Milling parameter optimization method for thin-walled workpiece

A technology of milling processing and optimization methods, applied in multi-objective optimization, neural learning methods, design optimization/simulation, etc., can solve problems such as difficulty in guaranteeing processing quality, low efficiency, and too conservative processing parameters, and achieve the effect of improving search capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

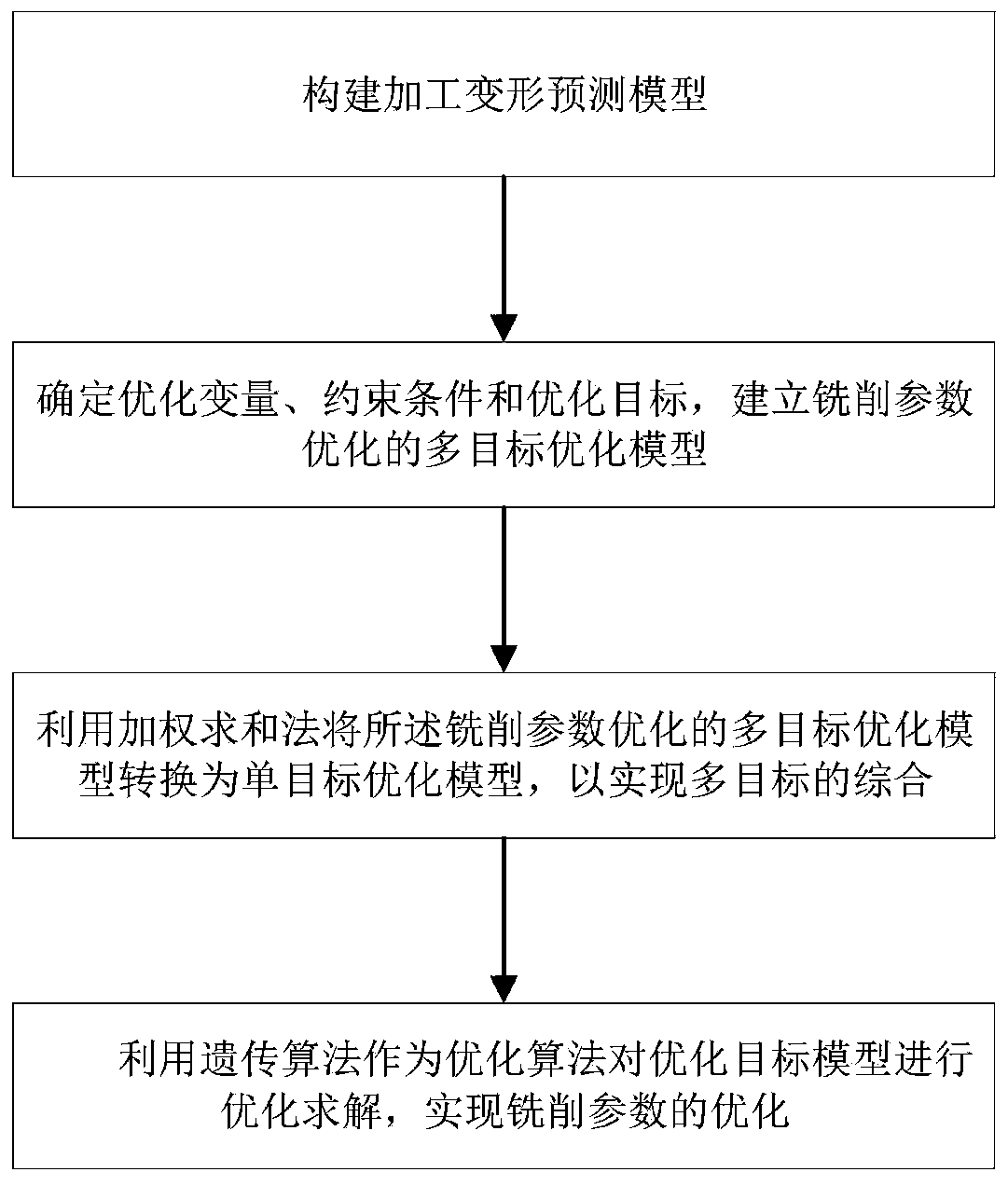

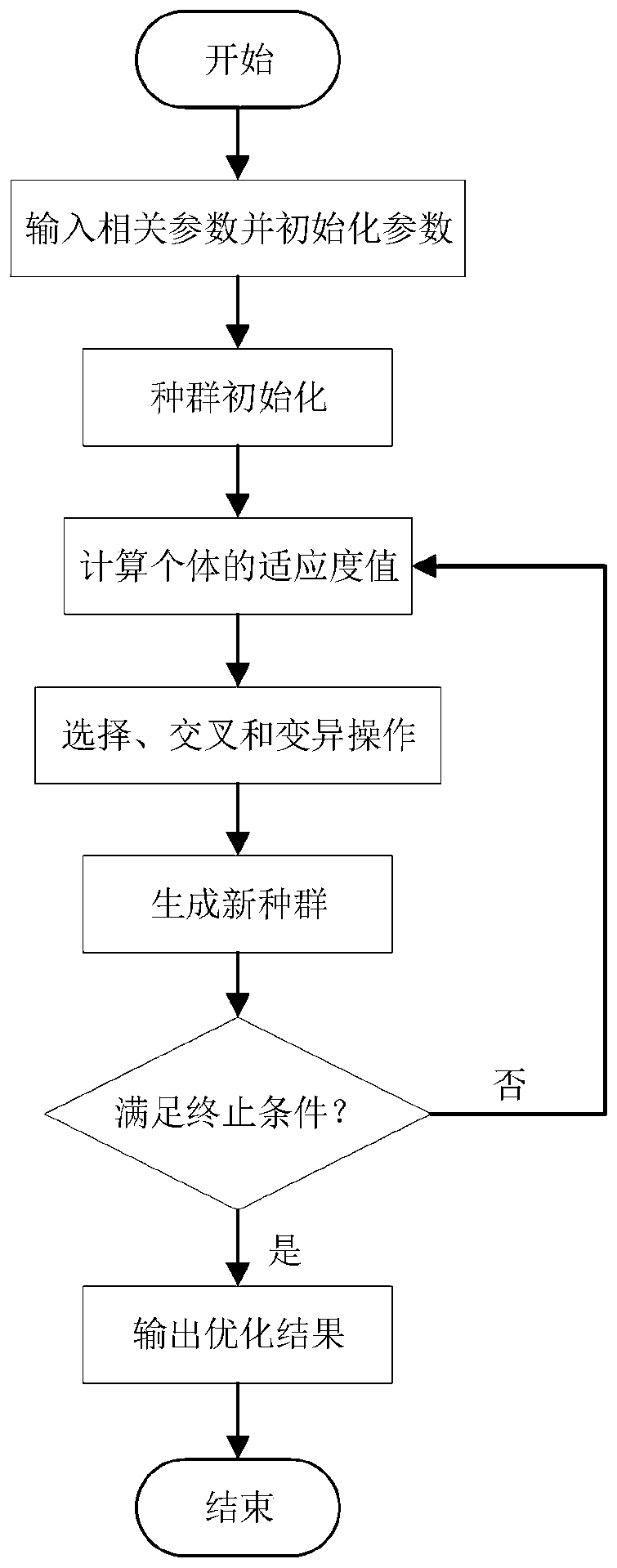

[0023] Such as Figure 1-2 shown.

[0024] figure 1 It is a flow chart of a thin-walled part milling parameter optimization method of the present invention. Such as figure 1 As shown, a thin-walled milling parameter optimization method includes the following steps:

[0025] Step 1, constructing a processing deformation prediction model;

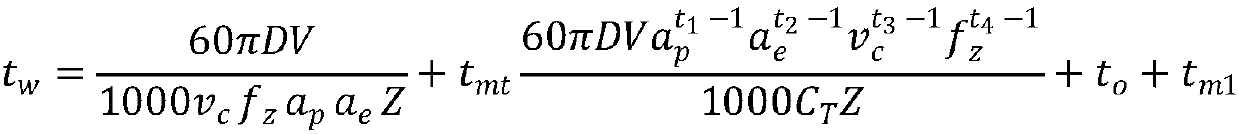

[0026] For CNC machine tools, the relationship between milling cutting parameters and milling deformation is nonlinear, and the functional relationship between them cannot be established by traditional theoretical analysis methods. However, the BP neural network does not need to consider their complex structures, as long as Through the data, the system model composed of milling parameters and machining deformation can be obtained. The relationship data between cutting parameters and maximum mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com