Torpedo ladle master station control system and concrete distribution system as well as distribution method

A master station control and torpedo tank technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of wasted labor cost, inconvenient operation, low degree of automation, etc., to improve distribution efficiency and achieve intelligent , the effect of easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

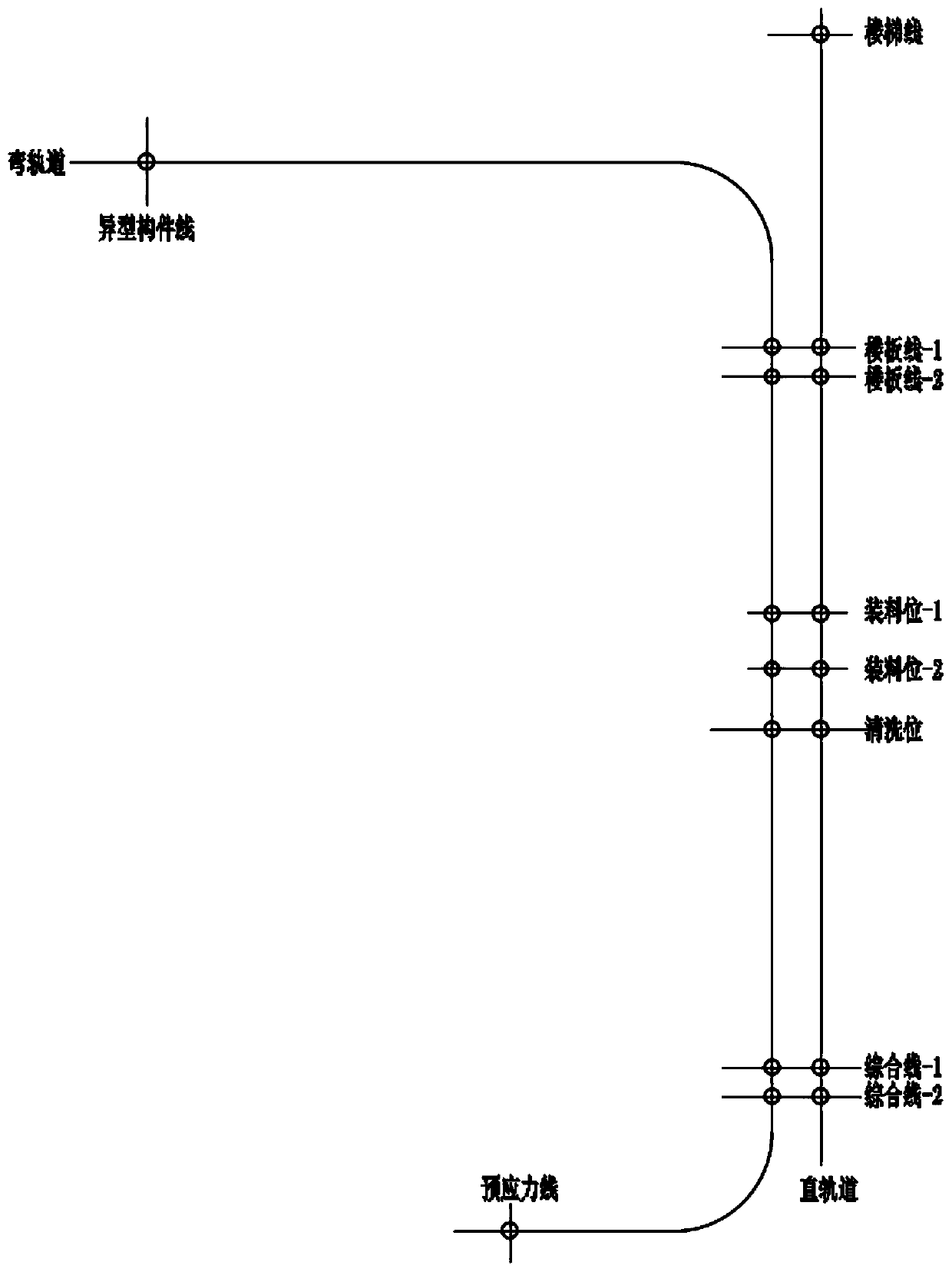

[0040] Such as figure 1As shown, the torpedo tank master station control system is mainly used in prefabricated PC intelligent factories. There are 7 call points on the line. 2 conveying tracks (one curved track, one straight track), 2 torpedo tank cars are arranged on each track, a total of 4 torpedo tank cars. 2 tracks and 4 torpedo tanks need to cover a total of 5 production lines including special-shaped component lines, prestressed lines, stair lines, floor lines, and comprehensive lines. Both the floor line and the comprehensive line have 2 call points, and the remaining 3 production lines have 1 call point for each production line, a total of 7 call points. There are 2 hosts in the mixing station, and each host adopts an inclined chute to span 2 tracks; each track has 2 loading positions, a total of 4; each track has a cleaning position.

