Carbon tank type calciner temperature control system based on multi-fire channel monitoring and realization method thereof

A tank-type calciner and temperature control system technology, which is applied in the direction of furnace control device, furnace monitoring device, furnace, etc., can solve the problem of poor quality of carbon materials, no longer suitable for automatic production, inability to calciner temperature, furnace pressure and air intake Control and other issues to achieve the effect of improving quality and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

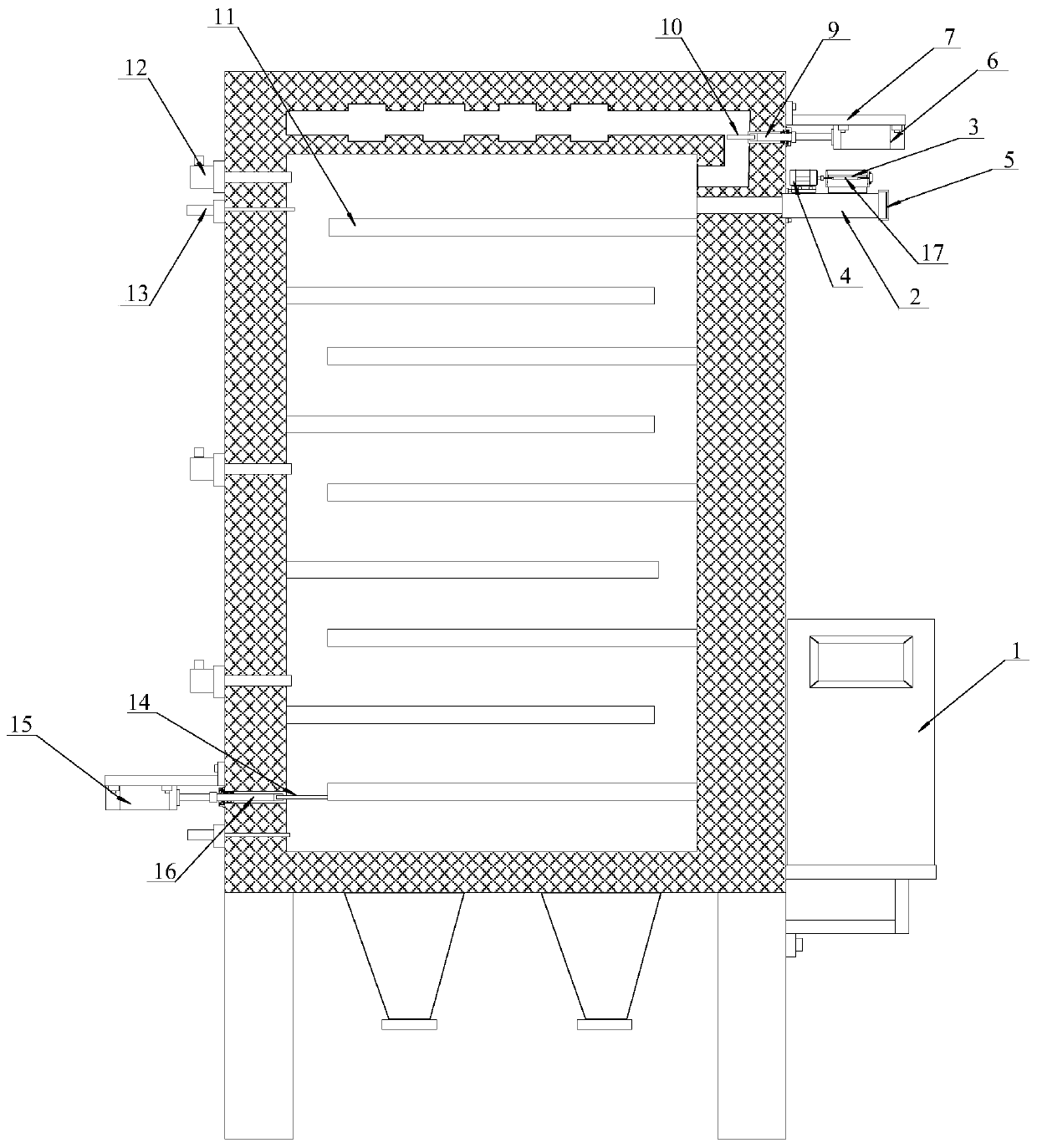

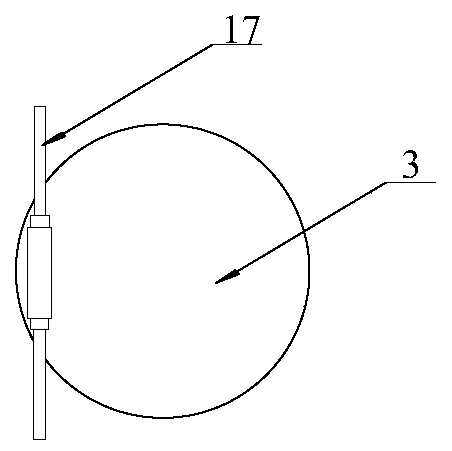

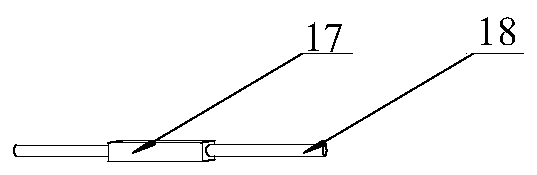

[0036] Such as Figure 1~6 As shown, the carbon tank type calciner temperature control system based on multi-fire channel monitoring includes a furnace body, a multi-layer fire channel arranged in the furnace body, and a temperature control system arranged on the furnace body; the furnace body in this embodiment A traditional furnace body with volatile matter channels, pressure regulating holes, temperature regulating holes and tuyere is adopted. The multi-layer fire path is a traditional ten-layer fire path, and multiple fire path plates 11 are arranged in the multi-layer fire path. Both the furnace body and the multi-layer fire channel are prior art, and their structures will not be repeated here. The inventive point of the present invention lies in the structure of the temperature control system and its realization method, and the following description focuses on the structure and its realization method.

[0037] The temperature control system includes a controller 1 , a p...

Embodiment 2

[0044] Such as Figure 7 As shown, the present embodiment is the implementation method of the temperature control system of the carbon tank type calciner based on multi-fire channel monitoring of embodiment 1, which includes the following steps:

[0045] Step 1: Set the temperature reference value of the multi-layer fire path and the negative pressure reference value of the multi-layer fire path.

[0046] Specifically, when setting the temperature reference value of the multi-layer fire path and the negative pressure reference value of the multi-layer fire path, it is entered through the controller 1, and the temperature reference value of the multi-layer fire path and the multi-layer fire path The negative pressure reference value is set according to the control temperature value set according to the production process.

[0047] Step 2: Collect the pressure value information on the first-layer flue path and the tail-layer flue path to obtain the actual negative pressure valu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com