Pressure balancing tank capable of realizing online cleaning and sterilization

A technology for cleaning, disinfecting, and balancing tanks, which is applied in the field of pressure balancing tanks, which can solve the problems of high hidden dangers in drug quality and safety, difficult to detect, and product contamination, and achieve the effects of avoiding hidden dangers in drug quality and safety, convenient pressure adjustment, and reducing re-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

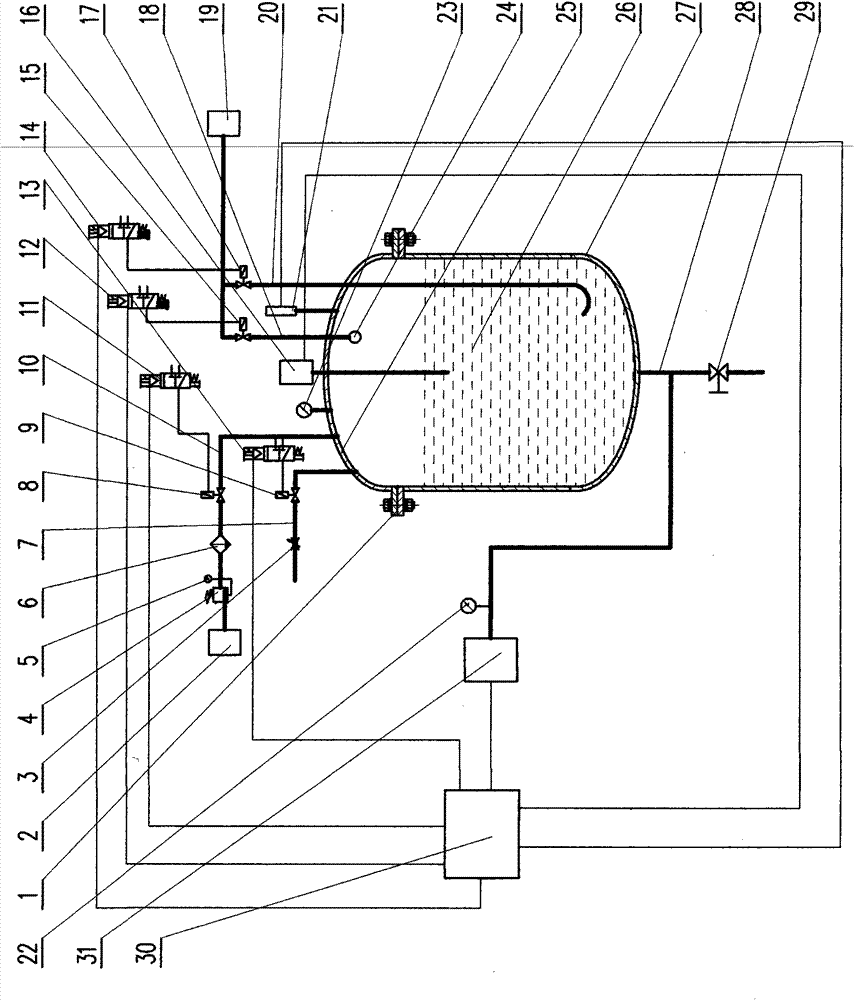

[0016] This embodiment is composed of tank body 27, tank cover 25, liquid medicine input assembly, pressure balance assembly, liquid outlet pipe 28, pressure sensor 21, pressure gauge 23, liquid level gauge 16 and data receiving and processing device 30 and online cleaning and disinfection Input component composition.

[0017] The edge of the end face of the tank body 27 and the tank cover 25 is provided with a flange 1, and the two are connected into a closed container through the flange 1 (with a sealing ring therebetween), and the pressure sensor 21, the pressure gauge 23 and the liquid level gauge The contact of 16 stretches in the inner cavity of this closed container by tank cover 25, and liquid outlet pipe 28 communicates with the lower end of this closed container inner cavity.

[0018] The liquid medicine input assembly includes the liquid medicine input pipe 20, the liquid medicine input valve 17 (can adopt the valve that accords with sanitary conditions, and can be ...

Embodiment 2

[0029] This embodiment is composed of tank body 27, tank cover 25, liquid medicine input assembly, pressure balance assembly, liquid outlet pipe 28, pressure sensor 21, pressure gauge 23, liquid level gauge 16 and data receiving and processing device 30 and online cleaning and disinfection Input component composition. The input valves used in this example are valves that meet sanitary conditions and cannot be automatically opened and closed, such as pneumatic diaphragm valves, etc. Therefore, they all need to be matched with corresponding control solenoid valves to implement linkage. At this time, the gas and liquid valves Combined with the control solenoid valve, it is equivalent to the "gas and liquid valve" in the first embodiment, and its data control line is connected to the control solenoid valve, as follows:

[0030] The edge of the end face of the tank body 27 and the tank cover 25 is provided with a flange 1, and the two are connected into a closed container through t...

Embodiment 3

[0042]This embodiment is basically the same as Embodiment 1, the difference is that the gas discharge valve 9 in the decompression device adopts a proportional adjustment electric diaphragm valve, since the valve can control the opening diameter of the valve according to the data of the system, the control is more precise, Therefore, the throttle valve 3 is canceled, and the output end of the gas discharge valve 9 is no longer connected to the discharge port via the throttle valve 3, but is directly connected to the discharge port.

[0043] Its use process is identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com