Preparation method of antibacterial polyester fiber

A polyester fiber and nanotube technology, applied in the field of textile processing, can solve problems such as poor hygroscopicity, poor air permeability, and impact on human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

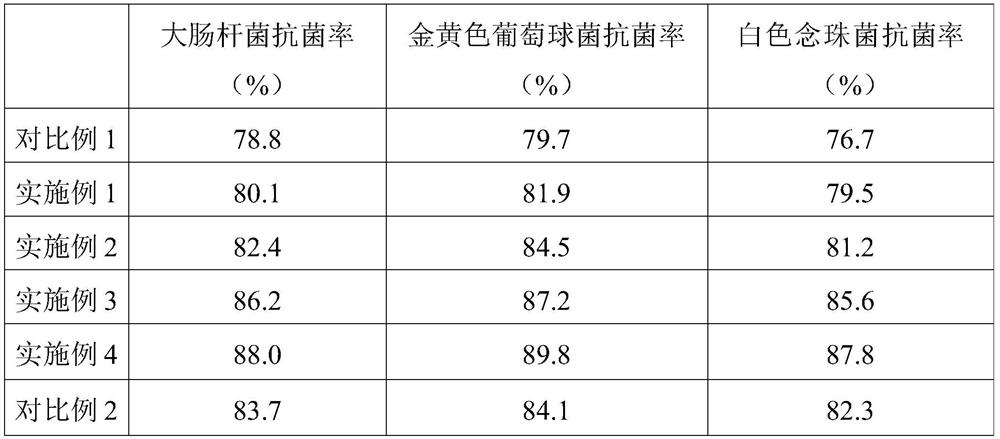

Examples

Embodiment 1

[0040] Antibacterial polyester fiber is prepared by the following method:

[0041] (1) Mix hexamethylene diisocyanate and triethylene diamine in a volume ratio of 95:5 to obtain a mixed solution. The polyester chips and the mixed solution are mixed at a solid-to-liquid ratio of 1g:8mL, soaked at 25°C for 3 hours, using 200 Filter with mesh filter cloth, mix the filter cake and deionized water at a solid-liquid ratio of 1g:8mL, soak at 25°C for 3 hours, filter, and dry the filter cake at 50°C to constant weight to obtain pretreated polyester chips;

[0042] (2) Mix 100 parts of pretreated polyester chips, 6 parts of kaolin, 6 parts of medical stone powder, 0.5 part of modified carbon nanotubes, 1 part of γ-aminopropyl triethoxysilane, and 1 part of polyethylene wax, Stir at 600 rpm for 30 minutes, and dry at 50°C for 6 hours to obtain a mixture;

[0043] (3) melting and extruding the mixture through a twin-screw extruder, spinning, winding through a spinneret to obtain primary...

Embodiment 2

[0046] Antibacterial polyester fiber is prepared by the following method:

[0047] (1) Mix hexamethylene diisocyanate and triethylene diamine in a volume ratio of 95:5 to obtain a mixed solution. The polyester chips and the mixed solution are mixed at a solid-to-liquid ratio of 1g:8mL, soaked at 25°C for 3 hours, using 200 Filter with mesh filter cloth, mix the filter cake and deionized water at a solid-liquid ratio of 1g:8mL, soak at 25°C for 3 hours, filter, and dry the filter cake at 50°C to constant weight to obtain pretreated polyester chips;

[0048] (2) Mix 100 parts of pretreated polyester chips, 6 parts of kaolin, 6 parts of medical stone powder, 0.5 part of modified carbon nanotubes, 1 part of γ-aminopropyl triethoxysilane, and 1 part of polyethylene wax, Stir at 600 rpm for 30 minutes, and dry at 50°C for 6 hours to obtain a mixture;

[0049] (3) melting and extruding the mixture through a twin-screw extruder, spinning, winding through a spinneret to obtain primary...

Embodiment 3

[0052] Antibacterial polyester fiber is prepared by the following method:

[0053] (1) Mix hexamethylene diisocyanate and triethylene diamine in a volume ratio of 95:5 to obtain a mixed solution. The polyester chips and the mixed solution are mixed at a solid-to-liquid ratio of 1g:8mL, soaked at 25°C for 3 hours, using 200 Filter with mesh filter cloth, mix the filter cake and deionized water at a solid-liquid ratio of 1g:8mL, soak at 25°C for 3 hours, filter, and dry the filter cake at 50°C to constant weight to obtain pretreated polyester chips;

[0054] (2) Mix 100 parts of pretreated polyester chips, 6 parts of kaolin, 6 parts of medical stone powder, 0.5 part of modified carbon nanotubes, 1 part of γ-aminopropyl triethoxysilane, and 1 part of polyethylene wax, Stir at 600 rpm for 30 minutes, and dry at 50°C for 6 hours to obtain a mixture;

[0055] (3) melting and extruding the mixture through a twin-screw extruder, spinning, winding through a spinneret to obtain primary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com