Self-repairing water-based polymer composite coating agent, and preparation method and application thereof

A water-based polymer, self-healing technology, applied in polyamide coatings, chemical instruments and methods, polyurea/polyurethane coatings, etc., can solve the problems of irritation, unfavorable practical application, poor mechanical strength of materials, etc. Large-scale production and use, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention discloses a preparation method of a self-repairing water-based polymer composite coating agent, the process steps of which are as follows:

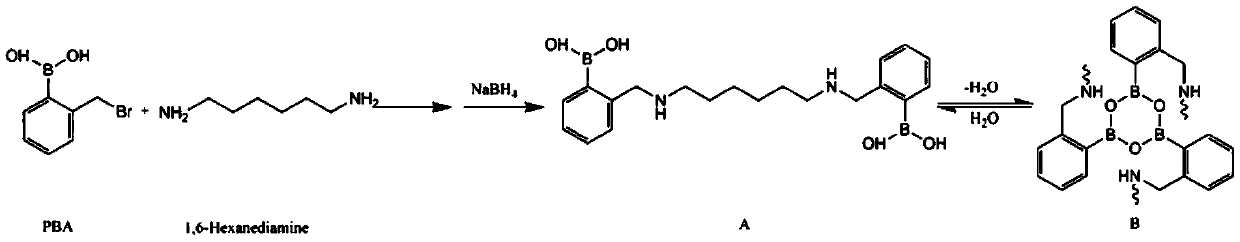

[0034] 1) Preparation of nitrogen-containing coordination borate bond compound (B)

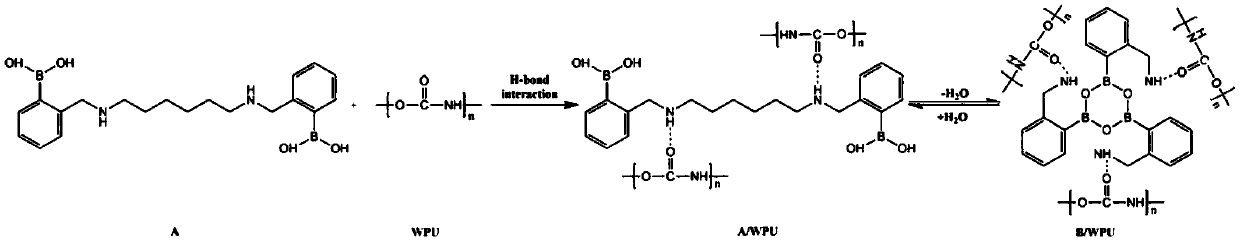

[0035] First, take 0.1-10 parts of phenylboronic acid and disperse them in 20-90 parts of alcohol solution, then take 0.5-50 parts of compounds with primary amino groups and disperse them in 20-90 parts of deionized water. Next, under mechanical stirring, the above two solutions were mixed, and stirred and reacted at 20-100° C. for 4-6 hours. Next, place the above mixed solution in an ice-water bath and slowly add 0.1 to 1 part of NaBH 4 , Continue to react for 2-3 hours. After completion of the reaction, the alcohol solution was removed by distillation to obtain a boronic acid bond-containing compound (A). Finally, drying treatment is carried out, and A is gradually dehydrated and trimerized and cross-linked to form a nitrogen-con...

Embodiment 1

[0051] (1) First, take 0.1 part of 2-bromomethylphenylboronic acid and disperse it in 20 parts of methanol, then take 0.5 part of poly(propylene glycol) bis(2-aminopropyl ether) and disperse it in 20 parts of deionized water. Next, under mechanical stirring, the above two solutions were mixed, and stirred and reacted at 30° C. for 4 h. Next, place the above mixture in an ice-water bath and slowly add 0.1 parts of NaBH 4 , continue to react for 2h. After completion of the reaction, methanol was distilled off to obtain a compound (A) containing a boronic acid bond. Finally, drying treatment is carried out, and A is gradually dehydrated and trimerized and cross-linked to form a compound (B) containing a nitrogen-coordinated borate bond.

[0052] (2) Weigh 60 parts of WPU (solid content: 50%) and place on a magnetic stirrer. Then take 1.5 parts of B, disperse it in 5 parts of ethanol, add it dropwise to WPU under the condition of stirring, continue stirring for 1 hour after the...

Embodiment 2

[0055] (1) First, take 3 parts of 2-bromomethylphenylboronic acid and disperse them in 30 parts of methanol, then take 15 parts of hexamethylenediamine and disperse them in 30 parts of deionized water. Next, under mechanical stirring, the above two solutions were mixed, and stirred and reacted at 20° C. for 4 h. Next, place the above mixed solution in an ice-water bath and slowly add 0.3 parts of NaBH 4 , Continue to react for 3h. After completion of the reaction, methanol was distilled off to obtain a compound (A) containing a boronic acid bond. Finally, drying treatment is carried out, and A is gradually dehydrated and trimerized and cross-linked to form a compound (B) containing a nitrogen-coordinated borate bond.

[0056] (2) Weigh 90 parts of WPU (solid content: 60%) and place on a magnetic stirrer. Then take 3.78 parts of B, disperse it in 10 parts of ethanol, add it dropwise to WPU under the condition of stirring, continue stirring for 1 hour after dropping, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com