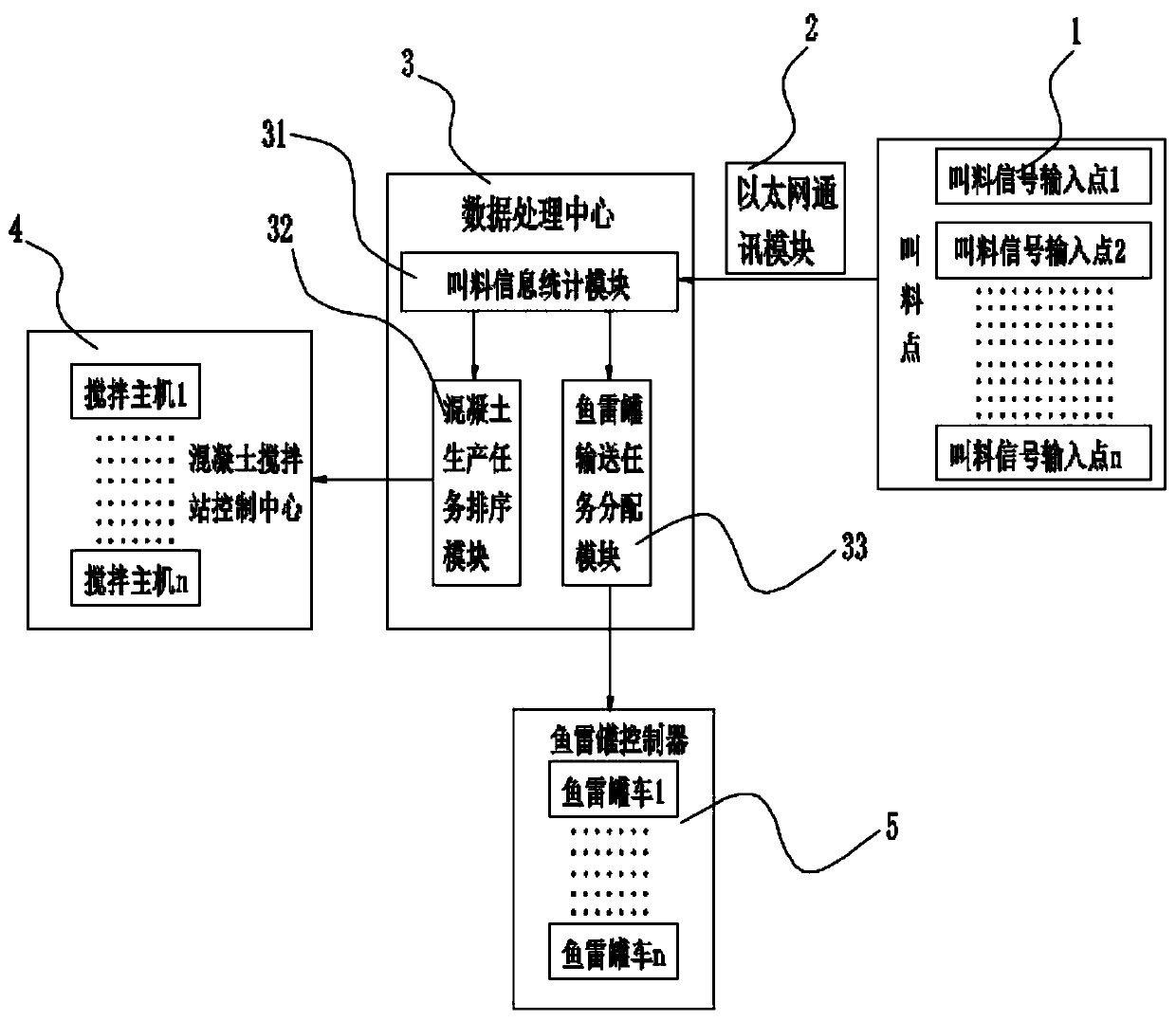

[0041] Such as figure 2 Shown, the torpedo tank main station control system among the present invention comprises data processi...

