Walnut green husk removing, cleaning, drying, cracking and kernel extracting all-in-one processing production device and method

A production line and green skin technology, which is applied in the field of agricultural machinery, can solve the problems of backward processing technology and restrictions on the deep processing of walnut oil and walnut juice, and achieve the effect of improving the peeling rate, reducing the broken rate, and improving the quality of walnuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

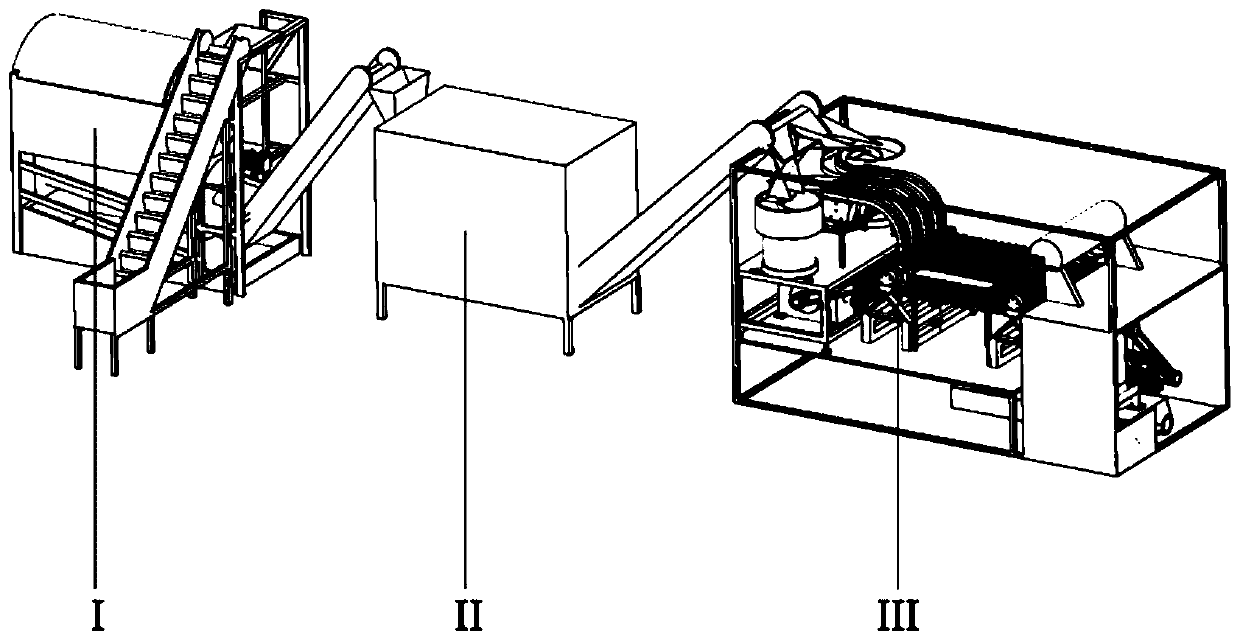

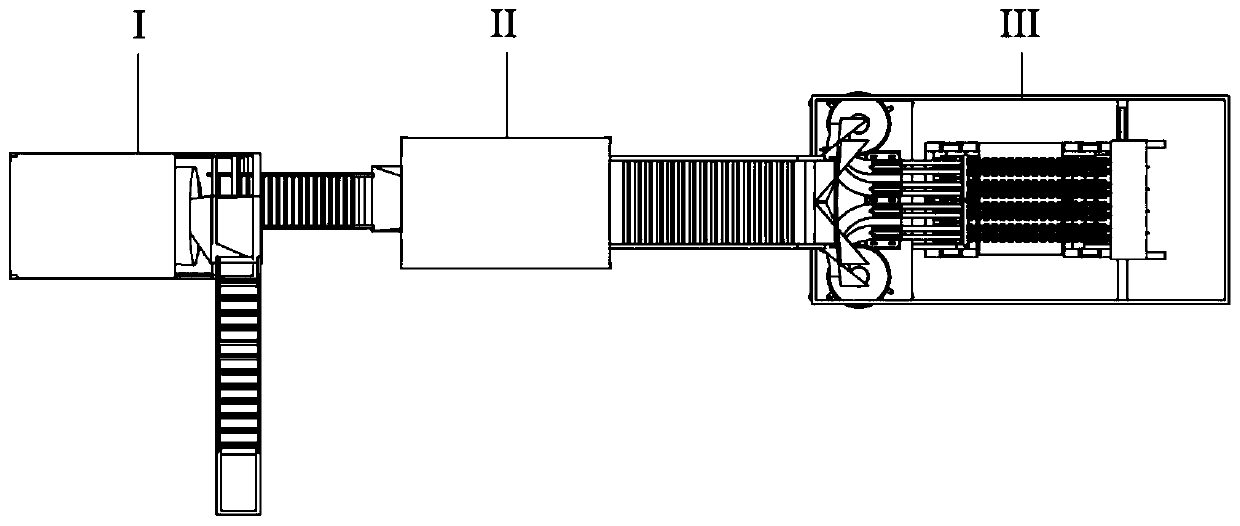

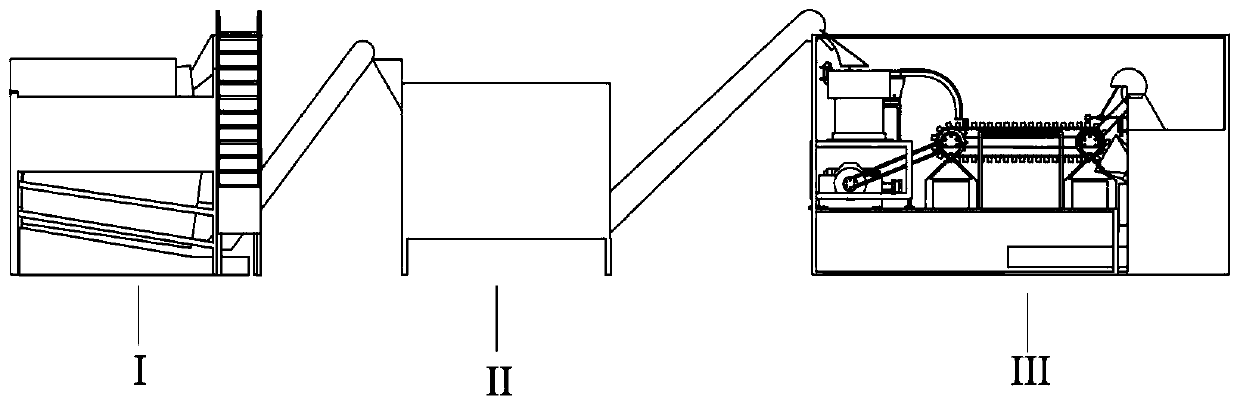

[0056] Attached below Figure 1-Figure 3 The present invention is described in detail, and concretely, the structure is as follows:

[0057] This embodiment provides an integrated processing production line for walnut peeling, cleaning, drying, shell breaking, and kernel extraction, such as Figure 1-Figure 3 As shown, including peeling and cleaning device I, microwave electric heating drying device II and kernel-breaking device III, which are set in turn, integrating functions such as feeding, walnut peeling, walnut cleaning, drying, and breaking shell and taking kernels. , Improve the efficiency of walnut processing. Specifically, as Figure 4 As shown, the green peeling and cleaning device 1 includes a feeding mechanism I-01, a green peeling device I-02, a friction cleaning device I-03, the feeding mechanism I-01 is connected with the green peeling device I-02, and the green peeling device I- 02 is connected to the friction cleaning device I-03.

[0058] like Figure ...

Embodiment 2

[0084] This embodiment provides an integrated processing method for walnut peeling, washing, drying, shell breaking, and kernel extraction, including: inputting the material to be processed into a hopper at a certain rate; cutting and rubbing the conveyed material to achieve initial peeling; First peeled walnuts are subjected to steel brush friction and water cleaning; microwave and electric heating drying are performed on peeled walnuts; Shell effect; the material is separated from the shell and kernel of the walnut through the negative pressure separation device, so as to realize the integration of peeling, cleaning, drying, breaking the shell and taking the kernel.

[0085] specific,

[0086] (1) Force analysis of the self-adaptive opposite oblique cut green peeling system: According to the production requirements, the radius, rotation speed and inclination of the green peel drum determine the production capacity of the green peel walnut. Speed directly affects the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com