Power conversion unit and mining frequency converter

A conversion unit and frequency converter technology, applied in the field of frequency converters, can solve the problems of increasing the difficulty of dismantling the faulty power conversion unit, difficult disassembly and assembly of the power conversion unit, prolonging the downtime of equipment failure, etc., achieving shortened downtime due to failure, improved performance, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

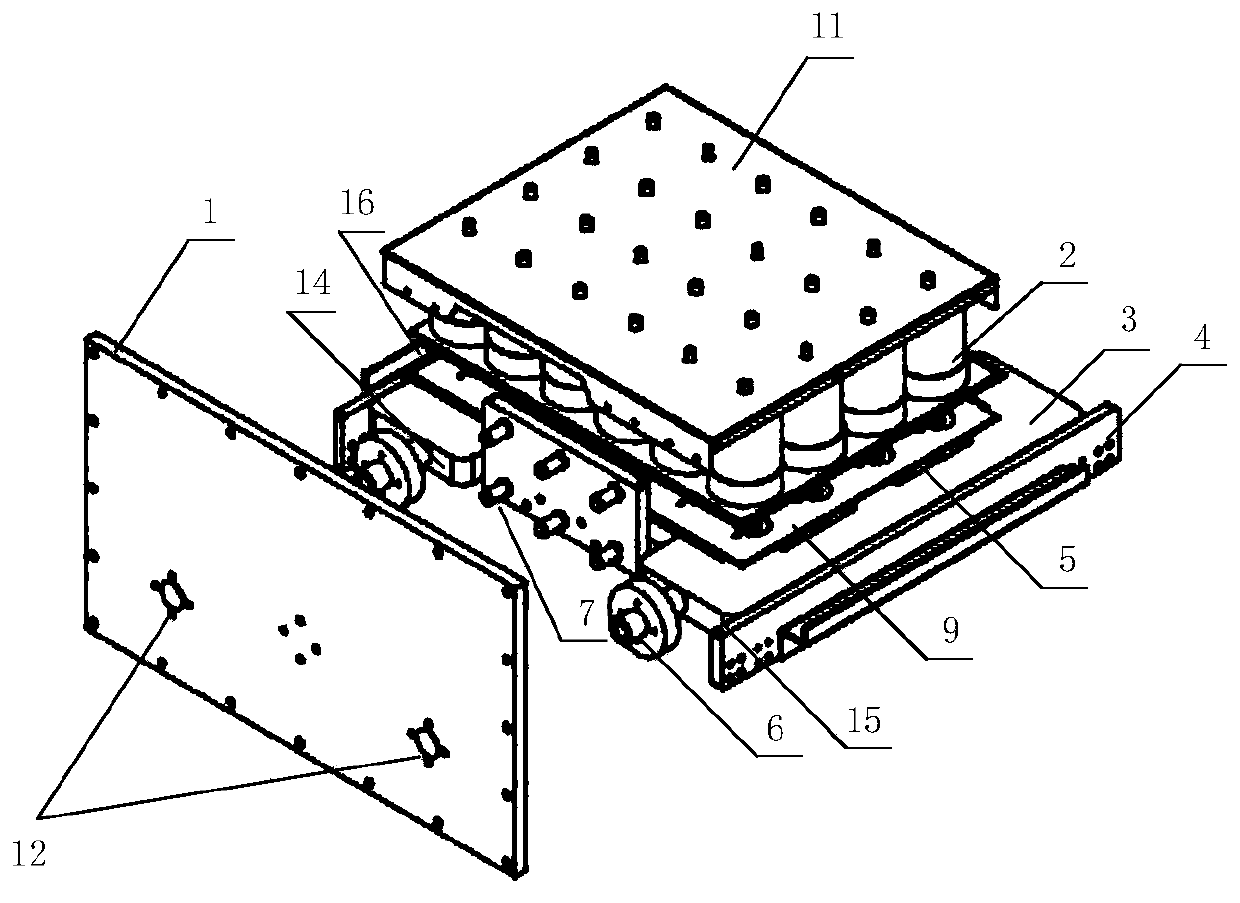

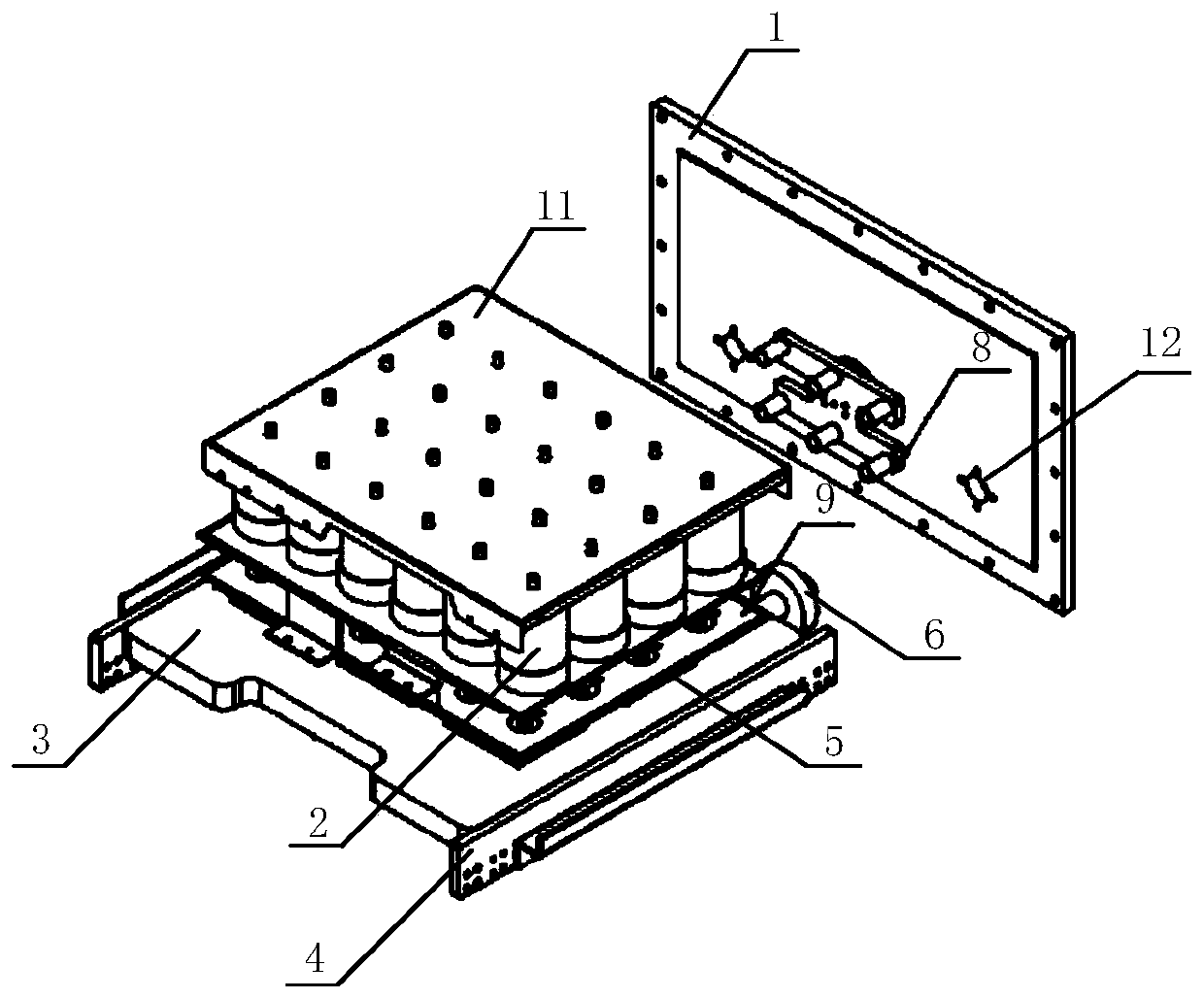

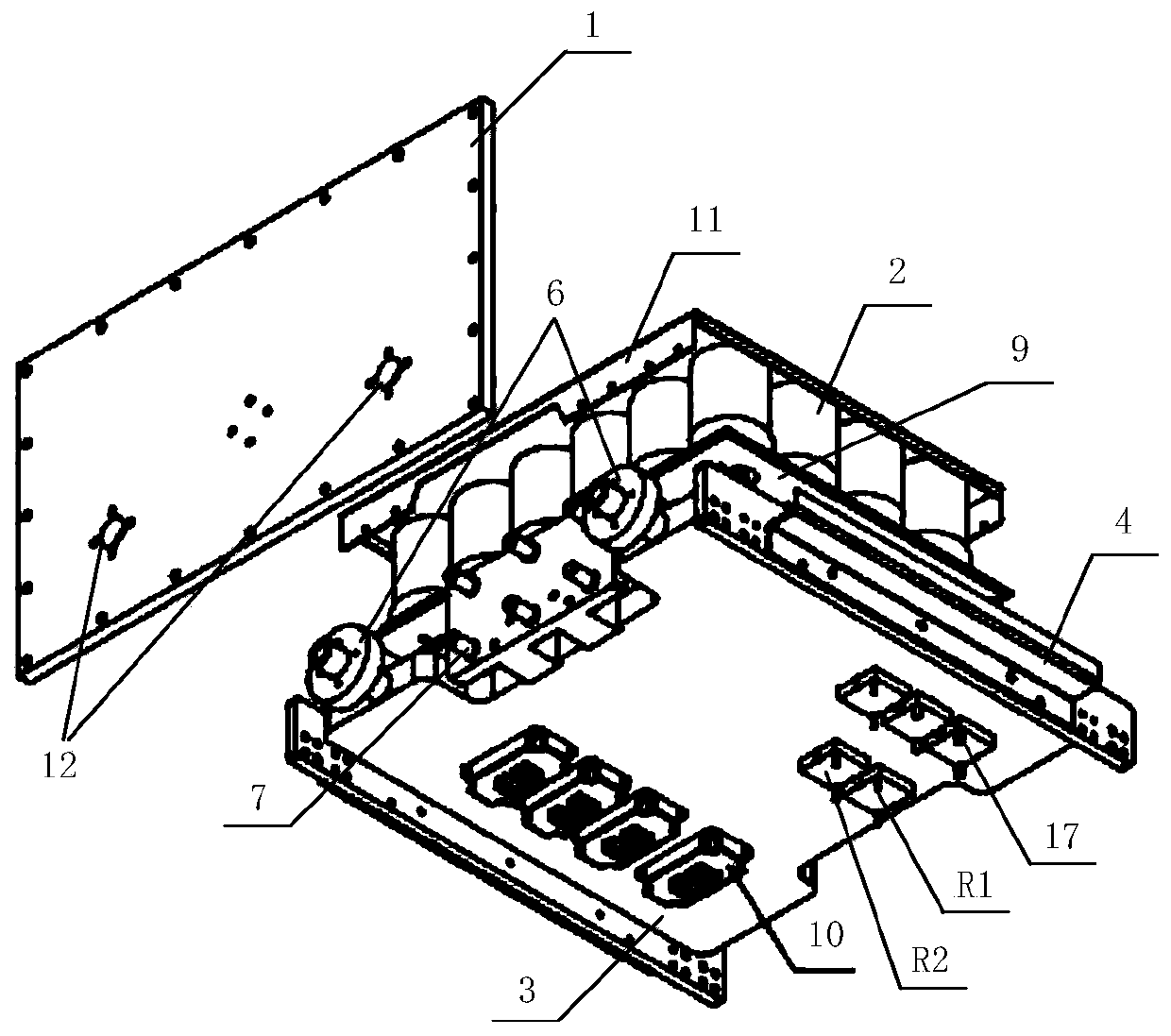

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present disclosure, the present disclosure will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Embodiments of the present disclosure will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but are not intended to limit the present disclosure.

[0020] Words such as "comprising" or "comprising" used in the present disclosure mean that the elements preceding the word cover the elements listed after the word, and the possibility of also covering other elements is not excluded. The technical term "unit" used in this disclosure is intended to represent a corresponding one of analog circuits, digital circuits, and program modules that realize corresponding functions. " application scenarios and the corresponding functions to be realized.

[0021] All terms (including tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com