Plant fiber firework pipeline and firework base and preparation method thereof

A technology of plant fibers and fireworks, which is applied in the fields of plant fiber fireworks pipes and fireworks bases and their preparation, can solve problems such as unclear division of labor in processing steps, unfavorable product quality, and difficulty in decomposition, so as to avoid pollution, reduce environmental pollution, increase The effect of soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

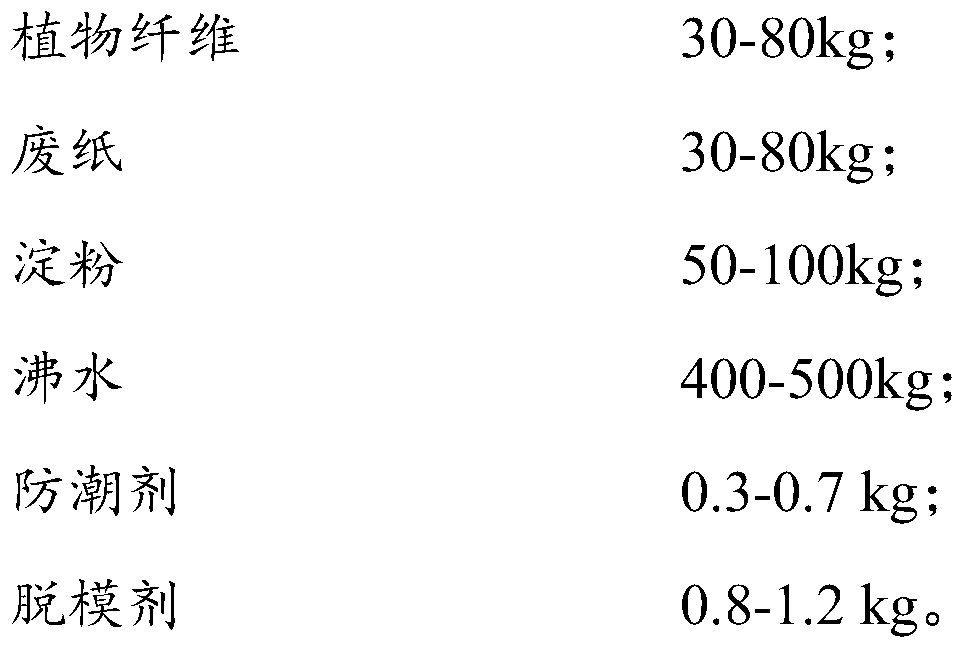

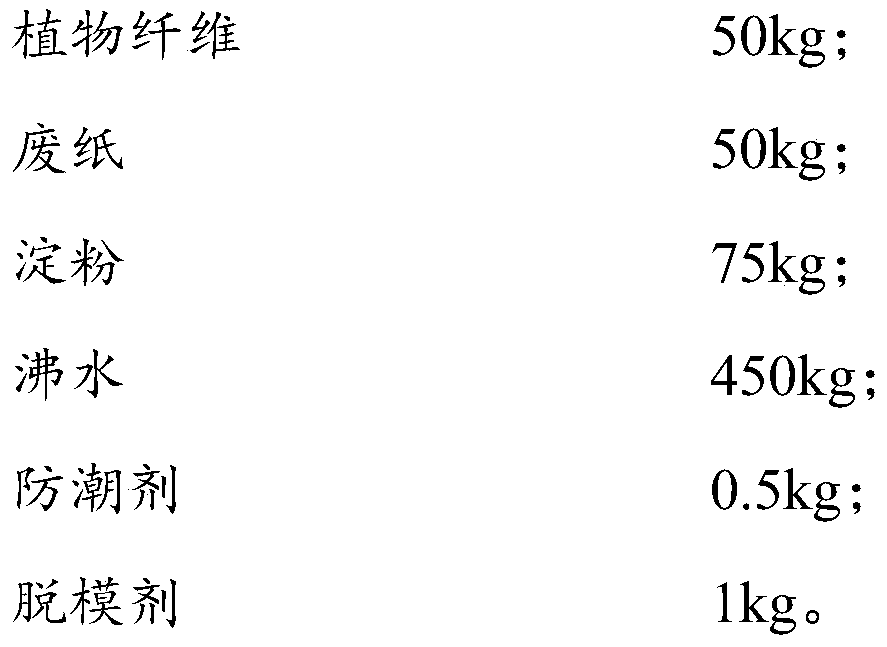

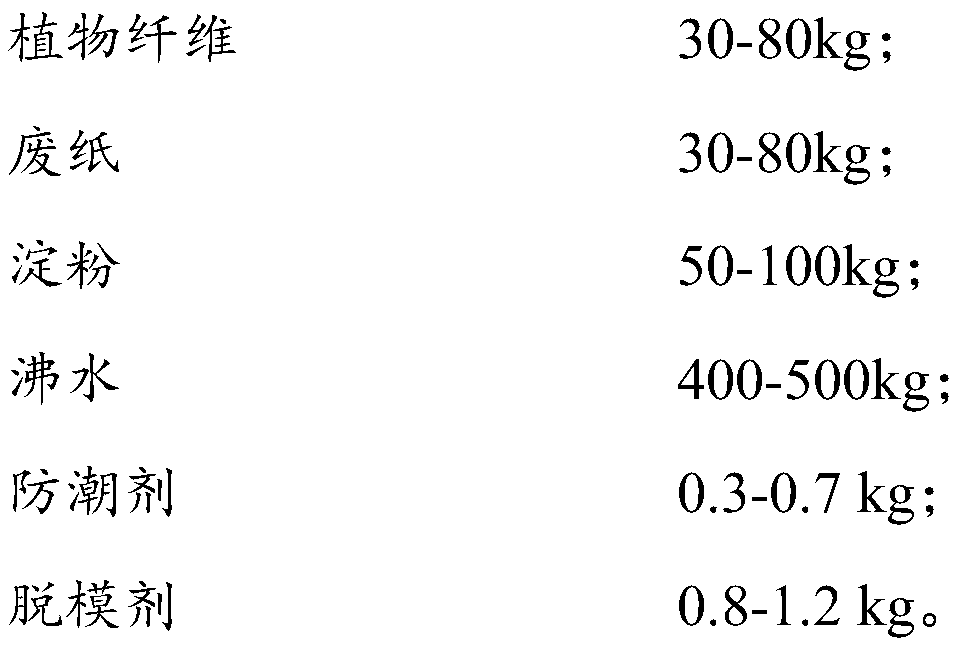

[0022] Embodiment 1: Get 50kg of plant fiber; 50kg of waste paper; 75kg of starch; 450kg of boiling water; 0.5kg of moisture-proof agent; , and then add 75kg of starch, 0.5kg of moisture-proof agent, 1kg of release agent, and 1.7kg of toughening agent, and stir until it is in the form of a paste for later use;

[0023] (2) Molding: Pour the prepared paste into the molding cavity, compress and seal the mold with a hydraulic press, the raw material expands and foams in the cavity, the molding temperature is 270°C, the molding time is 400 seconds, and then the demoulding is carried out. The plant fiber fireworks pipe and fireworks base are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com