Drilling and grouting integrated device for treating relatively thick sediment after pile formation

A thick sediment, drilling irrigation technology, applied in the direction of drill pipe, drill pipe, sheet pile wall, etc., can solve the problems of insignificant sediment effect, large pressure loss, quality and safety hazards, etc., and achieve easy and effective sediment replacement and simple maintenance process , easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

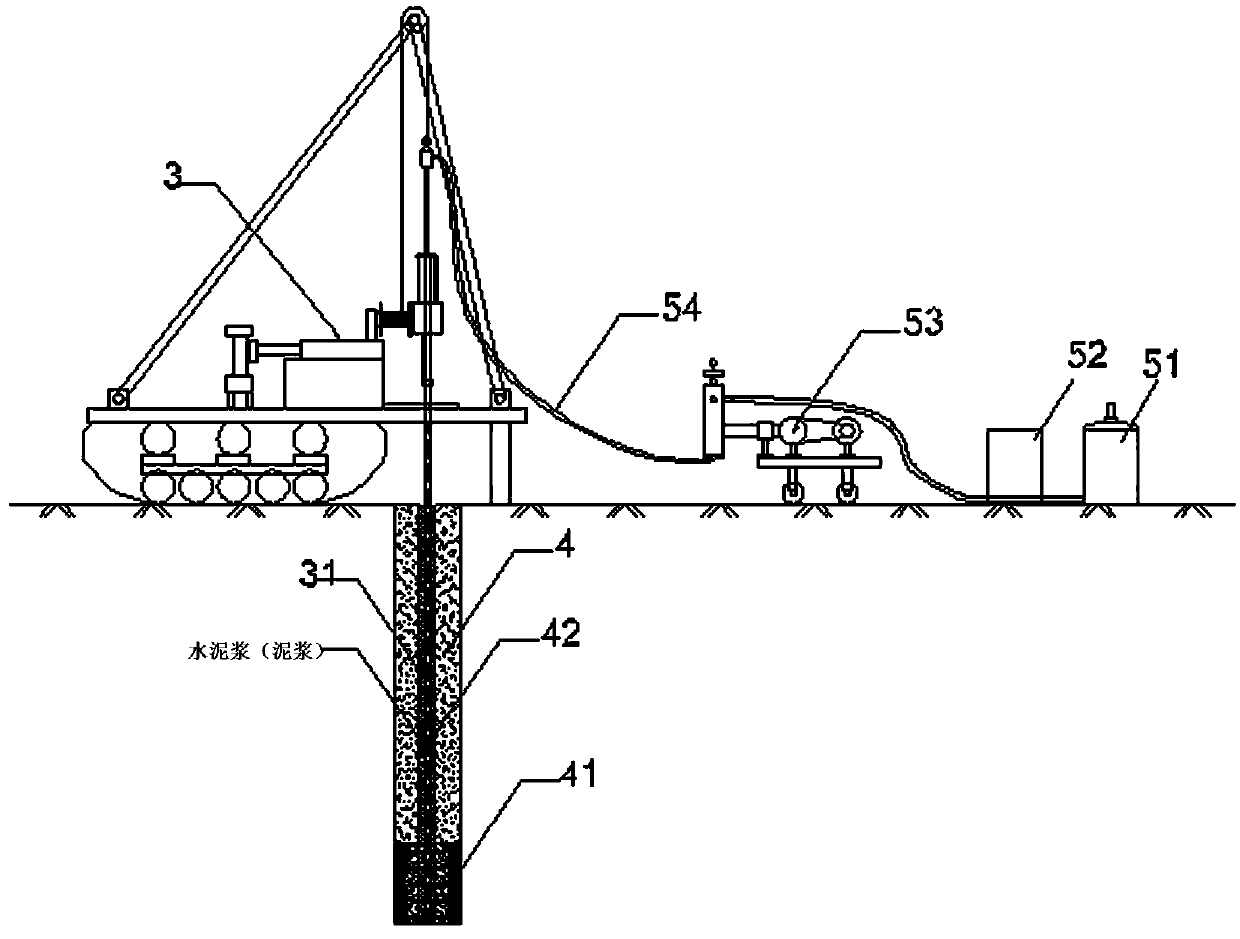

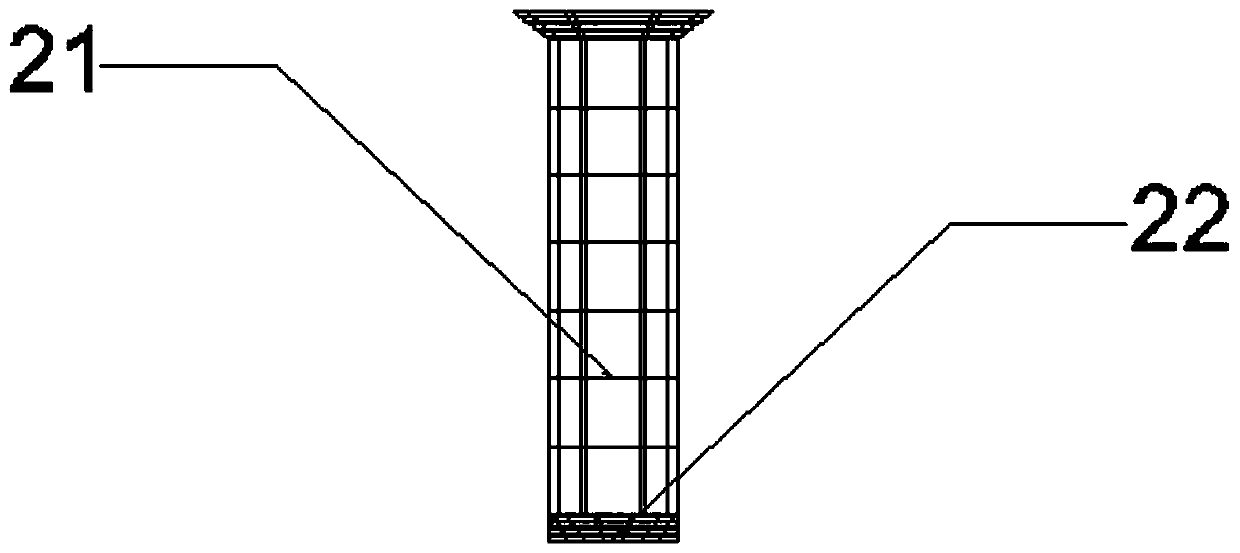

[0037] see Figure 1-12 The shown is a drilling and irrigation integrated device for processing thicker sediment after pile formation, including a hole sweeping device 1 and a grouting pipe assembly 2, the hole sweeping device 1 is arranged on the upper part of the grouting pipe assembly 2, and the hole sweeping device 1 includes an upper hole sweeping device 11 and the bottom sweeping device 12, the upper sweeping device 11 is arranged on the top of the bottom sweeping device 12,

[0038] The upper hole sweeping device 11 comprises an upper drill pipe part 111, an upper part sweep hole 112 and an upper part sweep hole steel wire rope 113, a coupling 110 is fixedly connected with the upper drill pipe part 111, and the upper part sweep holes 112 are evenly distributed on the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com