A lithium-ion battery and titanium dioxide technology, which is applied in the field of preparation of oxygen-deficient titanium dioxide nanosheet modified layers, can solve problems such as hindering lithium ion migration, reducing battery reaction kinetics, etc., achieving excellent cycle stability and high capacity, and improving conductivity. and catalytic ability, improving the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

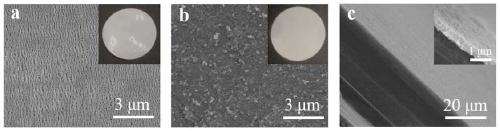

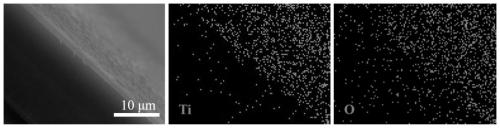

[0036] Oxygen-deficient titania nanosheets with a thickness of 500 nm modified polypropylene separator (OVs-TiO 2 @PP diaphragm) preparation, it includes the following steps:

[0037] 1) 30mg TiO 2 After the nanosheets are fully ground, in the tube furnace, under the flowing hydrogen atmosphere, the temperature is raised to 200 °C at 2 °C min, and kept at the target temperature for 2 hours, and then the tube furnace is naturally cooled;

[0038] 2) On the basis of step 1), obtain OVs-TiO 2 ;

[0039] 3) On the basis of step 2), 10mg OVs-TiO 2 Nanosheets were added to 50mL of absolute ethanol, ultrasonicated for 2 hours and then allowed to stand for 6 hours;

[0040] 4) On the basis of step 3), take 30mL of the supernatant, and take 5mL of the supernatant to dry and determine the OVs-TiO 2 Concentration of nanosheets (0.1-0.2mg mL-1);

[0041] 5) On the basis of step 4), take 15mL of the supernatant in the remaining solution by vacuum filtration, and load OVs-TiO on the P...

Embodiment 2

[0050] Oxygen-deficient titania nanosheets with a thickness of 200 nm modified lithium battery polypropylene separator (OVs-TiO 2 @PP diaphragm) preparation, it includes the following steps:

[0051] 1) 30mg TiO 2 After the nanosheets are fully ground, in the tube furnace, under the flowing hydrogen atmosphere, the temperature is raised to 200 °C at 2 °C min, and kept at the target temperature for 2 hours, and then the tube furnace is naturally cooled;

[0052] 2) On the basis of step 1), obtain OVs-TiO 2 ;

[0053] 3) On the basis of step 2), 10mg OVs-TiO 2 Nanosheets were added to 50mL of absolute ethanol, ultrasonicated for 2 hours and then allowed to stand for 6 hours;

[0054] 4) On the basis of step 3), take 30mL of the supernatant, and take 5mL of the supernatant to dry and determine the OVs-TiO 2 Concentration of nanosheets (0.1-0.2mg mL-1);

[0055] 5) On the basis of step 4), take 8 mL of the supernatant from the remaining solution through vacuum filtration, an...

Embodiment 3

[0060] Oxygen-deficient titania nanosheets with a thickness of 800 nm modified lithium battery polypropylene separator (OVs-TiO 2 @PP diaphragm) preparation, it includes the following steps:

[0061] 1) 30mg TiO 2 After the nanosheets are fully ground, in the tube furnace, under the flowing hydrogen atmosphere, the temperature is raised to 200 °C at 2 °C min, and kept at the target temperature for 2 hours, and then the tube furnace is naturally cooled;

[0062] 2) On the basis of step 1), obtain OVs-TiO 2 ;

[0063] 3) On the basis of step 2), 10mg OVs-TiO 2 Nanosheets were added to 50mL of absolute ethanol, ultrasonicated for 2 hours and then allowed to stand for 6 hours;

[0064] 4) On the basis of step 3), take 30mL of the supernatant, and take 5mL of the supernatant to dry and determine the OVs-TiO 2 Concentration of nanosheets (0.1-0.2mg mL-1);

[0065] 5) On the basis of step 4), the remaining 25mL supernatant was vacuum filtered, and OVs-TiO was loaded on the PP m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length and width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com