A kind of sludge biofuel production equipment

A biofuel and production equipment technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problem of less production equipment, and achieve the effects of convenient opening, reliability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

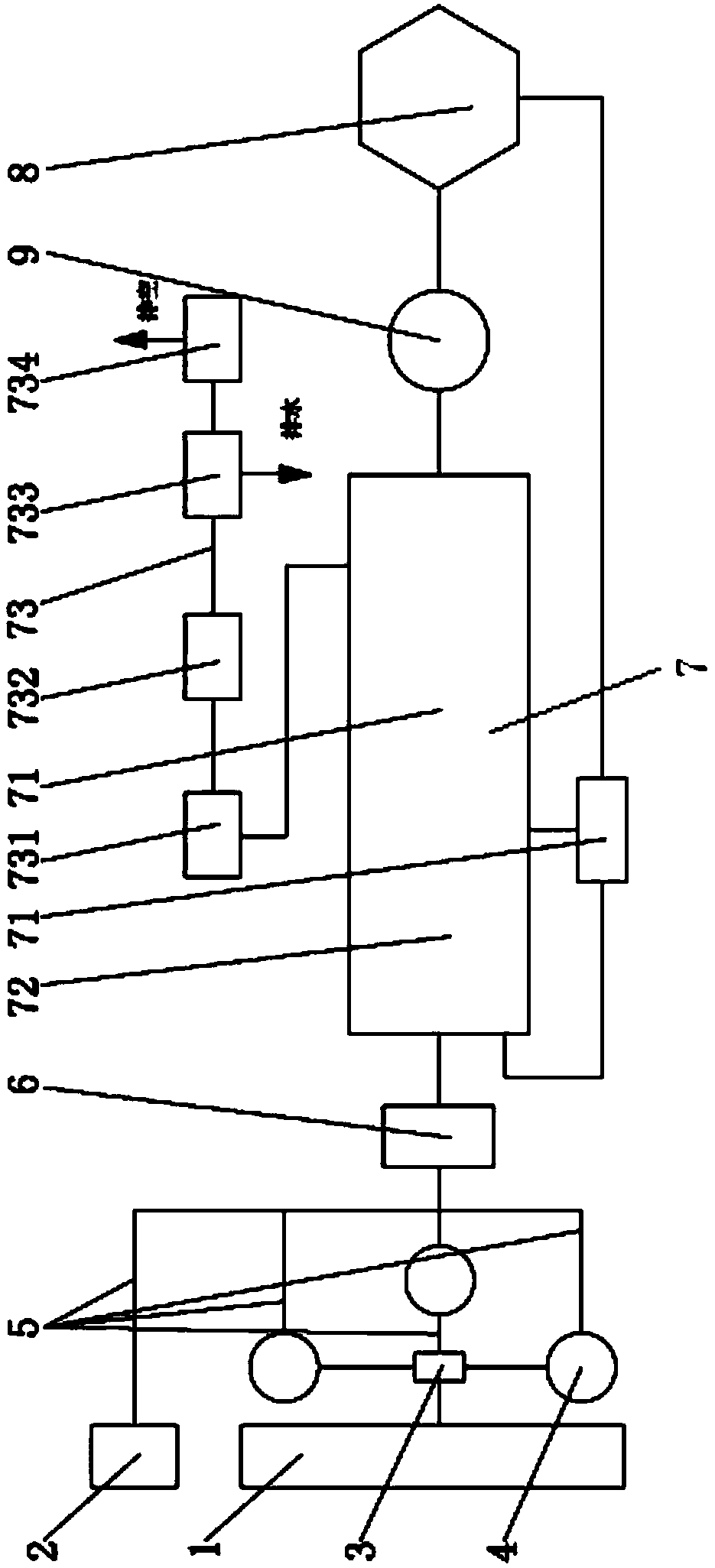

[0057] In order to carry out batch automatic production and preparation of sludge biofuel, the present invention designs a sludge biofuel production equipment which integrates sludge and blended material unloading, transportation, proportioning, drying, compression molding and waste gas treatment ;

