Method for advanced oxidation treatment of refractory organic matters in wastewater by utilizing combination of ferrous ions and dissolved oxygen to activate dithionite

A technology of dithionite and refractory organic matter, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve problems such as water quality deterioration, threats to life and production, and achieve easy operation, Large application potential, convenient transportation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

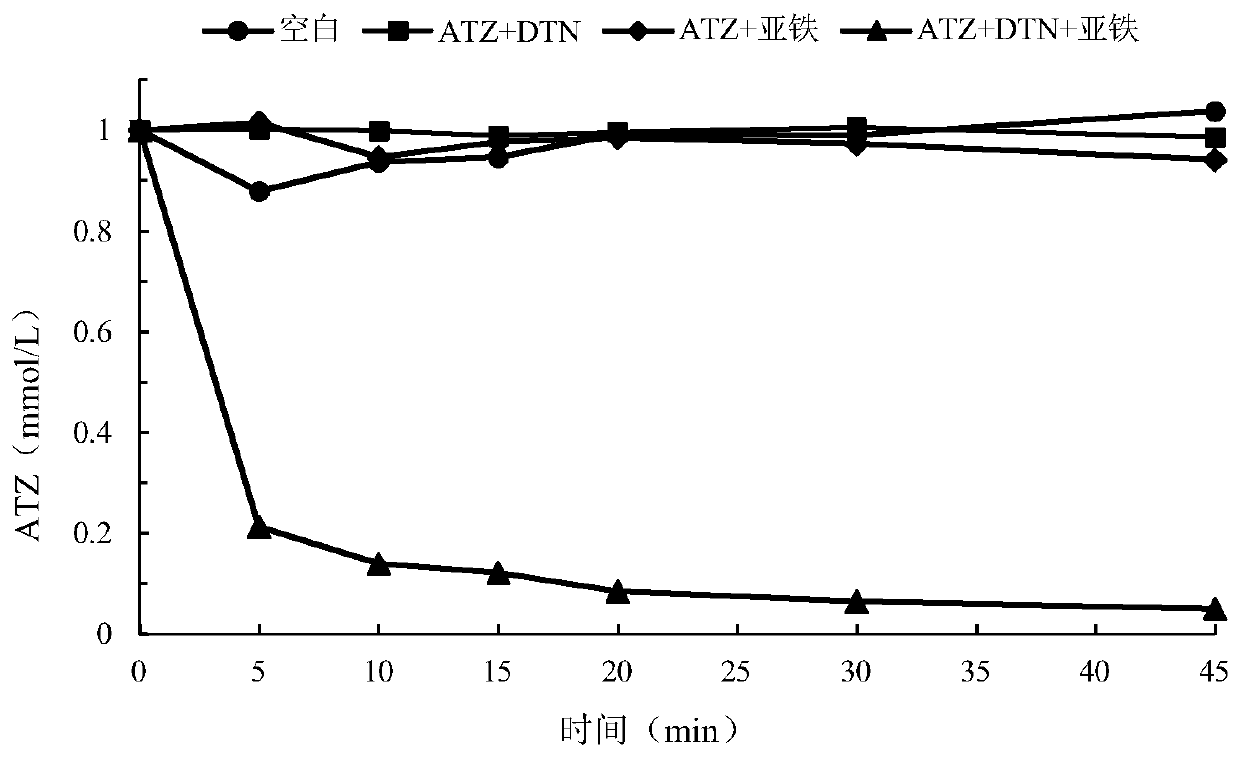

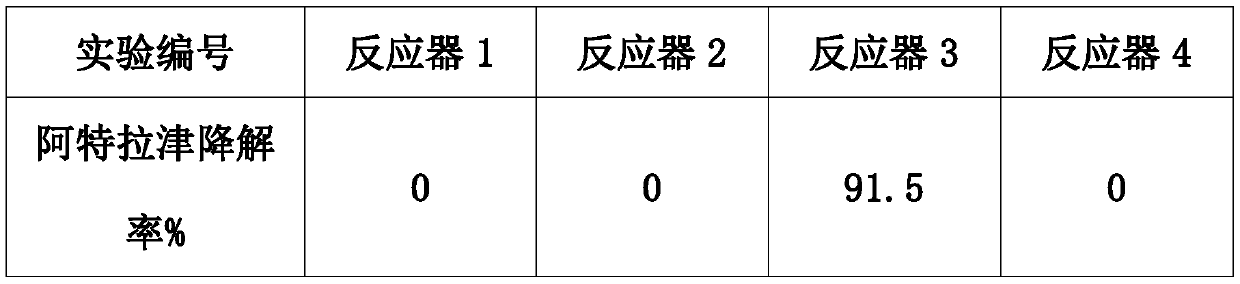

[0024] Example 1: Ferrous ions combined with dissolved oxygen activate dithionite system to degrade atrazine-containing organic wastewater Take four opaque reaction containers, add organic wastewater containing 1 μmol / L atrazine to each of them, and in the reactor The pH is 7.2, the reaction temperature is 30°C, the reaction atmosphere is not controlled, and the four reactors are stirred at a slow speed at the same time to make them react uniformly;

