Preparation method and application of high-transmittance yellowing-resistant plastic coating

A plastic coating and anti-yellowing technology, which is applied in the field of coatings, can solve the problems of restricting the development prospects of engineering plastics, easy yellowing, light transmission, poor adhesion, etc., and achieve high degassing efficiency, good system compatibility, The effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

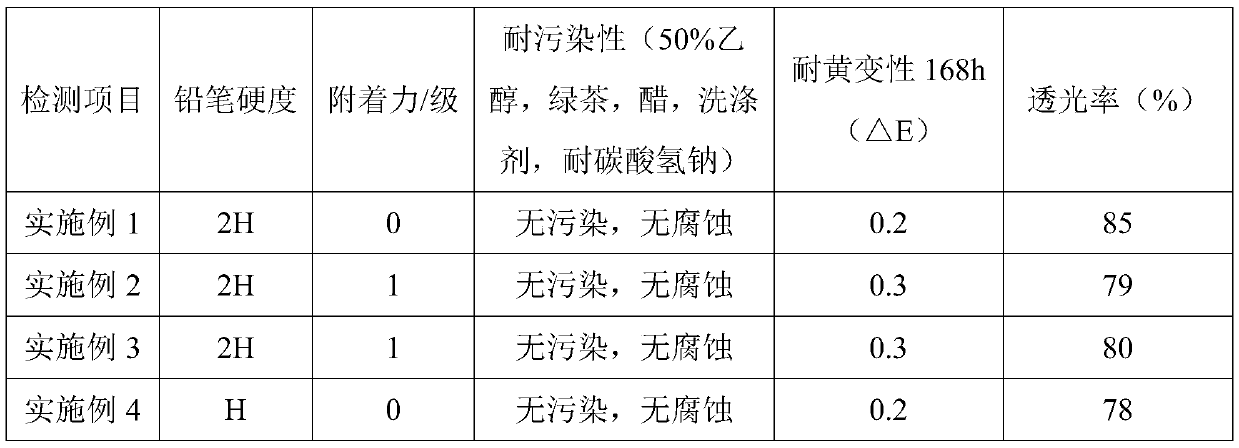

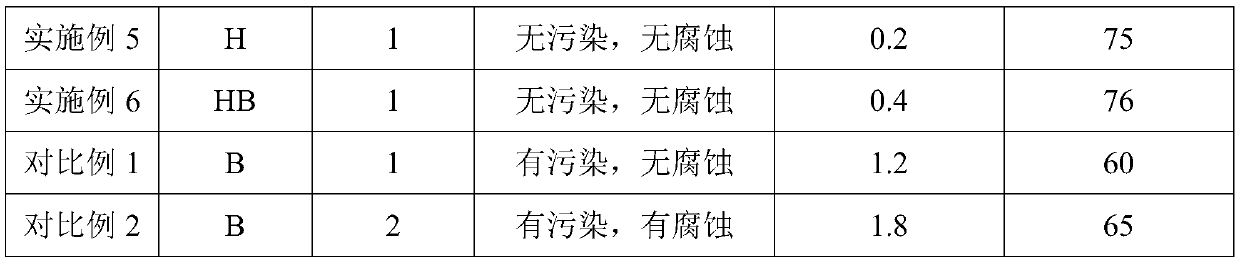

Examples

Embodiment 1

[0035] This embodiment provides a kind of high hardness, anti-yellowing plastic coating, and this coating preparation method comprises the following steps:

[0036] The first step: Weigh the wetting agent, defoamer, rheology additive, pH regulator, and deionized water according to the above weight parts; first, stir and disperse the above dispersant, defoamer and deionized water to obtain the Liquid; add rheology additive and pH adjuster to above-mentioned dispersion liquid to disperse;

[0037] The second step: weigh according to the above parts by weight: cyclopentasiloxane modified water-based polyurethane emulsion, water-based acrylic acid modified polyurethane emulsion, film-forming aid, defoamer, thickener, and the above-mentioned cyclopentasiloxane Pentadimethylsiloxane-modified water-based polyurethane emulsion and water-based acrylic acid-modified polyurethane emulsion are mixed to obtain a mixed emulsion; the above-mentioned wetting agents are sequentially added to t...

Embodiment 2

[0047] This embodiment provides a kind of high hardness, anti-yellowing plastic coating, and this coating preparation method comprises the following steps:

[0048] details as follows:

[0049] Step 1: Weigh 0.5 g of defoaming agent, 0.5 g of rheology additive, and 0.3 g of pH regulator, and take 15 g of deionized water for later use. Among them, the main component of the wetting agent is a mixture of hydrocarbon nonionic surfactants, specifically, commercially available BYK TEGO Wet 270 can be used; the commercially available TEGO AIRASE 4500 can be used as the defoamer, and its main component is mineral Oil-modified polyether ester; the rheological additive is a silicon dioxide-modified castor oil derivative, specifically commercially available TEGO AIRASE COK84; the pH regulator is an amine pH-adjusting dispersant containing 20% water, and the specific The commercially available WACKER SILRES BS198 can be used; deionized water conductivity is 20μS / cm (25°C). Select a su...

Embodiment 3

[0055] This embodiment provides a kind of high hardness, anti-yellowing plastic coating, and this coating preparation method comprises the following steps:

[0056] details as follows:

[0057] Step 1: Weigh 0.7g of defoamer, 0.2g of rheology additive, and 0.4g of pH regulator, and take 14g of deionized water for later use. Among them, the main component of the wetting agent is a mixture of hydrocarbon nonionic surfactants, specifically, commercially available BYK TEGO Wet 270 can be used; the commercially available TEGO AIRASE 4500 can be used as the defoamer, and its main component is mineral Oil-modified polyether ester; the rheological additive is a silicon dioxide-modified castor oil derivative, specifically commercially available TEGO AIRASE COK84; the pH regulator is an amine pH-adjusting dispersant containing 20% water, and the specific The commercially available WACKER SILRES BS198 can be used; deionized water conductivity is 20μS / cm (25°C). Select a suitable disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com