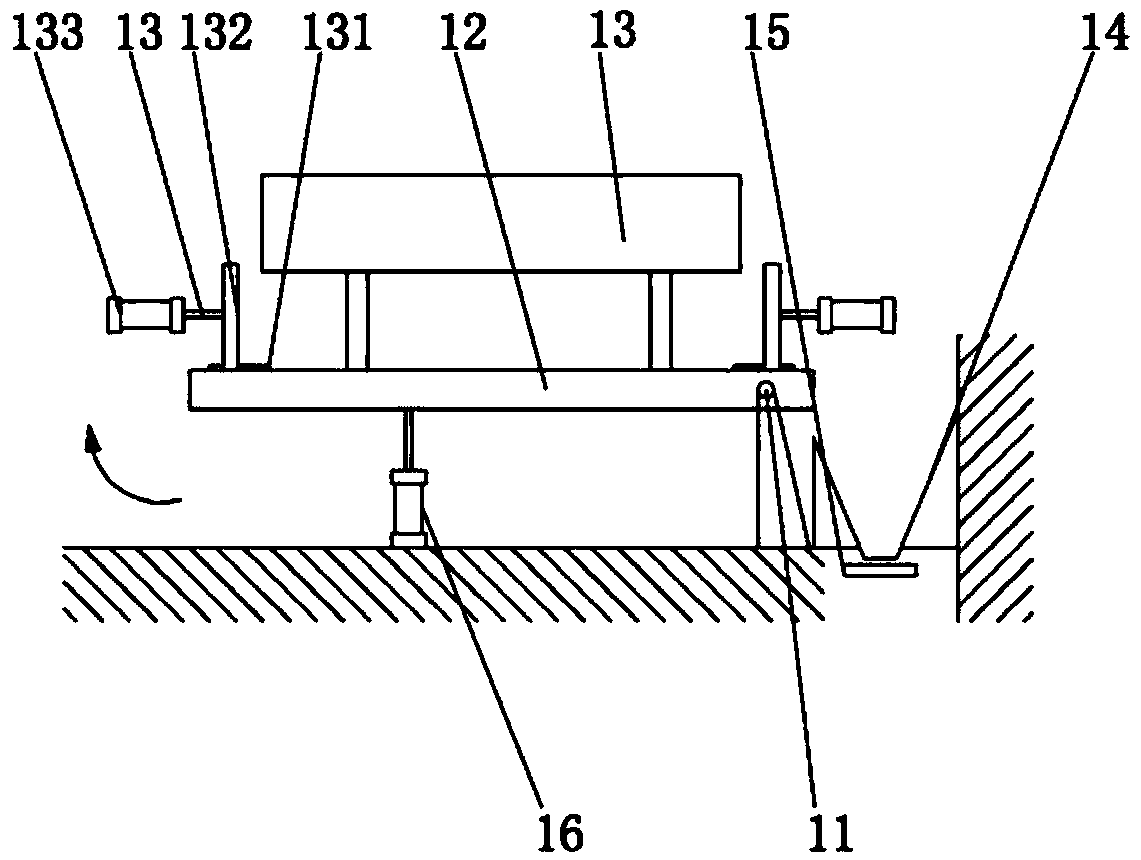

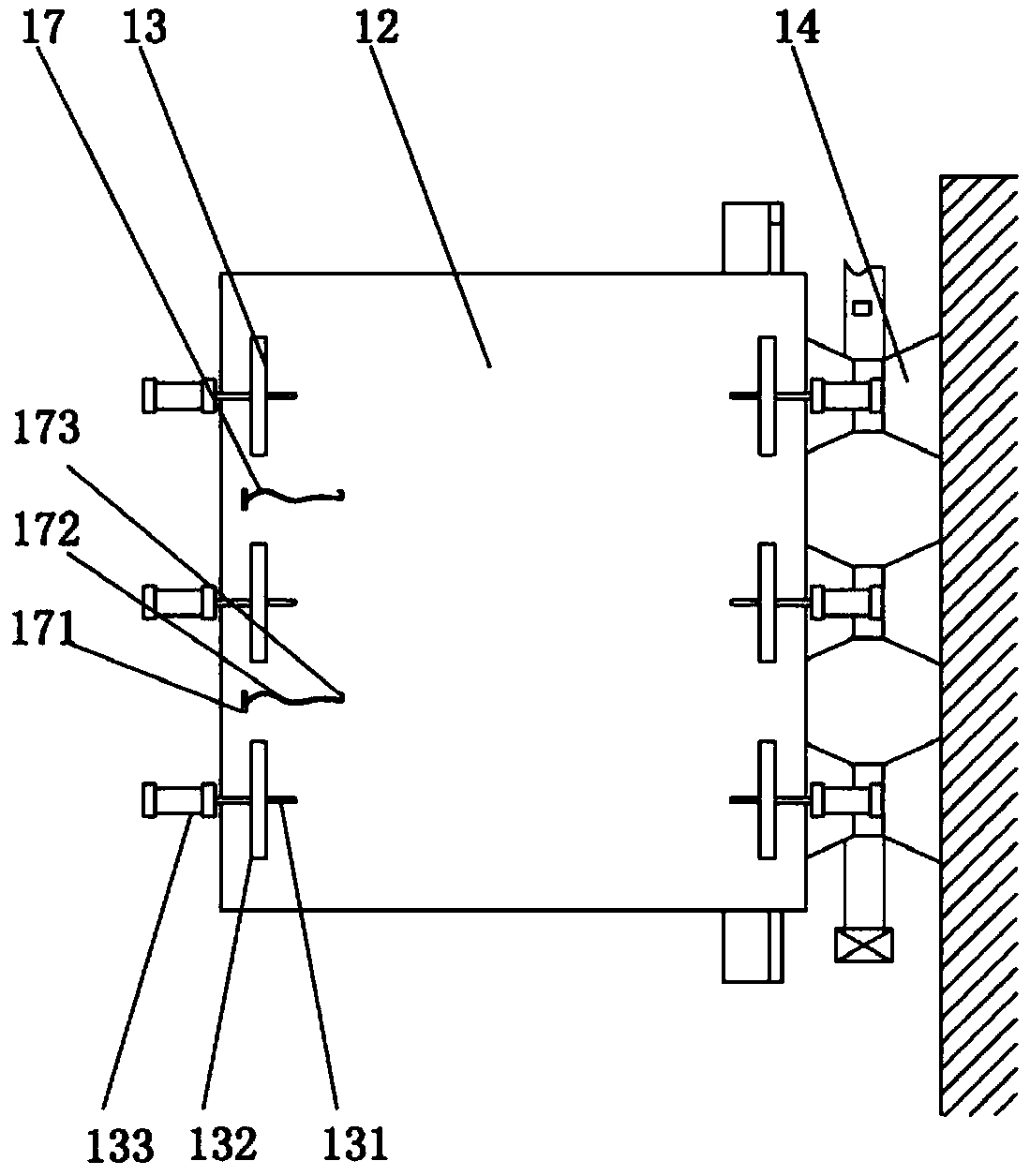

[0058] Such as figure 1 As shown, the equipment includes blending material unloading truck and conveying device 1, sludge bin and conveying device 2, lifting distributor 3, N silos 4, N+1 belt conveying devices 5, agitator 6, and drying system 7. Finished product bin 8 and fuel molding machine 9; N is the number of blending materials, N≥1. In this example, blending materials include wood chips, coke powder and conditioner, so the corresponding number of bins is 3 ;

[0059] Blended material unloading vehicle and conveying device 1 is used to unload wood chips, coke powder and conditioning agent from the loading truck in sequence and transport them to the lifting distributor 3; s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com