Formed coke and preparation method and application thereof

A technology for coke powder and briquette, which is applied in the field of moulded coke and its preparation, can solve the problems of poor thermal strength of moulded coke, low yield and low crushing strength, and achieves the effects of less internal cracks, low ash content and large lumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The first aspect of the present invention provides a method for preparing coke, comprising:

[0013] (1) The mixed coal obtained by mixing the raw materials is pressed to obtain briquettes; based on the total weight of the raw materials, the raw materials include: coke powder 15-25wt%, fat coal 60-70wt%, lean coal 5-15wt% %;

[0014] (2) Put the briquettes into a coke oven at room temperature, raise the temperature of the coke oven from room temperature to 1050-1200°C at a rate of 6-10°C / h, and conduct dry distillation at 1050-1200°C for 350-400h to obtain Type coke.

[0015] Coke powder with low ash content and strong anti-shrinkage ability, fat coal with high ash content and high caking performance and lean coal with low caking performance are blended according to a specific ratio. The reasonable proportion of coal, rubber powder and lean coal can make full use of the characteristics of different coal types, and it can be reasonably matched with the coking time and ...

Embodiment 1

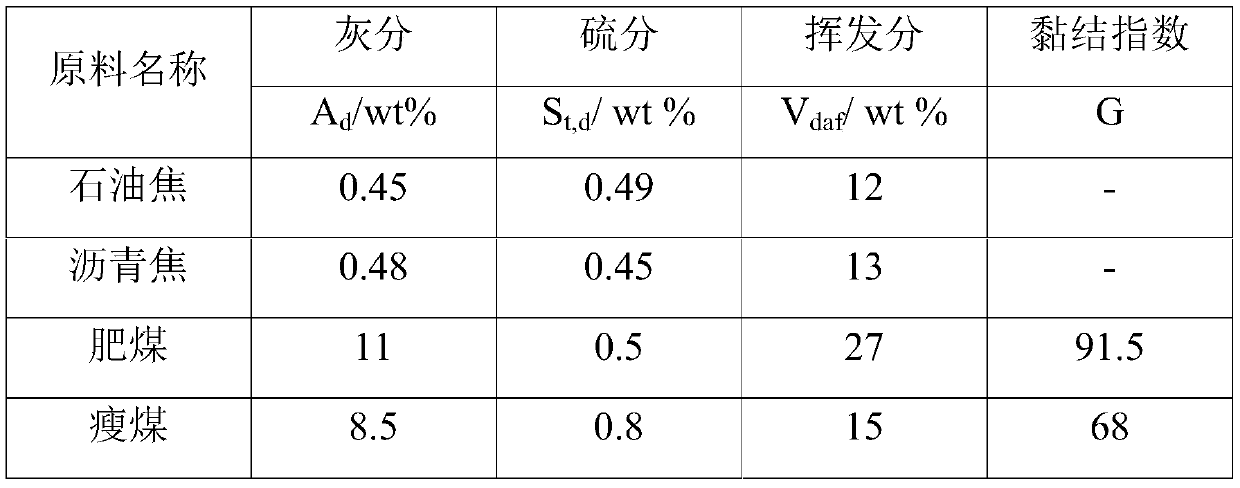

[0030] The property parameters of the raw materials for preparing molded coke in the present embodiment are as shown in Table 1, the ratio of the caking index of the fat coal to the caking index of the lean coal is 1.35:1, and the composition of the raw materials is as shown in Table 2; The preparation method of described coke is as follows:

[0031] (1) Petroleum coke is pre-crushed to obtain petroleum coke powder, based on the total weight of the petroleum coke powder, the average particle size of 95wt% of the coke powder is 3 ,

[0032] (2) Put the briquettes into the coke oven at room temperature, raise the temperature of the coke oven from room temperature to 1100°C at a rate of 8°C / h, and conduct dry distillation at 1100°C for 380 hours. The mold coke was rinsed with water until the mold coke was cooled to room temperature to obtain mold coke A1.

[0033] The performance parameters of the coke A1 obtained in this embodiment are shown in Table 6.

[0034] Table 1: The p...

