Double-row pile supporting structure

A technology of supporting structure and double-row piles, which can be used in infrastructure engineering, coastline protection, excavation, etc., can solve the problems of weak bending resistance and limited effect of single-row piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

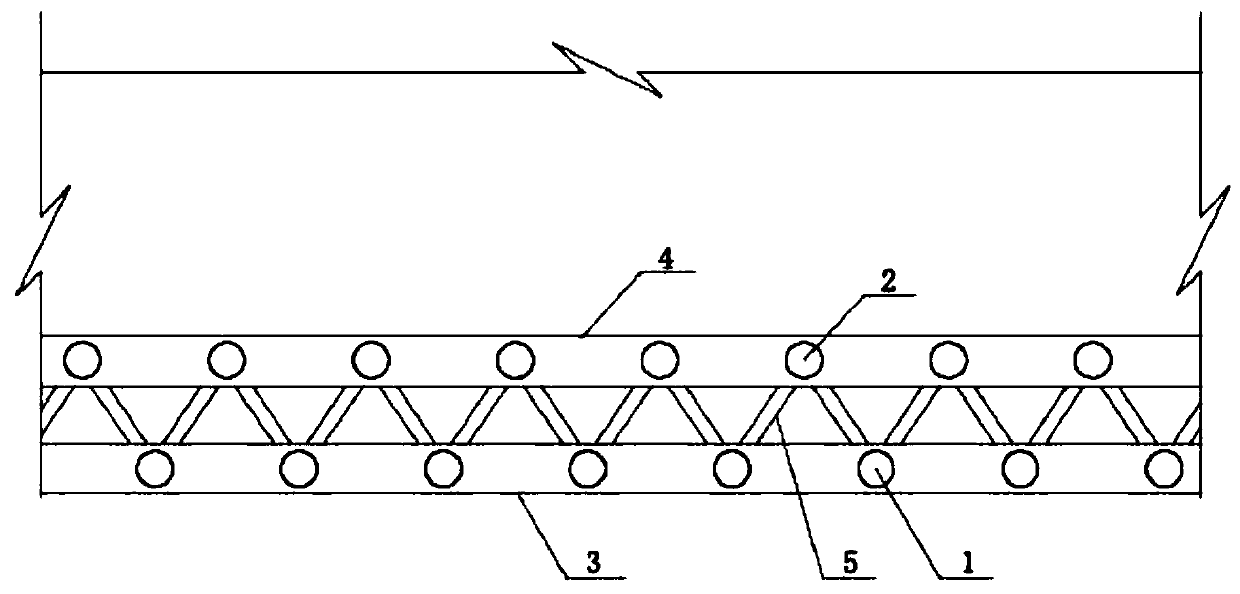

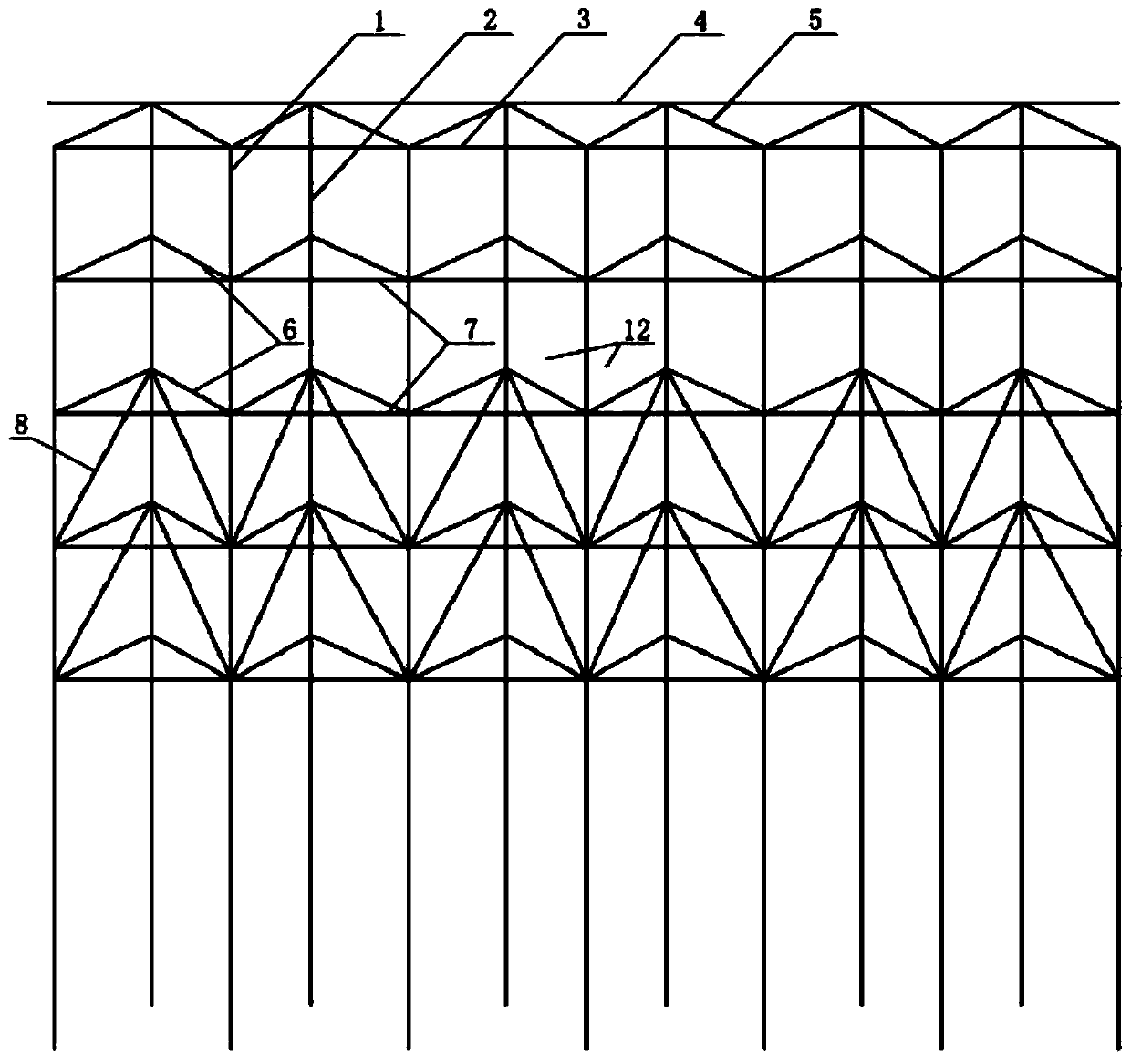

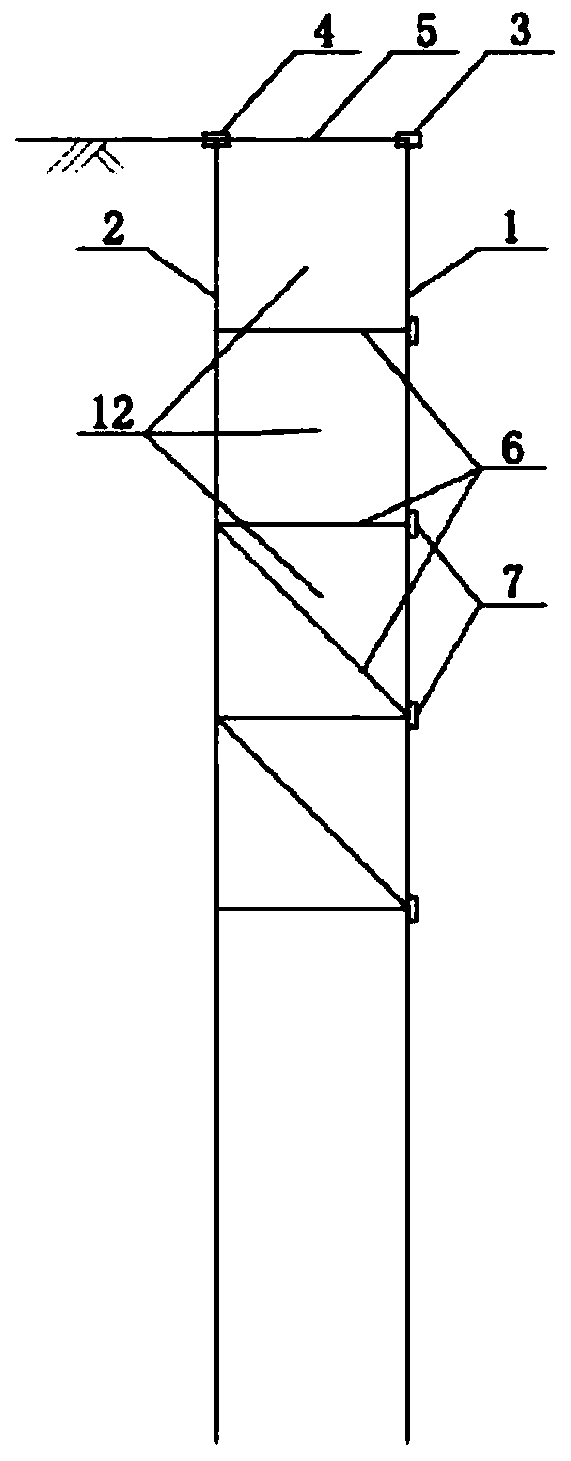

[0036] A double-row pile support structure, which is used in the slope support and is a permanent structure. The pile diameter of the front row is 800mm, and the pile diameter of the back row is 800mm. The reinforced concrete pouring pile is constructed by mechanical hole forming , arranged in double rows of equilateral triangles, with a spacing of 2m. Several groups of steel bars are reserved for the front row of pile webs. Each group has 10 steel bars with a diameter of 22mm, which are used to connect the front row of web bars. Each group has 10 pieces with a diameter of 22mm. The diameter of the steel bars reserved for the front row of pile reinforcement mesh is 10mm and the vertical spacing is 150mm. There are several sets of steel bars reserved for the back row of pile web bars in the rear row of piles. The steel bars are 10 for each group. The root diameter is 22mm, and the diameter of the steel bars reserved for the rear row of reinforcement mesh is 10mm and the vertical...

specific Embodiment 2

[0039] A double-row pile support structure is different from Embodiment 1 in that the use scenario is temporary foundation pit support. The front row of piles and the rear row of piles are made of steel pipe piles, the diameter of which is 500mm, and the vibro-pile method is adopted. The double rows of equilateral triangles are arranged with a distance of 1.5m. Bolt holes are reserved for the pile body of the front row, and bolt holes are reserved for the pile body of the rear row. The top of the front row of piles is equipped with double 300mm I-steel front crown beams and front connecting plates, and the rear pile top is equipped with double 300mm I-steel rear crown beams and rear connecting plates. Connecting plates and bolts connect the front row of piles and the rear row of piles.

[0040] Then carry out excavation in layers and grades of the foundation pit, and every layer of high 500mm excavation installs a V-shaped soil retaining plate, which is equivalent to the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com