Tool for quickly forming radial temperature gradient distribution

A gradient distribution and radial temperature technology, applied in optics, instruments, heat exchange equipment, etc., can solve the problems of not meeting the requirements of imaging quality and poor uniformity of optical film thickness, so as to improve the production process level and control the temperature distribution , Easy to operate and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

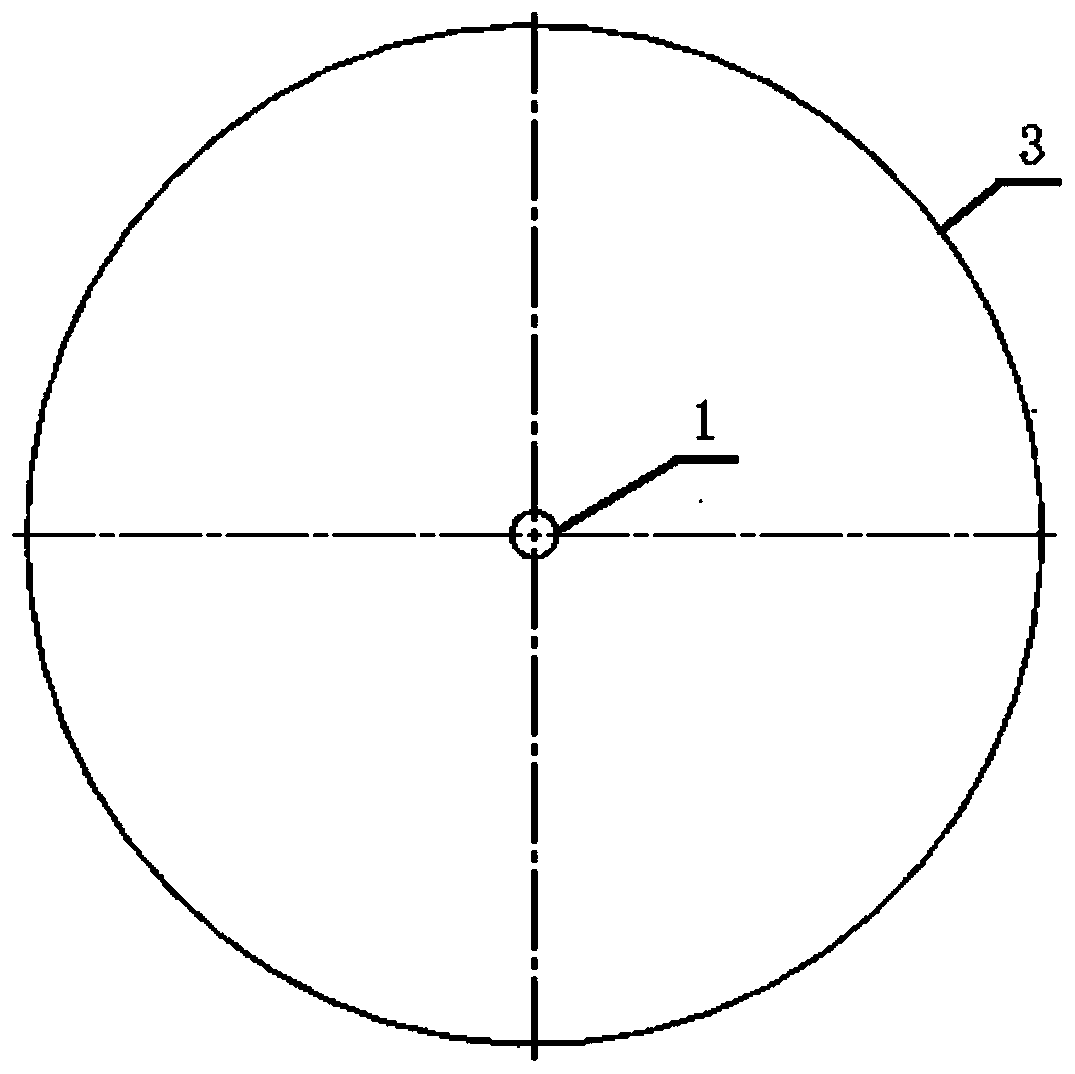

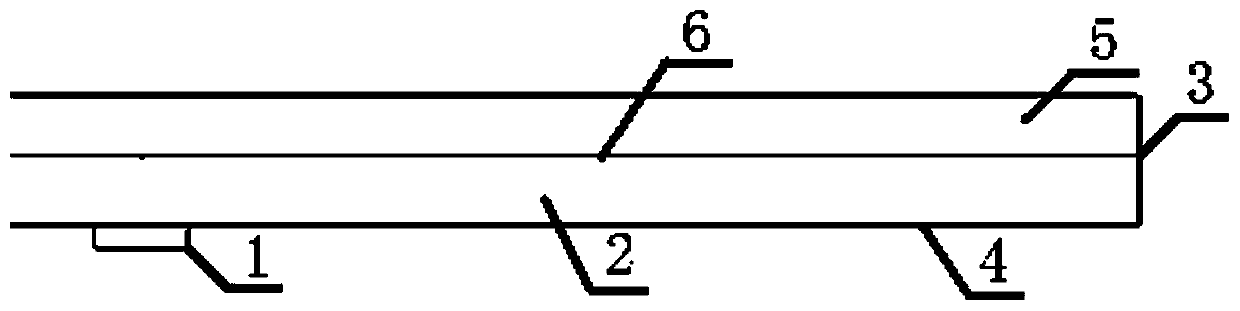

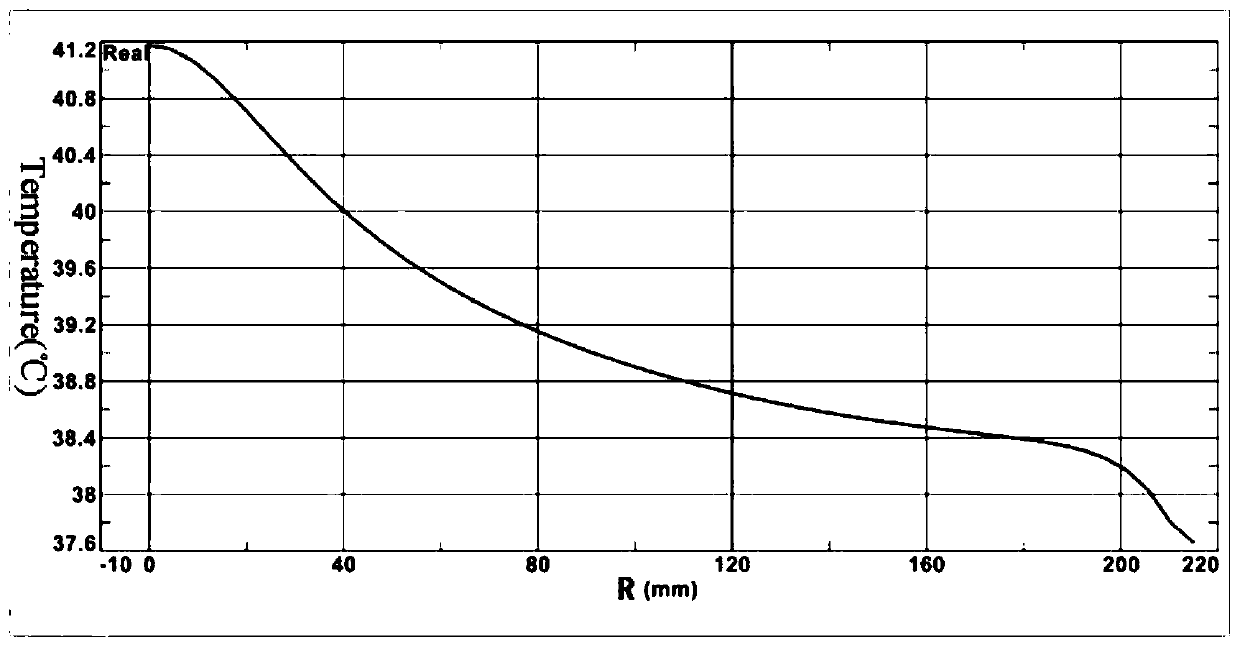

[0024] The top view of tooling 1 is as follows figure 1 As shown, the size of the circular bottom 1 is Φ20mm, and the size of the working platform 3 is Φ430mm. Tooling 1 side view as figure 2 As shown, the height of the circular bottom 1 is 5mm, the shape of the heat transfer body 2 is cylindrical, and the thickness is 15mm, the size of the quartz substrate 5 is Φ430mm*13mm, and the outer surface of the heat transfer body 2 is insulated with a heat insulating foam cotton insulation layer 4 A thin layer of heat-conducting silicone grease 6 is coated between the quartz substrate 5 and the working platform 3 to ensure surface contact. The material of the tooling is 6061 aluminum alloy, the ambient temperature is 25, the temperature of the heat source is 60 °C, and the temperature is kept for one hour to make the tooling and the environment reach thermal equilibrium. Test the surface temperature distribution on the quartz substrate 5, the result is as follows image 3 As shown,...

Embodiment 2

