Raspberry composite alcohol-free wine and preparation method thereof

A raspberry and alcohol-free technology, which is applied in the field of raspberry compound non-alcoholic wine and its preparation, can solve the problems of difficult production of high-quality raspberry fruit wine, high acidity and sourness of raspberry fruit, and achieve short aging time, soft and harmonious taste, taste unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of raspberry compound non-alcoholic wine, comprising the following steps:

[0032] 1) Preparation of fruit pulp: Remove disease insects, mildew, rotten fruits, leaves and branches from ripe raspberries, grapes, blueberries, berry and figs, then crush them separately, separate and remove fibers, and obtain puree of pulp;

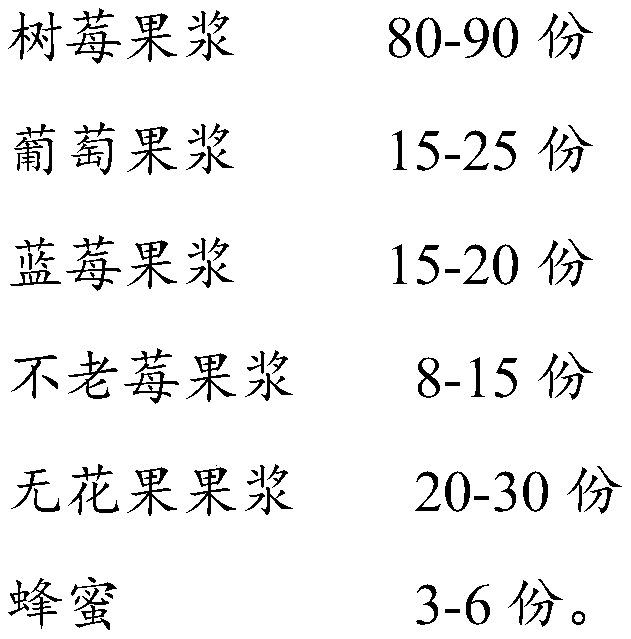

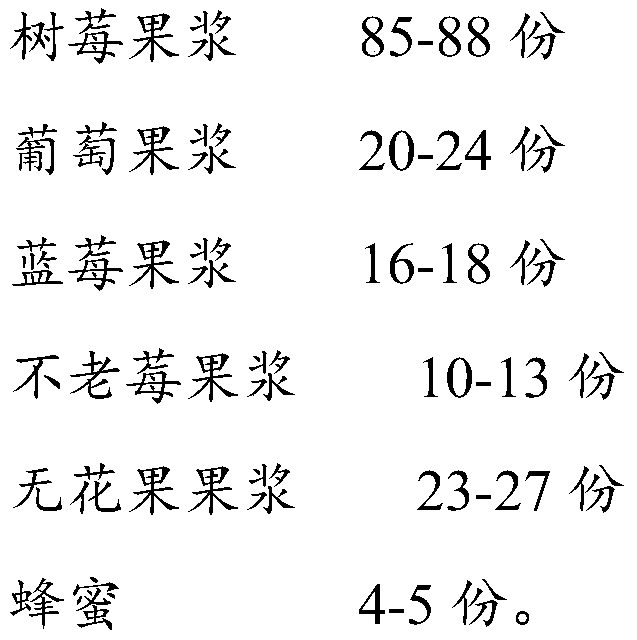

[0033] 2) Enzymatic hydrolysis: mix 80 parts of raspberry pulp, 15 parts of grape pulp, 15 parts of blueberry pulp, 8 parts of berry pulp, and 20 parts of fig pulp, and then add the total weight of pulp pulp while stirring 0.03% pectinase, enzymatic hydrolysis for 40 minutes, and the enzymatic hydrolysis temperature is 25°C to obtain the enzymatic hydrolysis solution;

[0034] 3) Fermentation: Add 0.02% dry yeast and 4 parts of honey to the enzymolysis liquid, mix evenly, ferment at 28°C for 3 days, then ferment at 20°C for 10 days, and filter after fermentation , to obtain fermentation broth;

[0035] 4) Distillation: the fermen...

Embodiment 2

[0039] A preparation method of raspberry compound non-alcoholic wine, comprising the following steps:

[0040] 1) Preparation of fruit pulp: Remove disease insects, mildew, rotten fruits, leaves and branches from ripe raspberries, grapes, blueberries, berry and figs, then crush them separately, separate and remove fibers, and obtain puree of pulp;

[0041] 2) Enzymatic hydrolysis: Mix 90 parts of raspberry pulp, 25 parts of grape pulp, 20 parts of blueberry pulp, 15 parts of berry pulp, and 30 parts of fig pulp evenly, then add the total weight of pulp pulp while stirring 0.04% pectinase, enzymatic hydrolysis for 60 minutes, and the enzymatic hydrolysis temperature is 30°C, to obtain the enzymatic hydrolysis solution;

[0042] 3) Fermentation: Add 0.04% dry yeast and 5 parts of honey to the enzymolysis solution, mix evenly, ferment at 28°C for 3 days, then ferment at 22°C for 15 days, after the fermentation is completed Filtration to obtain fermented liquid;

[0043] 4) Dist...

Embodiment 3

[0047] A preparation method of raspberry compound non-alcoholic wine, comprising the following steps:

[0048] 1) Preparation of fruit pulp: Remove disease insects, mildew, rotten fruits, leaves and branches from ripe raspberries, grapes, blueberries, berry and figs, then crush them separately, separate and remove fibers, and obtain puree of pulp;

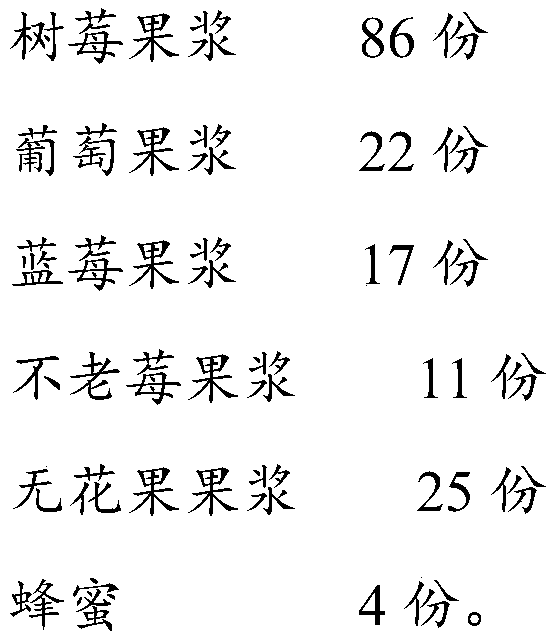

[0049] 2) Enzymatic hydrolysis: mix 86 parts of raspberry pulp, 22 parts of grape pulp, 17 parts of blueberry pulp, 11 parts of berry pulp, and 25 parts of fig pulp, and then add the total weight of pulp pulp while stirring 0.04% pectinase, enzymatic hydrolysis for 50 minutes, and the enzymatic hydrolysis temperature is 28°C, to obtain the enzymatic hydrolysis solution;

[0050] 3) Fermentation: Add 0.03% dry yeast of the total weight of pulp pulp and 4 parts of honey to the enzymolysis liquid, mix evenly, ferment at 29°C for 5 days, then ferment at 22°C for 12 days, and filter after fermentation , to obtain fermentation broth;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com