Embodiment 2-5

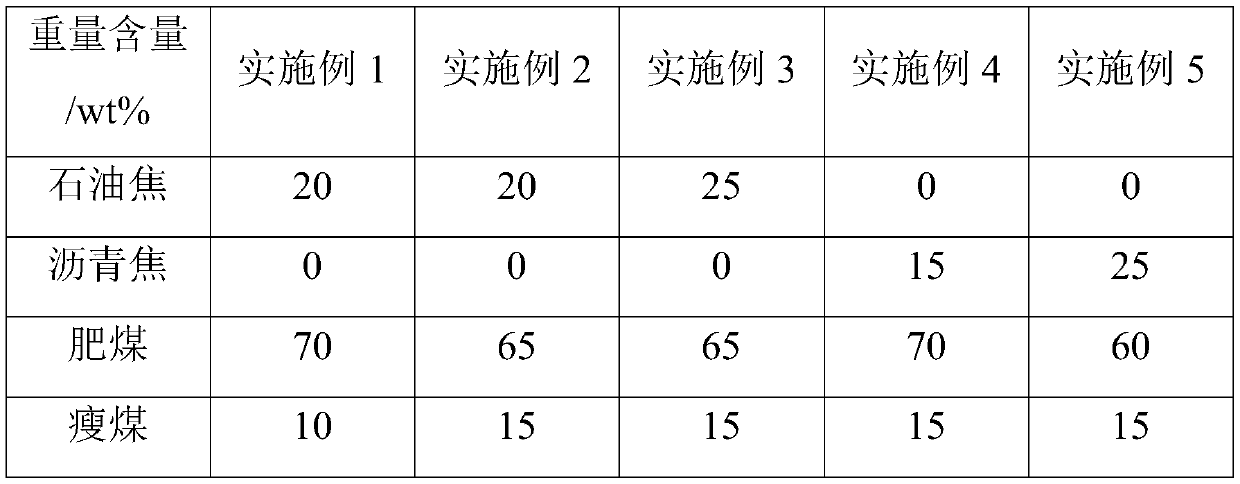

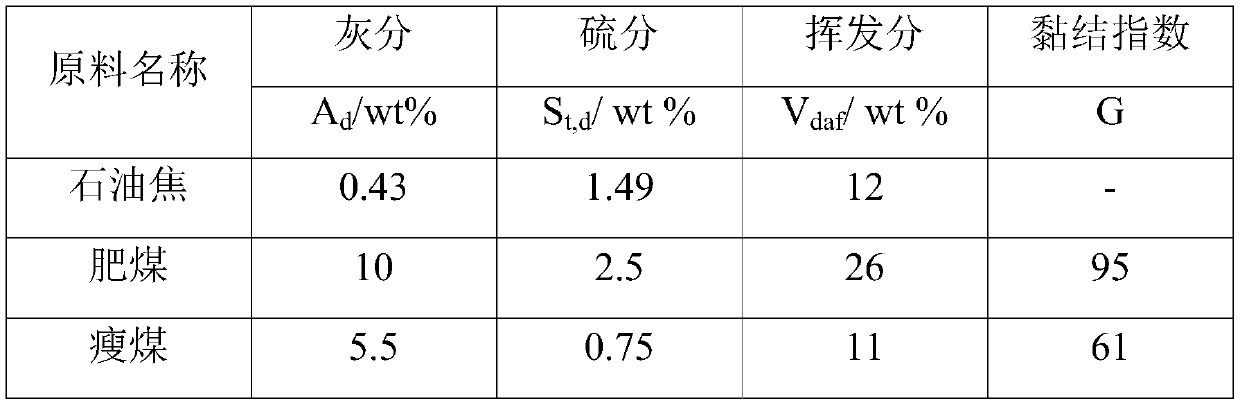

[0037] Table 1 shows the property parameters of the raw materials for preparing the form coke in Examples 2-5, and Table 2 shows the composition of the raw materials.

[0038] The preparation method of the molded coke is the same as in Example 1 to obtain molded cokes A2-A5.

[0039] The performance parameters of the cokes A2-A5 obtained in Examples 2-5 are shown in Table 6.

[0040] Table 2: The composition of raw material among the embodiment 1-5

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com