Bypass flow type biological phosphorus removal process

A biological phosphorus removal and process technology, which is applied in the direction of biological sludge treatment, biological water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of low carbon-phosphorus ratio of influent, increased operating cost, and increased operating cost carbon footprint and other issues, to achieve the effect of promoting denitrification, reducing costs, and improving the performance and stability of nitrogen and phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

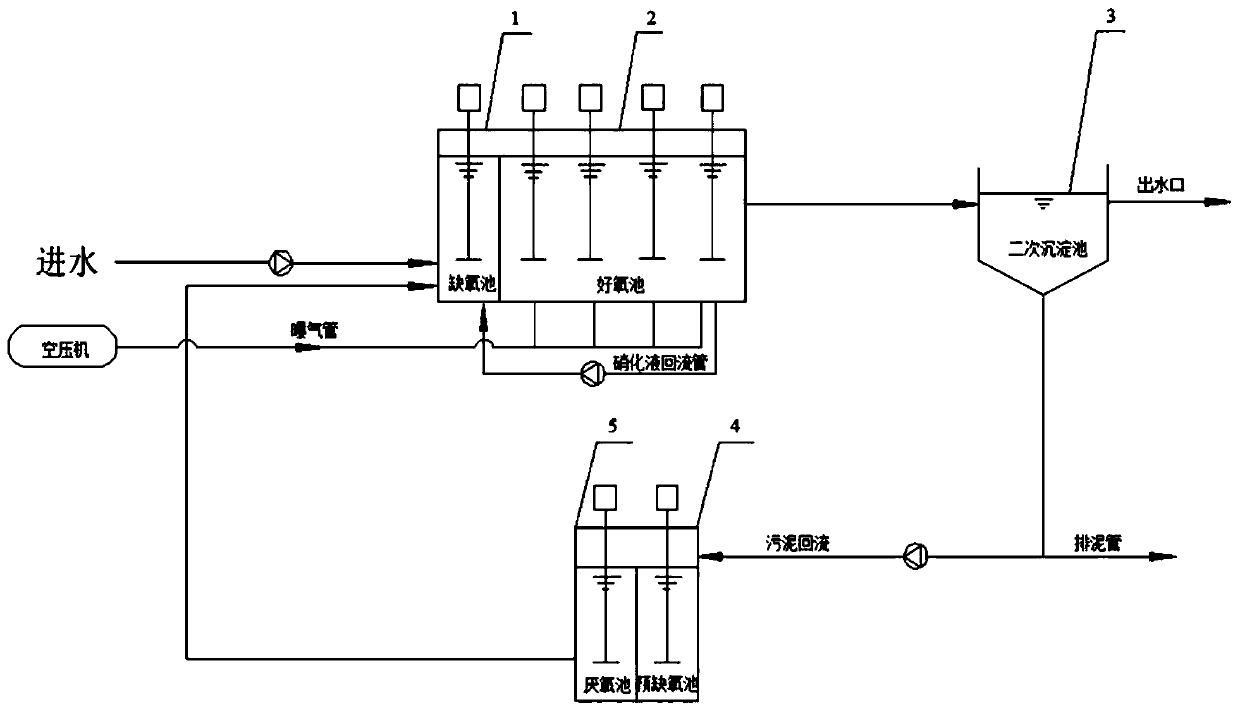

[0029] A side-flow biological phosphorus removal process, comprising a primary sedimentation tank, anoxic tank, an aerobic tank, a side-flow pre-anoxic tank, a side-flow anaerobic tank and a secondary sedimentation tank; comprising the following steps:

[0030] Step 1: Introduce the sewage into the anoxic pool, and flow into the aerobic pool through the anoxic pool;

[0031] Step 2: Return part of the nitrified sludge water discharged from the aerobic tank to the anoxic tank, and the other part of the nitrified sludge water is introduced into the secondary sedimentation tank;

[0032] Step 3: After the nitrifying liquid sludge water in the secondary settling tank is separated from the mud and water, the supernatant is discharged directly to the treatment system as effluent or after advanced treatment. The sludge is divided into two parts, part of which is discharged outside and part of which is discharged as residual sludge The treatment system realizes biological phosphorus r...

Embodiment 2

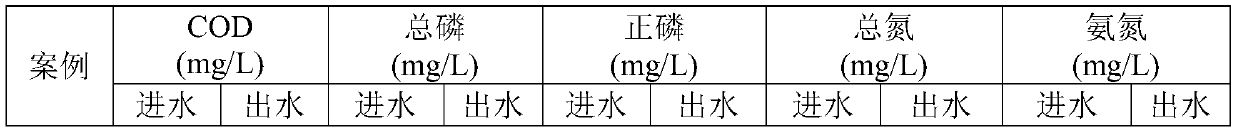

[0051]Take the sludge from the return section of a sewage treatment plant, after cleaning and domestication, the process of using this process is as follows:

[0052] Step 1: The water temperature of the anoxic pool where the raw sewage enters the mainstream is 23°C, the HRT of the anoxic pool is 2.7h, and the sludge concentration is 3200mg / L;

[0053] Step 2: The aerobic pool receives the mud-water mixture discharged from the anoxic pool. The HRT of the aerobic pool is 10.7h, the DO is greater than 2.0mg / L, and the reflux ratio of the nitrifying liquid is 300%;

[0054] Step 3: The mud-water mixture discharged from the aerobic tank enters the secondary sedimentation tank for mud-water separation. The sedimentation time of the secondary sedimentation tank is 2.7 hours, and the sludge concentration is 7800mg / L;

[0055] Step 4: After the mud-water separation in the secondary settling tank, the supernatant is directly discharged from the system; the settled sludge after passing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com