Sealed heating device with integrated clamping flange and using method of sealed heating device

A sealed heating and integrated technology, applied in the direction of tobacco, etc., can solve the problems of insufficient natural overflow of smoke aerosol and insufficient smoke, and achieve the effect of increasing release, increasing heating temperature, and increasing heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

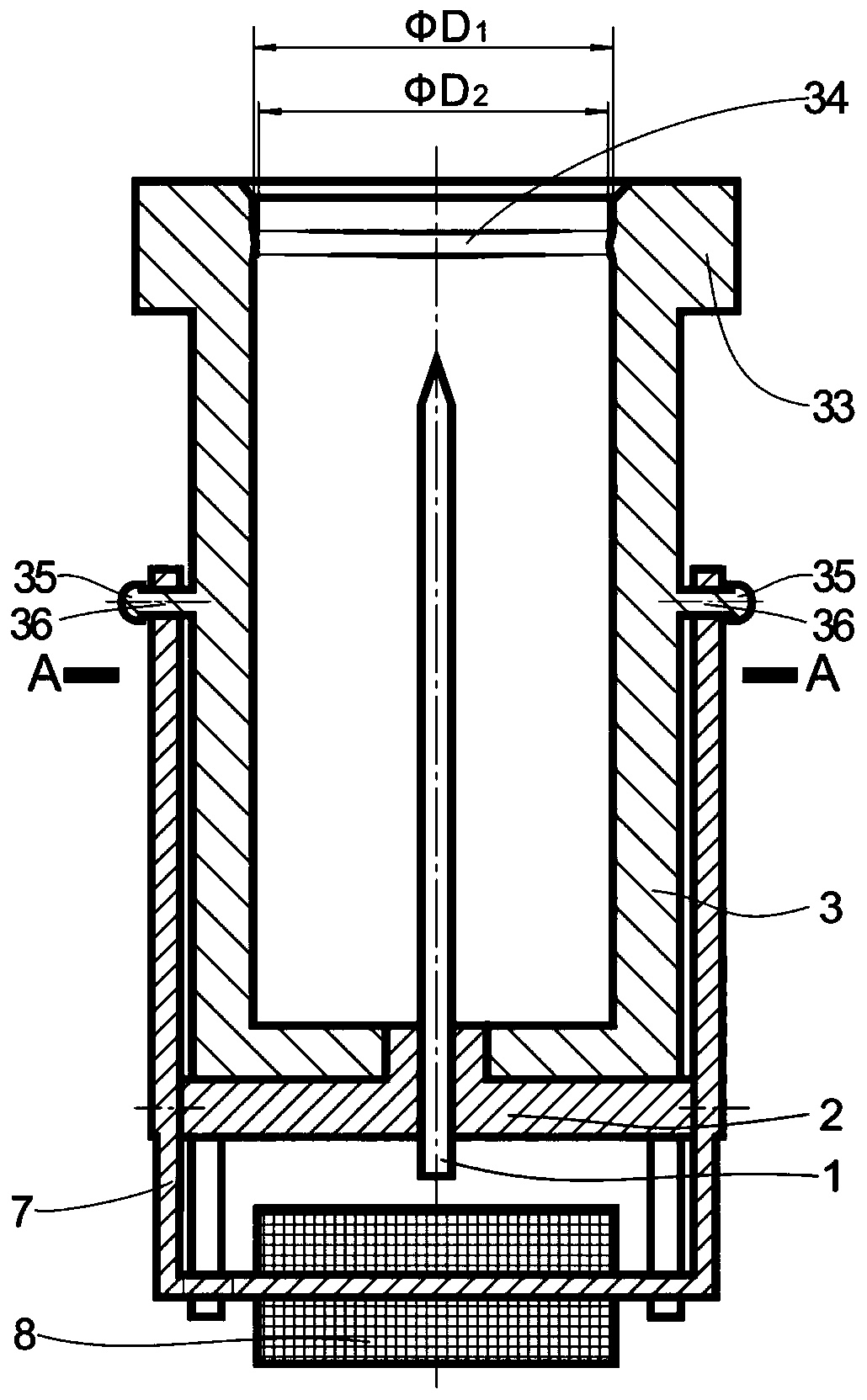

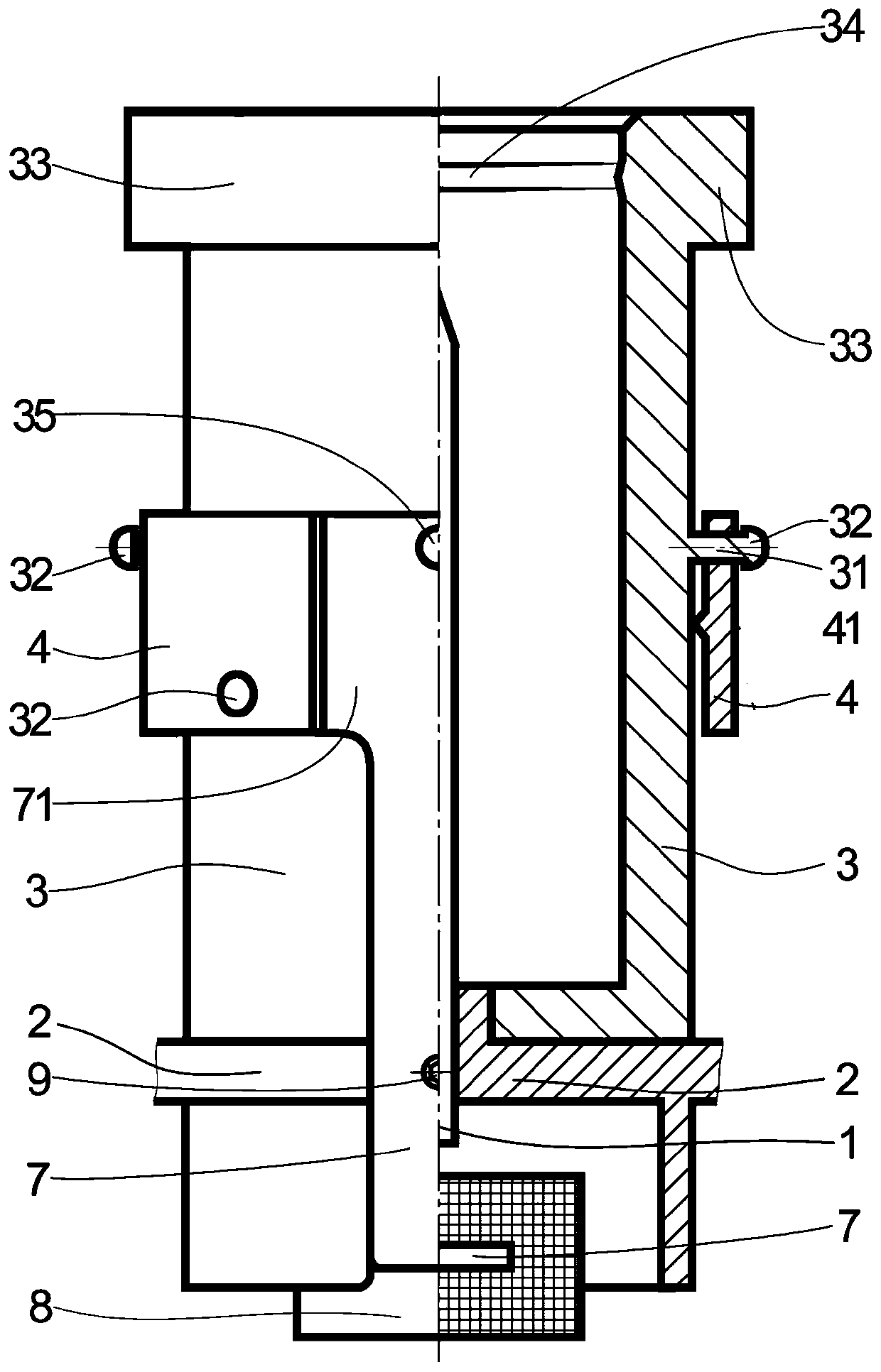

[0059] like figure 1 As shown, a sealed heating device with a double-sided vibrating smoke outlet assembly and a clamping rib, the sealed heating device includes a sealed heating assembly and a double-sided vibrating smoke outlet assembly;

[0060] The sealed heating assembly includes:

[0061] The inside of the flexible sealing sleeve 3 is a sealing cavity, and the inner wall of the port 33 of the sealing cavity at the upper end of the sealing sleeve 3 has an integrated clamping rib 34 , and the clamping rib 34 is in the shape of a ring.

[0062] The inner wall of the sealing sleeve 3 has an integrated clamping rib 34;

[0063] A central heating element 1, which is arranged inside the sealed cavity;

[0064] The double-sided vibration smoke assembly includes:

[0065] A vibrating mass 4 arranged on the periphery of the sealed heating chamber;

[0066] The power supply device provides power for the vibrating mass 4 to press the side wall of the flexible sealing sleeve 3 in...

Embodiment 2

[0086] The method of using the sealed heating device with double-side vibrating smoke outlet assembly and clamping ribs in Example 1 is as follows:

[0087] 1. Cigarette stick insertion stage: when a cigarette to be smoked is inserted into the smoking set from the port 33 of the sealed cavity, the clamping rib 34 is deformed, clamps the cigarette, and seals the sealed cavity circumferentially.

[0088] 2. Suction stage: start the heating element, then start the power supply device, the vibration block 4 starts to reciprocate and squeeze the side wall of the sealing sleeve 3 from both sides, and the smoke in the sealed cavity is squeezed out.

[0089] When the cigarette is heated rapidly from the ambient temperature to the highest temperature during the initial period of time, the air carried in the shredded tobacco of the cigarette is rapidly heated, and the pressure increases rapidly, together with the smoke aerosol generated by the high temperature at the same time, The filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com