Three-layer coupling power generation method by using LNG cold energy and temperature difference double loops and fuel gas

A dual-circuit, temperature-difference technology, applied in combined engines, gas treatment applications, container discharge methods, etc., can solve the problems of single-circuit current, small power generation efficiency, cold energy waste, etc., to increase the variety of output products and reduce costs. , the effect of increasing power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

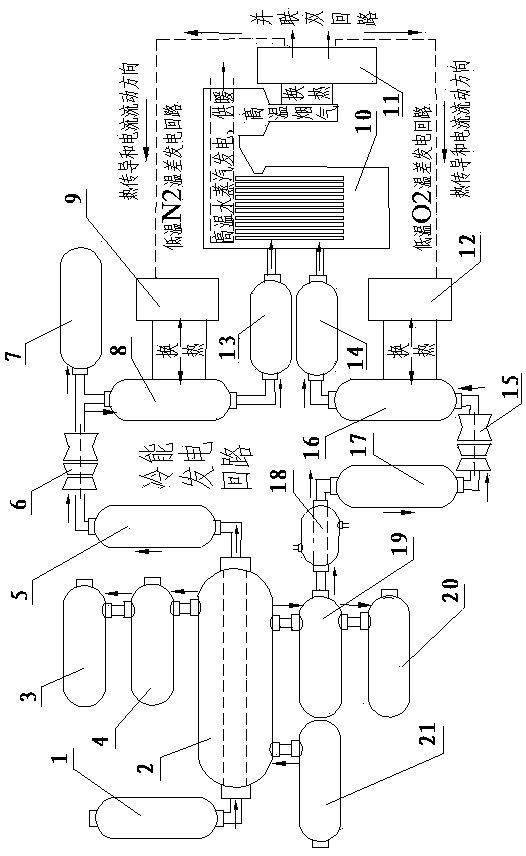

[0015] A method of generating electricity by applying LNG cold energy, temperature difference double circuits and gas three-layer coupling, the method comprises: LNG cryogenic liquid tank 1, the LNG cryogenic liquid tank is connected with cryogenic liquid CH4 pipeline 2, The cryogenic liquid CH4 pipeline is connected with the high-pressure and low-temperature CH4 buffer tank 5, and the high-pressure and low-temperature CH4 buffer tank is respectively connected with the atmospheric pressure and low-temperature CH4 buffer tank 8 and the compressed CNG tank 7 through the low-temperature methane steam turbine 6, and the normal-pressure and low-temperature CH4 buffer tank 7 is connected respectively. The low-pressure and low-temperature CH4 buffer tanks are respectively connected with the low-temperature negative electrode thermoelectric power generation sheet A9 and the normal-pressure high-temperature CH4 buffer tank 13, and the normal-pressure high-temperature CH4 buffer tanks and...

Embodiment 2

[0017] According to the application of LNG cold energy, temperature difference dual-circuit and gas three-layer coupled power generation method described in Example 1, this method is: firstly, the LNG cold energy double-circuit power generation mode is respectively: cryogenic natural gas LNG and normal temperature and low pressure, the pressure of which is 5MPa After heat exchange with the air, liquid oxygen is produced respectively, with a liquefaction temperature of -118°C, and low-temperature nitrogen, with a liquefaction temperature of -196°C. At the same time, the secondary product liquid oxygen is exchanged with seawater to form low-temperature natural gas and low-temperature oxygen. Direct blowing of natural gas and oxygen turbines to form a double circuit for power generation, and simultaneously produce low-temperature nitrogen, liquid oxygen, and low-temperature natural gas CNG as additional product output. According to calculations, under ideal conditions, 1Kg of LNG c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com