Wound battery cell and preparation method thereof, battery and electronic product

A battery cell and barrier layer technology, applied in the field of lithium batteries, can solve problems such as safety accidents, thermal runaway of lithium-ion batteries, etc., and achieve the effect of avoiding displacement and reliable coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

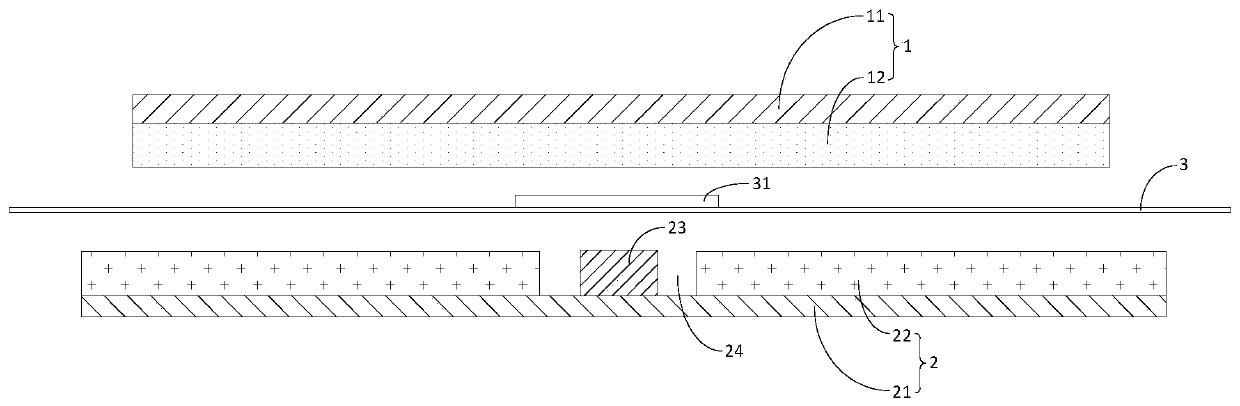

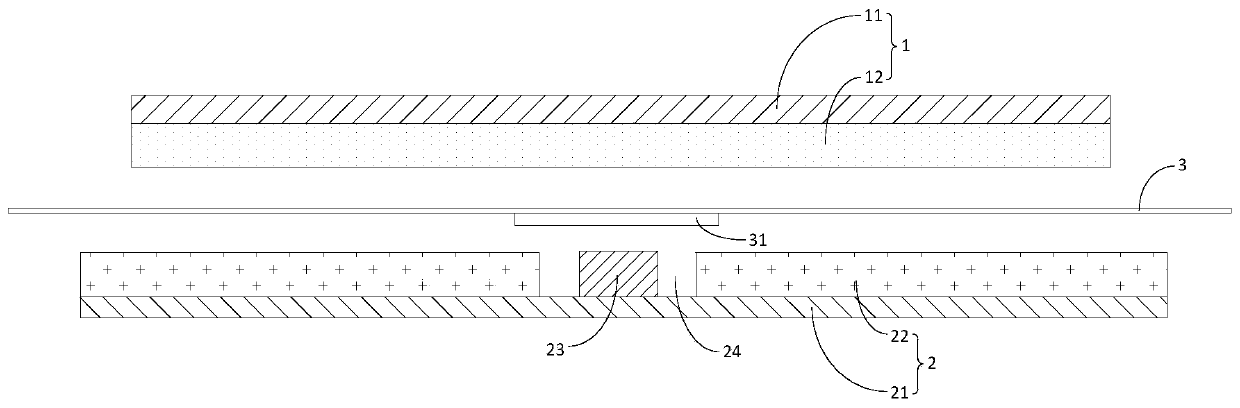

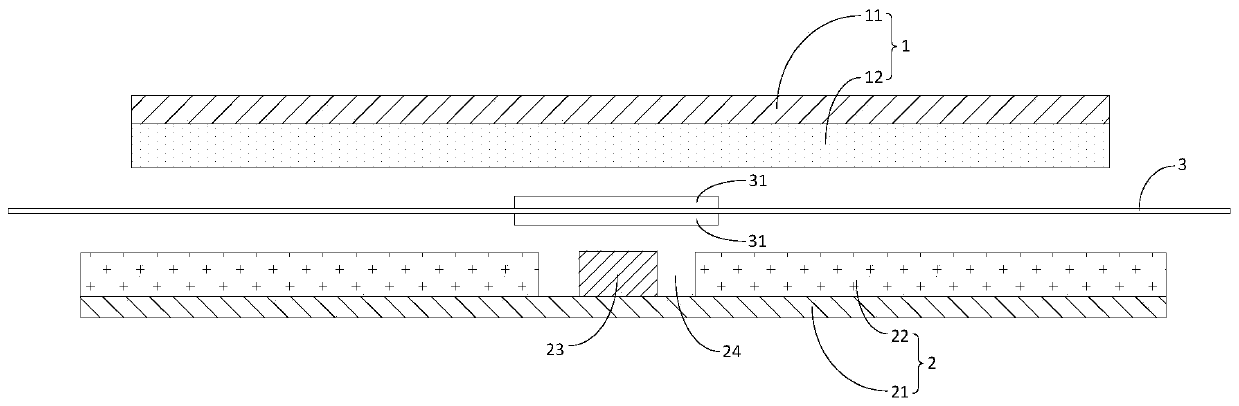

[0043] figure 1 A partial structural schematic diagram of a wound cell provided in Embodiment 1 of the present invention; figure 2 A partial structural schematic diagram of a wound cell provided in Embodiment 1 of the present invention; image 3 A partial structural schematic diagram of a wound cell provided in Embodiment 1 of the present invention; Figure 4 It is a schematic diagram of a part of the structure of the wound cell provided in Embodiment 1 of the present invention.

[0044] refer to Figure 1 to Figure 4 As shown, this embodiment provides a winding battery core, which includes a positive electrode sheet 1, a negative electrode sheet 2, and an insulating diaphragm 3 between the positive electrode sheet 1 and the negative electrode sheet 2, wherein the insulating diaphragm 3 can make The positive electrode sheet 1 and the negative electrode sheet 2 of the wound cell are insulated from each other, and the insulating diaphragm 3 has pores for lithium ions to pass...

Embodiment 2

[0078] This embodiment provides a battery, which includes a casing and a wound battery core.

[0079] The wound cell in this embodiment has the same structure as the wound cell provided in Embodiment 1, and can bring about the same or similar technical effects, so we won’t repeat them one by one here. For details, please refer to the description of the above embodiment .

Embodiment 3

[0081] This embodiment provides an electronic product, and the electronic product includes a battery.

[0082] The battery in this embodiment has the same structure as the battery provided in Embodiment 2, and can bring about the same or similar technical effects, so details will not be repeated here, and details can be referred to the descriptions of the above embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com