A method for forming a flat and ultra-thin power transformer magnetic core

A technology of power transformers and molding methods, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., to achieve the effects of reduced deformation, high superposition characteristics, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

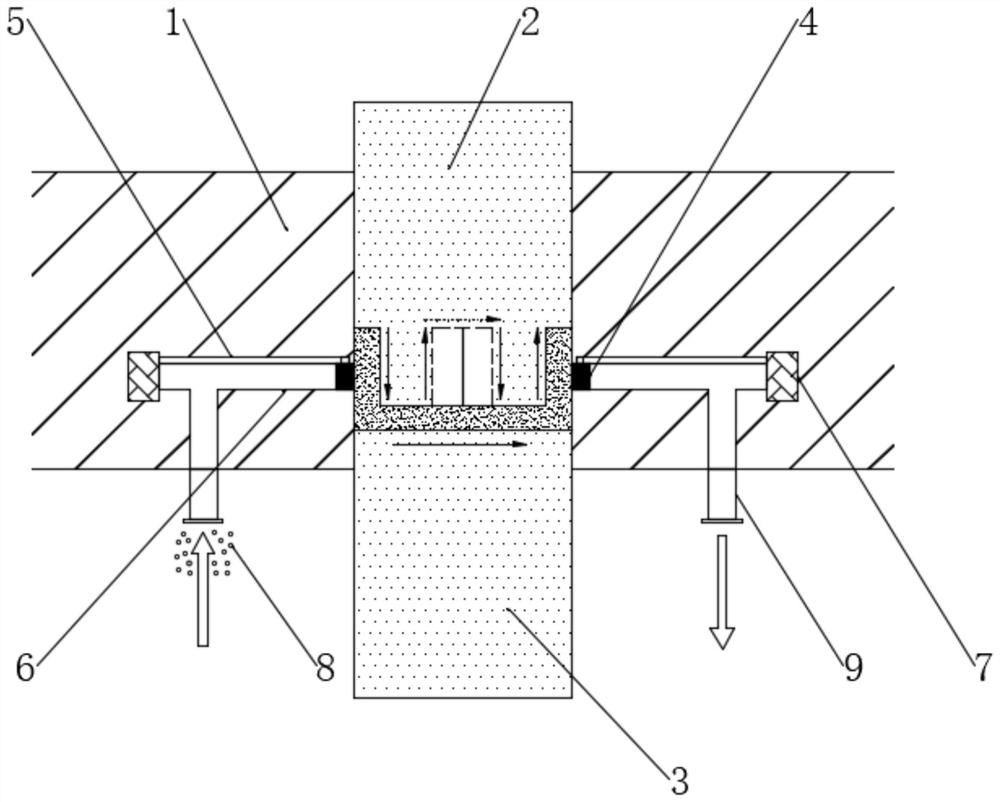

[0047] see Figure 1-2 , a method for forming a flat ultra-thin power transformer magnetic core, comprising the following steps:

[0048] S1. Batching: select suitable raw materials for batching and weighing, and obtain raw material powder after mixing;

[0049] S2. Initial pressing: the raw material powder is preliminarily pressed and formed through a mold to obtain a green body;

