Soil stabilizer capable of improving drying shrinkage performance of compacted soil and preparation method thereof

A soil curing agent and shrinkage performance technology, applied in the field of building materials, can solve the problems of low early strength, slow strength development, affecting construction progress, etc., and achieve improved bond strength and surface strength, excellent drying shrinkage resistance, curing and The effect of hardening the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

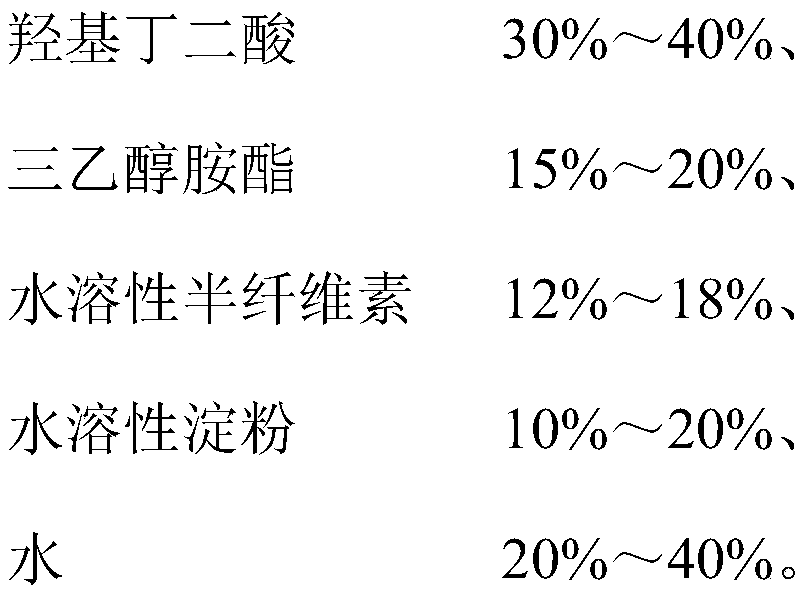

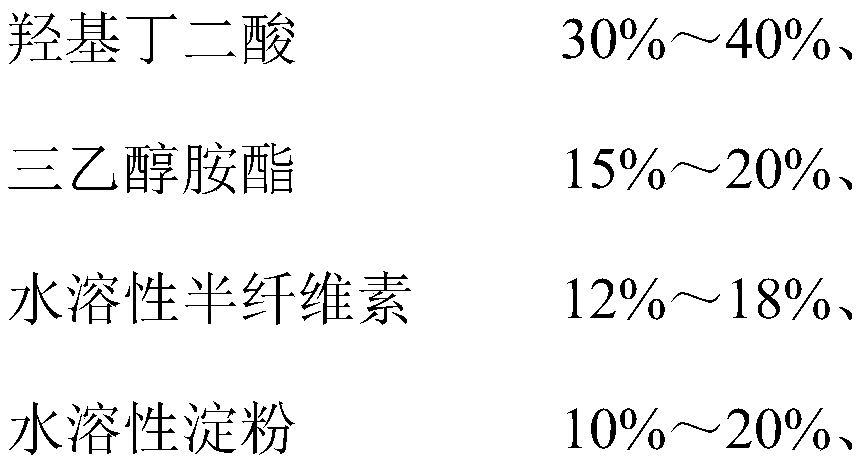

[0033] Formula (mass percentage): 30% of hydroxysuccinic acid, 15% of triethanolamine ester, 15% of water-soluble hemicellulose, 10% of water-soluble wheat starch, and 30% of water.

[0034] Preparation method: take 1 / 3 of water and stir hydroxysuccinic acid and triethanolamine ester to obtain mixture I; take the remaining water and stir water-soluble hemicellulose and water-soluble wheat starch to obtain mixture II; mix mixture I Mix well with mixture II and dry at 70°C to obtain.

Embodiment 2

[0036] Formula (mass percentage): 33% of hydroxysuccinic acid, 20% of triethanolamine ester, 12% of water-soluble hemicellulose, 15% of water-soluble wheat starch, and 20% of water.

[0037] Preparation method: take 1 / 3 of water and stir hydroxysuccinic acid and triethanolamine ester to obtain mixture I; take the remaining water and stir water-soluble hemicellulose and water-soluble wheat starch to obtain mixture II; mix mixture I Mix well with mixture II and dry at 60°C to obtain.

Embodiment 3

[0039] Formula (mass percentage): 30% of hydroxysuccinic acid, 15% of triethanolamine ester, 18% of water-soluble hemicellulose, 10% of water-soluble wheat starch, and 27% of water.

[0040] Preparation method: take 1 / 3 of water and stir hydroxysuccinic acid and triethanolamine ester to obtain mixture I; take the remaining water and stir water-soluble hemicellulose and water-soluble wheat starch to obtain mixture II; mix mixture I Mix well with mixture II and dry at 60°C to obtain.

[0041] Control group 1

[0042] Ordinary Portland cement 32.5 is used as curing agent.

[0043] Control group 2

[0044] Formula (number of parts by mass):

[0045]

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com