Fluoride-free waterproof oil-proof food-grade coating and preparation method thereof

A fluorine-free waterproof, food-grade technology, used in paper coatings, coatings, adding water repellents, etc., can solve the problems of difficult recycling of coated paper, limited application range, strong bioaccumulation, etc., to improve efficiency and gloss. Good, good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

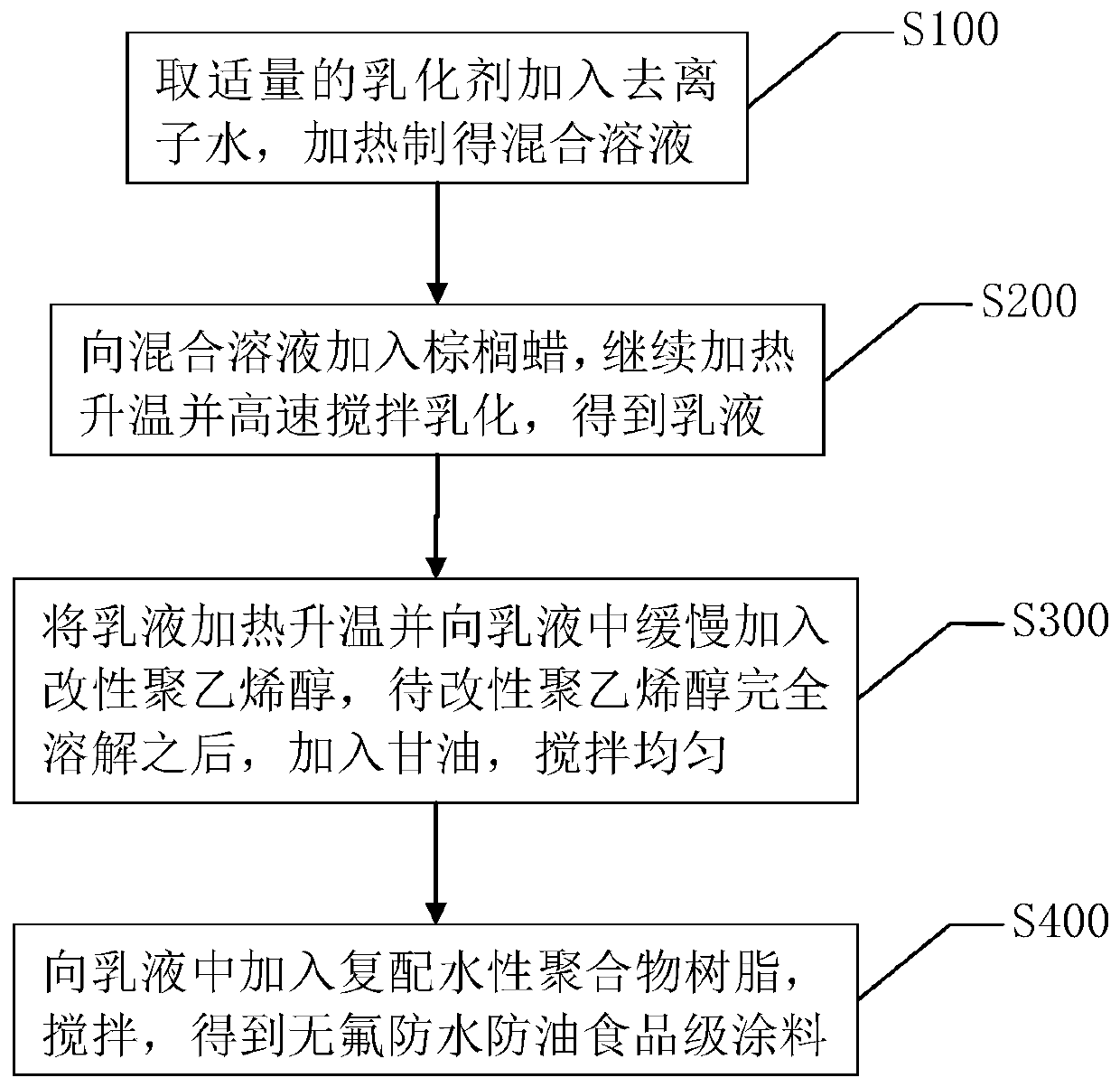

[0033] Such as figure 1 Shown, the preparation method of fluorine-free waterproof and oil-proof food-grade coating of the present invention, comprises the following steps:

[0034] S100. Take an appropriate amount of emulsifier and add it to deionized water, and heat to prepare a mixed solution; where the temperature is raised to 90°C.

[0035] S200. Add palm wax to the mixed solution, continue to heat up and emulsify with high-speed stirring to obtain an emulsion; heat up to 100°C-120°C (the optimal solution is to heat the emulsion to boiling), and the stirring speed is 1500r / min-2000r / min min, the emulsification time is 30min-45min.

[0036] S300. Heating the emulsion and slowly adding modified polyvinyl alcohol into the emulsion. After the modified polyvinyl alcohol is completely dissolved, add glycerin and stir evenly; the stirring time is 1 h.

[0037] S400. Add the compounded water-based polymer resin to the emulsion and stir to obtain a fluorine-free waterproof and oi...

Embodiment 1

[0041] a. Take 1.5g of emulsifier and add 64.7g of deionized water, and heat up to 90°C to obtain a mixed solution;

[0042] b. Add 5.0 g of palm wax to the mixed solution obtained in step a, continue heating to 105° C., and emulsify at a high speed of 1500 r / min for 30 min;

[0043] c. Warm up the emulsified emulsion in step b to 95°C, then slowly add 3.0 g of modified polyvinyl alcohol to the emulsion, after it is completely dissolved, add 0.8 g of glycerin, and stir for 1 hour until the reaction is complete;

[0044] d. After the emulsion in step c is cooled to room temperature, add 25 g of water-based polyurethane resin and polyacrylate composite resin to the emulsion, and stir at room temperature for 15 minutes to obtain a fluorine-free waterproof and oil-proof food-grade coating.

[0045] The fluorine-free waterproof and oil-proof food-grade paint prepared in Example 1 is coated on food-grade white cardboard, and the coating amount is 6g / m 2 , bake at 60°C for 5min. Th...

Embodiment 2

[0047] a. Take 2.0g of emulsifier and add 59g of deionized water, and heat up to 90°C to obtain a mixed solution;

[0048] b. Add 7.0 g of palm wax to the mixed solution obtained in step a, continue heating to 105° C., and emulsify at a high speed of 1500 r / min for 30 min;

[0049] c. Heat up the emulsified emulsion in step b to 95°C, then slowly add 3.55g of modified polyvinyl alcohol into the emulsion, after it is completely dissolved, add 0.95g of glycerin, and stir for 1 hour until the reaction is complete;

[0050]d. After the emulsion in step c is cooled to room temperature, add 27.5 g of water-based polyurethane resin and polyacrylate composite resin to the emulsion, and stir at room temperature for 15 minutes to obtain a fluorine-free waterproof and oil-proof food-grade coating.

[0051] The fluorine-free waterproof and oil-proof food-grade paint prepared in Example 2 is coated on food-grade white cardboard, and the coating amount is 8g / m 2 , bake at 60°C for 5min. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com