Mine filling cementing material as well as preparation method and application thereof

A technology of mine filling and cementing materials, which is applied in the direction of filling, mining equipment, earth square drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

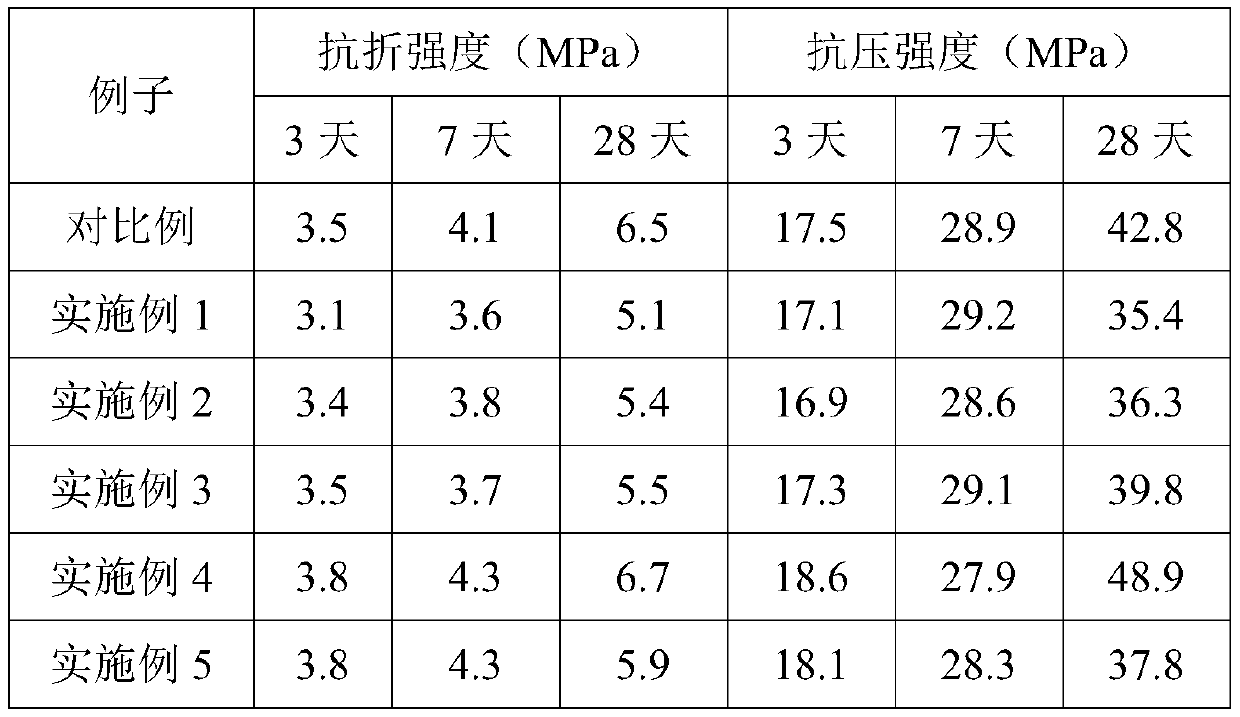

Examples

Embodiment 1

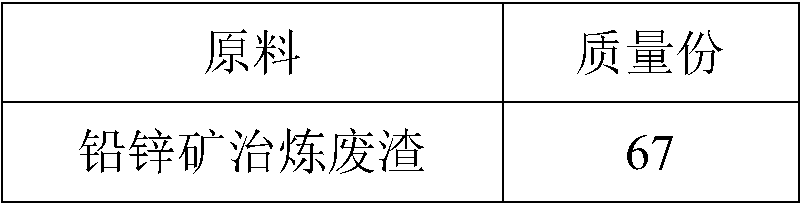

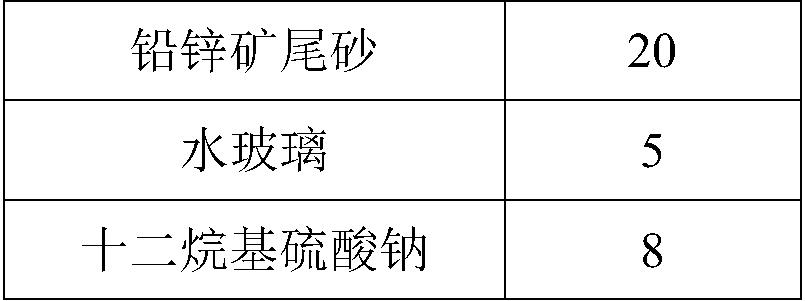

[0036] The composition of the mine filling cementing material in this example is shown in Table 1.

[0037] Table 1 Example 1 Mine filling cementing material composition

[0038] raw material parts by mass Lead-zinc ore smelting waste residue 60 Lead-zinc mine tailings 20 water glass 8 Sodium dodecyl sulfate 12

Embodiment 2

[0040] The composition of the mine filling cementing material in this example is shown in Table 2.

[0041] Table 2 Example 2 Mine filling cementing material composition

[0042] raw material parts by mass Lead-zinc ore smelting waste residue 70 Lead-zinc mine tailings 10 water glass 12 Sodium dodecyl sulfate 8

Embodiment 3

[0044] The components of the mine filling cementing material in this example are shown in Table 3.

[0045] Table 3 Example 3 Mine filling cement material composition

[0046] raw material parts by mass Lead-zinc ore smelting waste residue 65 Lead-zinc mine tailings 18 water glass 7 Sodium dodecyl sulfate 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com