Heterogeneous catalytic gasification reactor for coal

A technology of gasification reactor and heterogeneous catalysis, which is applied in the direction of gasification process, fuel pre-distillation, petroleum industry, etc., can solve the problems of inefficient and clean utilization, and achieve the effect of ensuring the original state and in situ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

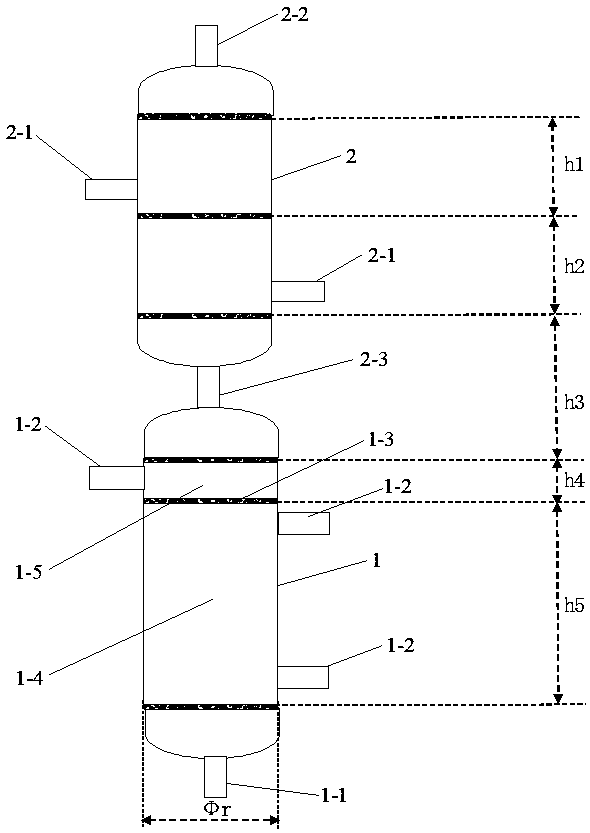

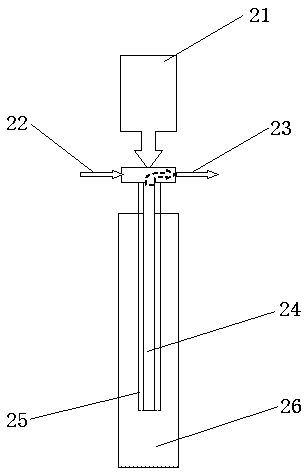

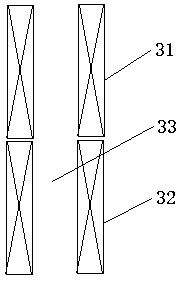

[0025] see figure 1 , in this embodiment, a coal heterogeneous catalytic gasification reactor, including a feed system, a gas system, a heating system, a solid-gas reactor 1 and a gas-gas reactor 2, the bottom of the solid-gas reactor 1 is connected with a main gas Intake pipe 1-1, the top of solid-gas reactor 1 is connected with the bottom of gas-gas reactor 2 through connecting pipe 2-3, and the top of gas-gas reactor 2 is connected with outlet pipe 2-2; solid-gas reactor 1 and gas The inside of the gas reactor 2 is equipped with partitions 1-3, and the partitions 1-3 divide the interior of the solid-gas reactor 1 and the gas-gas reactor 2 into several compartments from bottom to top. Several feeding pipes 1-2 are connected to the side wall, and several secondary gas inlet pipes 2-1 are connected to the side wall of the gas-gas reactor 2.

[0026] The feeding pipes 1-2 communicate with different compartments in the solid-gas reactor 1 respectively, and the secondary gas inl...

Embodiment 2

[0034] Experimental objectives: the release of sulfur and nitrogen elements in the volatile matter of bituminous coal during fluidized bed pyrolysis;

[0035] Solid gas reactor 1:

[0036] Form: fluidized bed; bottom bed material: zirconium dioxide (zircon sand);

[0037] Dimensions: Inner diameter Φr = 40mm, height h5 = 180mm;

[0038] Reaction temperature: 900°C;

[0039] Upper compartment 1-5: h4=20mm, no filler;

[0040] Feed: 0.2mm bituminous coal, feed amount 10g, feed flow rate: 100mg / min;

[0041] Fluidizing gas: argon, flow rate 0.9L / min;

[0042] Injection gas blowing: argon, flow rate 0.1L / min;

[0043] Gas reactor 2:

[0044] Form: entrained bed; no bed material; size: inner diameter same as above, height h1+h2=200mm; reaction temperature: 900°C;

[0045] Intake air: oxygen; 0.6L / min;

[0046] Compartment: no padding;

[0047] Detection Systems:

[0048] Use the flue gas composition analyzer to detect the concentration of SOx and NOx at the outlet of gas-ga...

Embodiment 3

[0051] Experimental objectives: During fluidized bed pyrolysis, the release of sulfur and nitrogen elements from the interaction between bituminous coal volatiles and coal char;

[0052] Solid gas reactor 1:

[0053] Form: fluidized bed; bottom bed material: zirconium dioxide (zircon sand);

[0054] Dimensions: Inner diameter Φr = 40mm, height h5 = 180mm;

[0055] Reaction temperature: 900°C;

[0056] Upper compartment 1-5: h4=20mm, 0.2mm particle size bituminous coal 10g;

[0057] Feed material: bituminous coal, feed amount 10g, feed flow rate: 100mg / min;

[0058] Fluidizing gas: argon, flow rate 0.9L / min;

[0059] Injection gas blowing: argon, flow rate 0.1L / min;

[0060] Gas reactor 2:

[0061] Form: entrained bed; no bed material; size: inner diameter same as above, height h1+h2=200mm; reaction temperature: 900°C;

[0062] Intake air: oxygen; 0.6L / min;

[0063] Compartment: no padding;

[0064] Detection Systems:

[0065] Use the flue gas composition analyzer to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com