Chinese fir core fireproof and flame-retardant environmental-friendly core-board and preparation method thereof

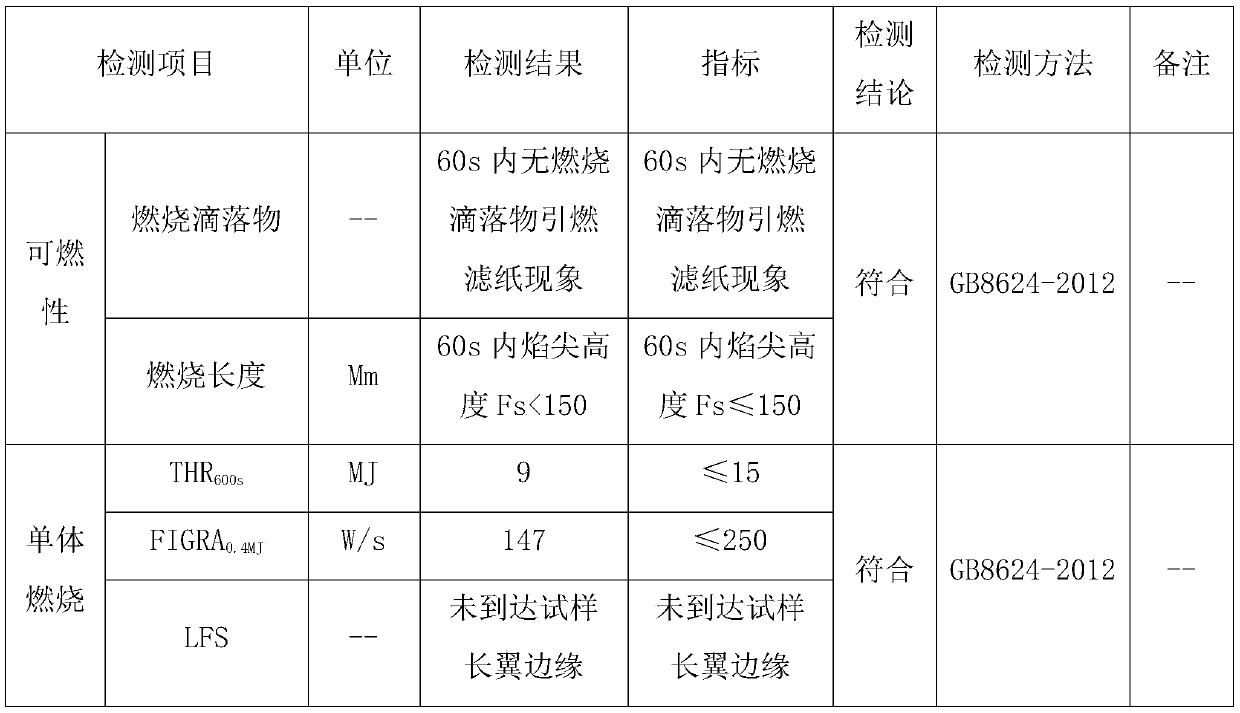

A fire-retardant and blockboard technology, which is applied to wood processing appliances, wood treatment details, and the joining of wooden veneers, can solve problems such as non-flame retardant or delayed burning, and hidden safety hazards, and achieve good fire resistance. Burning effect, the effect of increasing structural force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the following specific examples.

[0032] The preparation method of a Chinese fir core fire-resistant, flame-retardant and environmentally friendly blockboard provided by the present invention comprises the following steps:

[0033] (1) Saw fir into long strips with a length of 200mm-800mm, a width of 30mm-70mm, and a thickness of 8mm-15mm, and pile them up and send them to the drying room for baking so that the moisture content of the strips reaches 12. within %;

[0034] (2) Use a comb machine to comb the two ends of the slats, and then butt the slats into 2470mm slats;

[0035] (3) Preparation of adhesive A: 100 parts by weight of urea-formaldehyde resin, 30 parts by weight of fire retardant, and 25 parts by weight of flour were fully stirred and evenly prepared into adhesive A for subsequent use;

[0036] (4) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com