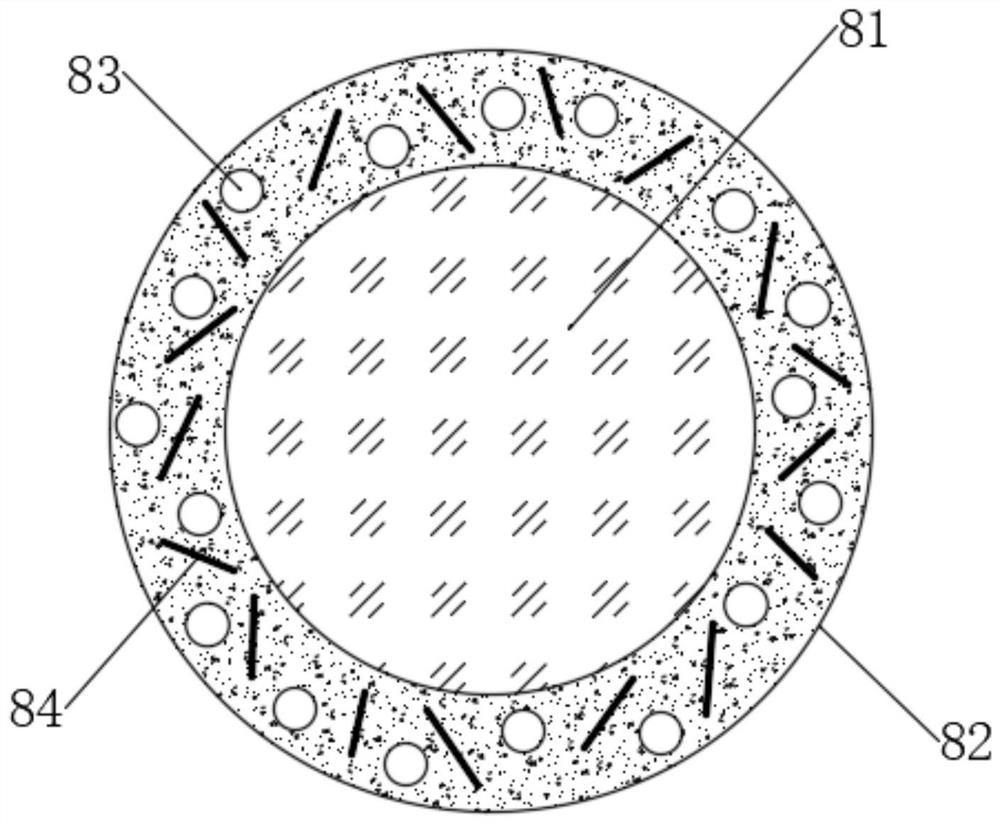

[0050] S3. Gap measurement: Introduce high-pressure gas into the mold, and the high-pressure gas is mixed with repair particles, the repair particles are used to fill the surface cracks on the green body, and the excess gas and repair particles 8 are recovered from the other end of the mold;

[0051] S4. Final pressure: apply a simple pressure to the green body to force the repair particles to disintegrate and start to repair the cracks on the green body to obtain a shaped green body;

[0052] S5. Sintering: placing the shaped green body in a sintering furnace for sintering treatment to obtain a ...

Embodiment 2

[0065] The molar percentages of each component in the raw material in step S1 are 51mol% Fe2O3, 25mol% MnO and the remaining ZnO, through the reasonable selection and proportioning of the components, the self-superposition characteristics of the manganese-zinc ferrite core are better than before It is higher and more stable, and also meets the requirements of high core inductance. It is suitable for the needs of high-power power transformers, provides conditions for the miniaturization and high efficiency of power transformers, and is conducive to reducing industrial processing costs and large-scale production. .

[0066] The particle size of the raw material is 80-120 mesh, the loose specific gravity is 1.38g / cm3, the particle diameter of the powder is consistent, and the forming is conducive to the mutual meshing of the pores between the powders. The increase of the density and strength of the green body is controlled from the point of view of the powder. In the process of c...

Embodiment 3

[0071] The molar percentages of each component in the raw material in step S1 are 52mol% Fe2O3, 28mol% MnO and the remaining ZnO, through the reasonable selection and proportioning of the components, the self-superposition characteristics of the manganese-zinc ferrite core are better than before It is higher and more stable, and also meets the requirements of high core inductance. It is suitable for the needs of high-power power transformers, provides conditions for the miniaturization and high efficiency of power transformers, and is conducive to reducing industrial processing costs and large-scale production. .

[0072] The particle size of the raw material is 80-120 mesh, the loose specific gravity is 1.40g / cm3, the particle diameter of the powder is consistent, and the forming is conducive to the mutual meshing of the pores between the powders. The increase of the density and strength of the green body is controlled from the point of view of the powder. In the process of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com