[0025] Add FeSO to reaction vessel 1 4 Solution to make its concentration 0.1mmol / L, add Na to reaction vessel 2 2 S 2 o 4 solution so that its concentration is 0.1mmol / L, in reaction vessel 3, add FeSO 4 solution and Na 2 S 2 o 4 The concentration of the solution was 0.1mmol / L and 0.1mmol / L respectively. Reactor 4 was used as a blank control. After continuing for 20 minutes, the reaction was basically completed. Afterwards, the remaining concentration of atrazine in the wastewater was detected. The detection results are sh...

Embodiment 2

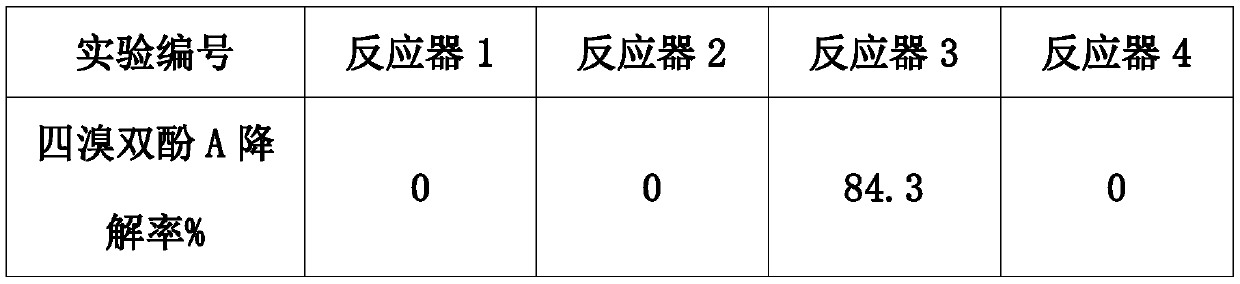

[0029] Example 2: Degradation of tetrabromobisphenol A-containing organic wastewater by ferrous ions combined with dissolved oxygen to activate a dithionite system

[0030] Take four opaque reaction containers, add organic wastewater containing 2 μmol / L tetrabromobisphenol A to each of them, the pH in the reactors is 4.0, the reaction temperature is 30 ° C, and the reaction atmosphere is not controlled. Stir quickly to make it react evenly;

[0031] Add FeCl to reaction vessel 1 3 Solution to make its concentration 0.1mmol / L, add K to reaction vessel 2 2 S 2 o 4 solution so that its concentration is 0.1mmol / L, FeCl is added simultaneously in the reaction vessel 3 3 solution and K 2 S 2 o 4 The concentration of the solution is 0.1mmol / L and 0.1mmol / L respectively, and reactor 4 is used as a blank control, and the reaction continues for 45 minutes to detect the residual concentration of tetrabromobisphenol A in the waste water. The detection results are shown in the follo...

Embodiment 3

[0035] Example 3: Fe 2+ / O 2 Degradation of atrazine-containing organic wastewater with different concentrations of dithionite in the dithionite system

[0036] Take six opaque reaction containers, add organic waste water containing 1 μmol / L atrazine to each of them, the pH in the reactor is 6.9, and the reaction temperature is 30°C, and at the same time, slowly stir the six reactors to make them uniform Reaction; FeSO was added to reaction vessel 1 simultaneously 4 solution and Na 2 S 2 o 4 solution so that its concentration is 0.1mmol / L and 0.01mmol / L respectively, in reaction vessel 2, add FeSO 4 solution and Na2 S 2 o 4 Solution makes its concentration be 0.1mmol / L and 0.05mmol / L respectively, in reaction vessel 3, add FeSO 4 solution and Na 2 S 2 o 4 Solution makes its concentration all be 0.1mmol / L, adds FeSO2 simultaneously in reaction vessel 4 4 solution and Na 2 S 2 o 4 Solution makes its concentration be 0.1mmol / L and 0.2mmol / L respectively, in reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com