Construction waste recycling method

A technology of construction waste and recycled aggregates, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of large pieces of garbage falling into it, and achieve anti-oxidation and corrosion, firm structure, and good cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

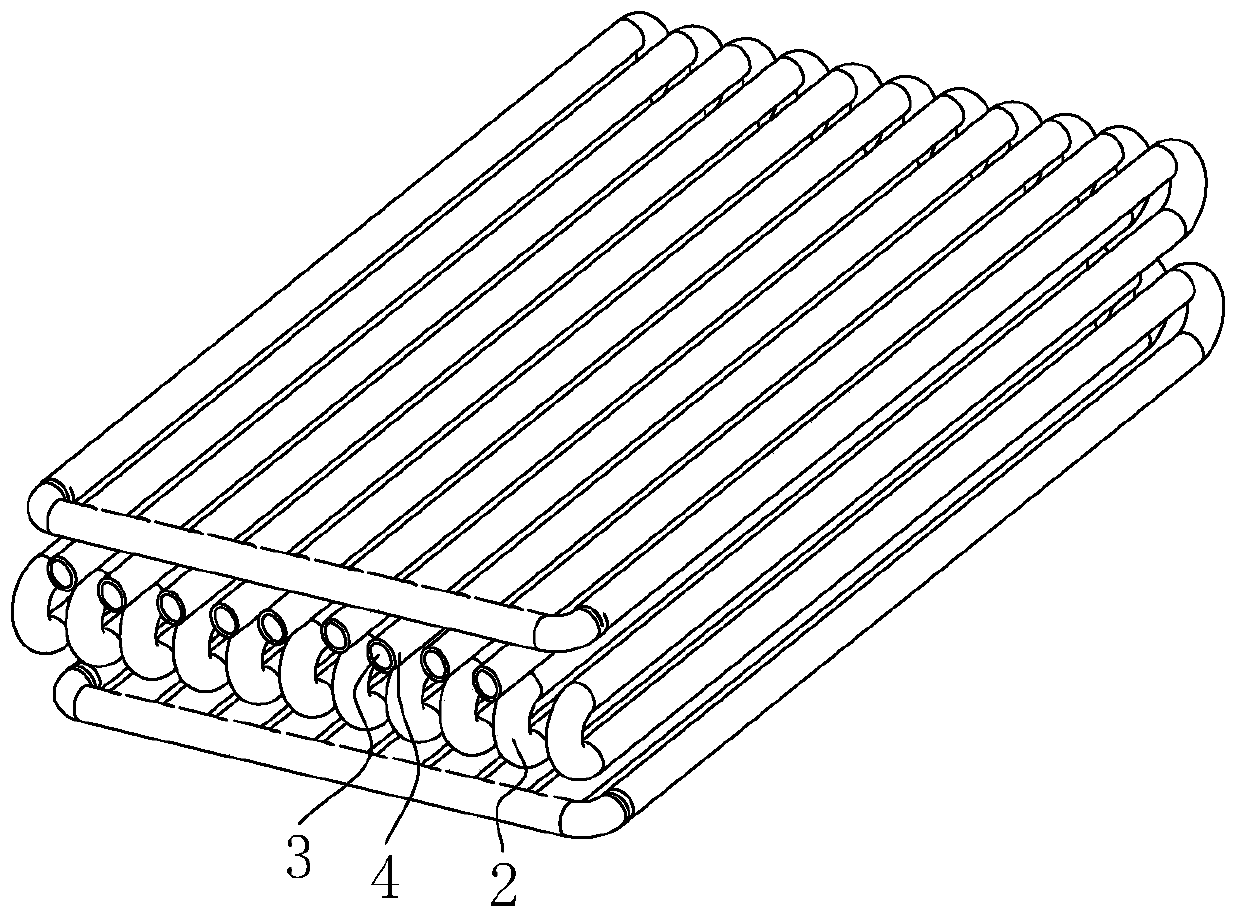

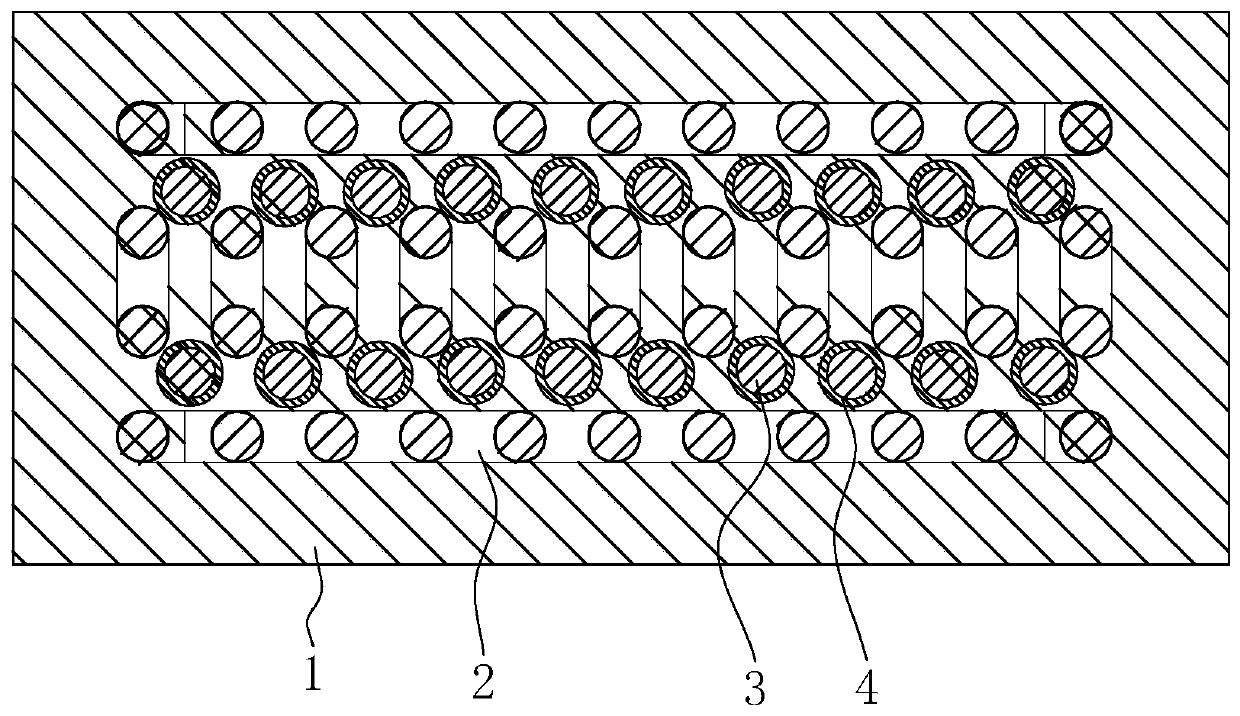

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] A method for reusing construction waste disclosed by the present invention comprises the following steps:

[0043] S1. Sorting and recycling. Classify according to the types of materials obtained from the dismantling of the construction site. The types of classified materials are waste steel bars, concrete blocks, waste wood and other construction waste, and obtain waste steel bars and concrete blocks. Specifically, the construction waste at the construction site can be sorted manually or mechanically.

[0044] Specifically, first use a forklift to separate the large concrete blocks from the construction waste, and control the forklift to put the concrete blocks into the crusher, and the crusher crushes the concrete blocks to form recycled aggregate; use a metal electromagnetic chuck to crush the concrete blocks Or the waste steel bars in the recycled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com