Method for granulating medicament for treating osteoporosis

An osteoporosis and drug technology, which is applied in the field of granulation of drugs for the treatment of osteoporosis, can solve the problems of poor granule fluidity, difficulty in filling, and low bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

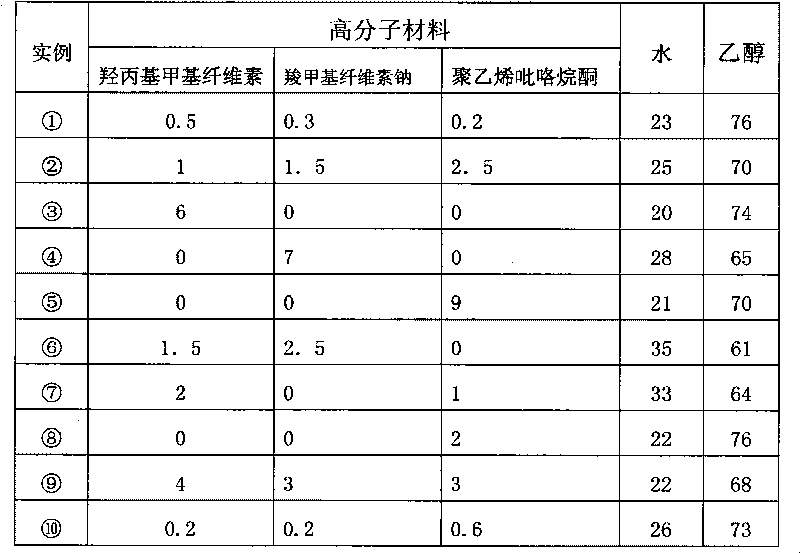

Embodiment 1

[0033] Mix the drug material and auxiliary materials in a wet mixing granulator for 3 minutes to obtain a mixed drug material; take 1 part by weight of hydroxypropyl methylcellulose, 1.5 parts by weight of sodium carboxymethyl cellulose, and 2.5 parts by weight of polyvinylpyrrolidone, add water 25 parts by weight and 70 parts by weight of ethanol are prepared into a polymer mixed material containing 75% alcohol, and 1 part by weight of the polymer mixed material is added according to the ratio of 6 to 8 parts by weight of the mixed drug material, and stirred for 1 minute to obtain a soft Use the rocking granulation machine to wet the granules, pour the prepared wet granules into the boiling dryer, set the main air temperature to 80-90°C when the medicinal material is drying, and set the temperature of the auxiliary air duct to about 70°C, and control the temperature of the medicinal material to 60°C. ~70 DEG C, the time is about 25 minutes, the granules are dried and discharge...

Embodiment 2

[0035] The drug material and the auxiliary material are mixed in a wet mixing granulator for 3 minutes to obtain a mixed drug material; take 6 parts by weight of hydroxypropyl methylcellulose, add 20 parts by weight of water, and 74 parts by weight of ethanol, and prepare a drug containing about 68% alcohol. For the polymer mixed material, add 1 part by weight of the polymer mixed material in a ratio of 6 to 8 parts by weight of the mixed drug material, stir for 1 minute to obtain a soft material, use a swinging granulator to wet the granules, and prepare the wet granules Pour it into the boiling dryer, set the main air temperature to 80-90°C when the drug material is drying, and the auxiliary air duct temperature to about 70°C, control the temperature of the drug material to 65-75°C for about 25 minutes, and discharge the granules after drying. Then use a 24-mesh sieve to granulate, mix, and pack into No. 1 capsules at 0.45 g / grain to obtain capsule medicine.

Embodiment 3

[0037] The drug material and the auxiliary material are mixed in a wet mixing granulator for 3 minutes to obtain a mixed drug material; take 1.5 parts by weight of hydroxypropyl methylcellulose, 2.5 parts by weight of sodium carboxymethyl cellulose, add 35 parts by weight of water, and 61 parts by weight of ethanol 1 part, be mixed with the macromolecule mixed material containing about 65% of alcohol, add 1 weight part of described polymer mixed material in the ratio of 7 weight parts of mixed medicine material, stir 1 minute and make soft material, wet with rocking type granulator Granules, pour the prepared wet granules into the boiling dryer, set the temperature of the main air to 80-90°C and the temperature of the auxiliary air duct to about 70°C when drying the medicinal material, and control the temperature of the medicinal material to 62-72°C for about 25 minutes , discharging after the granules are dried, the granules are sized with a 24-mesh sieve, mixed, packed into N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com