Rapid repair material for bridge expansion joints and preparation method thereof

A technology for repairing materials and expansion joints, applied in the field of construction engineering, can solve problems such as difficult to meet the fast and efficient repair performance of expansion joints, and achieve the effects of good buffering, integration, stability and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

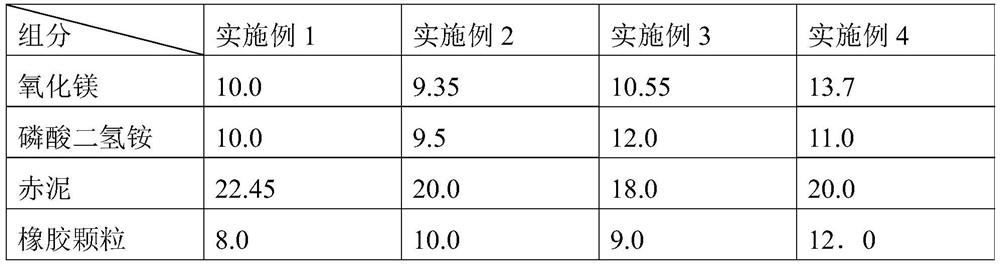

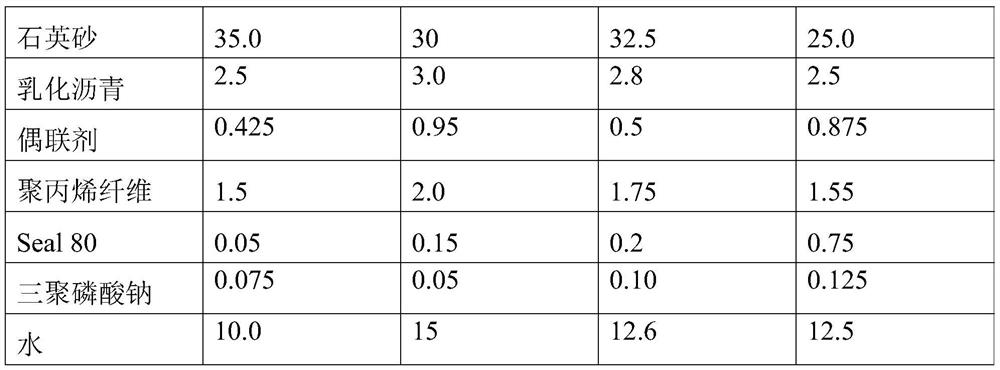

Embodiment 1~4

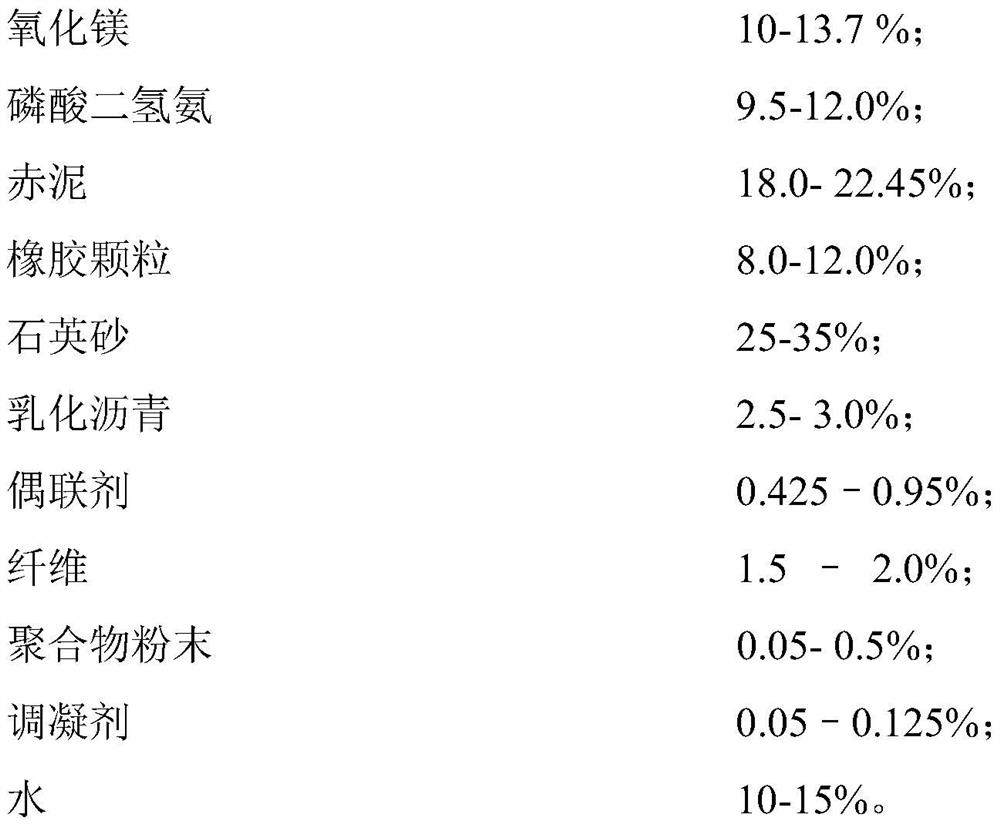

[0029] Bridge expansion joint rapid repair material, composed of magnesium oxide, ammonium dihydrogen phosphate, red mud, rubber particles, quartz sand, emulsified asphalt, coupling agent, fiber, polymer powder, coagulant and water in a certain proportion, with the following process The method is completed: first add the crushed rubber tire particles according to the proportion design requirements into the mixer and stir, add the weighed emulsified asphalt and coupling agent, and stir for 1min; then add the weighed magnesium oxide, ammonium dihydrogen phosphate, red mud , quartz sand, polymer powder and coagulation agent were added and stirred for 1min; water was added in portions, stirred into a fluid mixture, and fibers were added to continue stirring, and the stirring time was controlled within 5 minutes; the formed fluid concrete mixture It is poured into the expansion joint, vibrated and formed within 5 minutes, polished and plastered, and can be opened to traffic after 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com