Embodiment 2

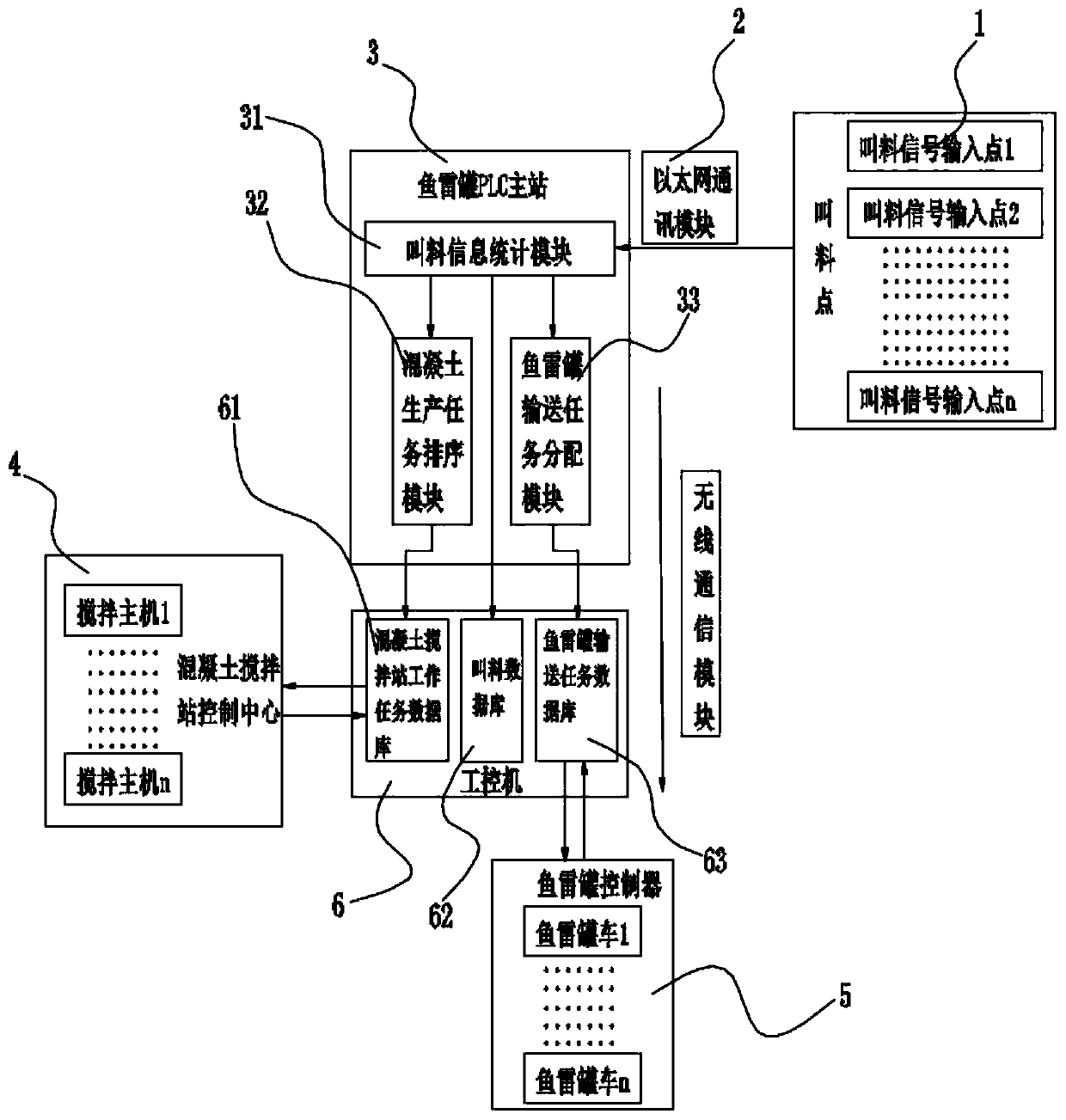

[0046] Such as Figures 3 to 6 As shown, a concrete distribution system also includes the above-mentioned torpedo tank master station control system, the signal output end of the torpedo tank master station control system is connected with the torpedo tank controller 5 in the torpedo tank master station and the concrete in the concrete mixing station respectively. The mixing station control center 4 performs information interaction respectively.

[0047] More preferably, it also includes an industrial computer 6, which is provided with a concrete mixing station task database 61, a call database 62 and a torpedo tank delivery task database 63;

[0048] The signal output end of the concrete production task sorting module 32 in the control system of the torpedo tank master station is connected to the signal input end of the concrete mixing plant task database 61, and the signal output end of the concrete mixing plant task database 61 is connected to the concrete mixing plant cont...

Embodiment 3

[0062] A concrete distribution method, applied to the above-mentioned concrete distribution system, comprising the steps of:

[0063] The control system of the main station of the torpedo tank receives the call information, the working information of the concrete mixing host and the delivery information of the torpedo tank;

[0064] According to the priority level of each production line, the control system of the torpedo tank master station selects the concrete mixing host that can perform the mixing task in combination with the work information of the main machine of the concrete mixing station. The control system of the torpedo tank master station Conveying information and assigning outlets;

[0065] The control system of the torpedo tank master station selects the torpedo tank that can perform the transportation task according to the delivery information of the discharge port and the torpedo tank.

[0066] Further, the call information is input from the call signal input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com