[0026] The top view of tooling 2 is as follows figure 1 As shown, the size of the circular bottom 1 is Φ20mm, and the size of the working platform 3 is Φ430mm. Tooling 2 side view as Figure 4 As shown, the height of the circular bottom 1 is 5mm, the shape of the heat transfer body 2 is V-shaped, and the height is 35mm, the size of the quartz substrate 5 is Φ430mm*13mm, and the outer surface of the heat transfer body 2 is insulated with a thermal insulation foam cotton insulation layer 4 A thin layer of heat-conducting silicone grease 6 is coated between the quartz substrate 5 and the working platform 3 to ensure surface contact. The material of the tooling is 6061 aluminum alloy, the ambient temperature is 25, the temperature of the heat source is 60 °C, and the temperature is kept for one hour to make the tooling and the environment reach thermal equilibrium. Test the surface temperature distribution on the quartz substrate 5, the result is as follows Figure 5 As shown, t...

Embodiment 3

[0028] The top view of tooling 3 is as follows figure 1 As shown, the size of the circular bottom 1 is Φ20mm, and the size of the working platform 3 is Φ430mm. Tooling 2 side view as Figure 6 As shown, the height of the circular bottom 1 is 5mm, the shape of the heat transfer body 2 is bowl-shaped, the height is 35mm, the radius of curvature is 700mm, the size of the quartz substrate 5 is Φ430mm*13mm, and the outer surface of the heat transfer body 2 is made of heat-insulating foam cotton 4 Carry out heat preservation, apply a thin layer of heat-conducting silicone grease 6 between the quartz substrate 5 and the working platform 3 to ensure surface contact, the material of the tooling is 6063 aluminum alloy, the ambient temperature is 25, the temperature of the heat source is 60 °C, and the temperature of the heat source is 60 °C for one hour to make the tooling and the environment Reach thermal balance, test the upper surface temperature distribution of quartz substrate 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com