A two-degree-of-freedom folding and unfolding three-dimensional micromanipulator with a three-stage amplifying mechanism

A three-stage amplification and micro-manipulator technology, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as limiting the application range of micro-manipulation robots, increasing the difficulty of manipulator motion control, and single-degree-of-freedom micro-manipulators no longer adapting. , to achieve the effect of improving static and dynamic characteristics, compact structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

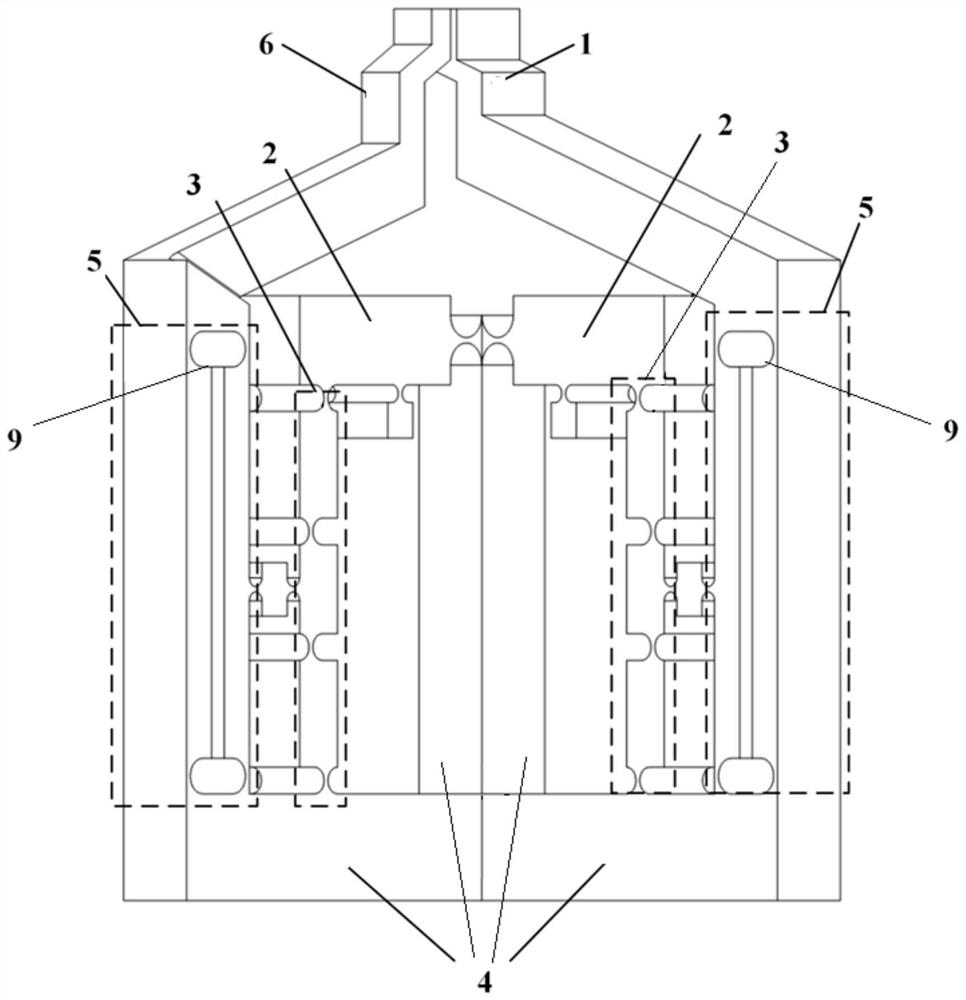

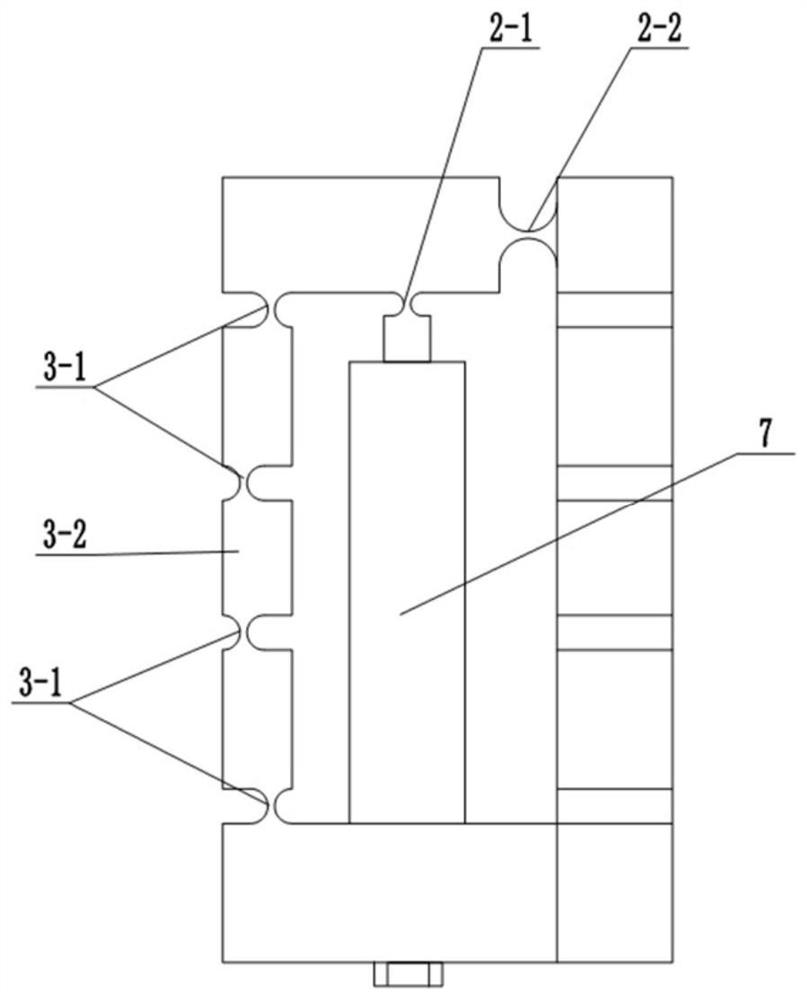

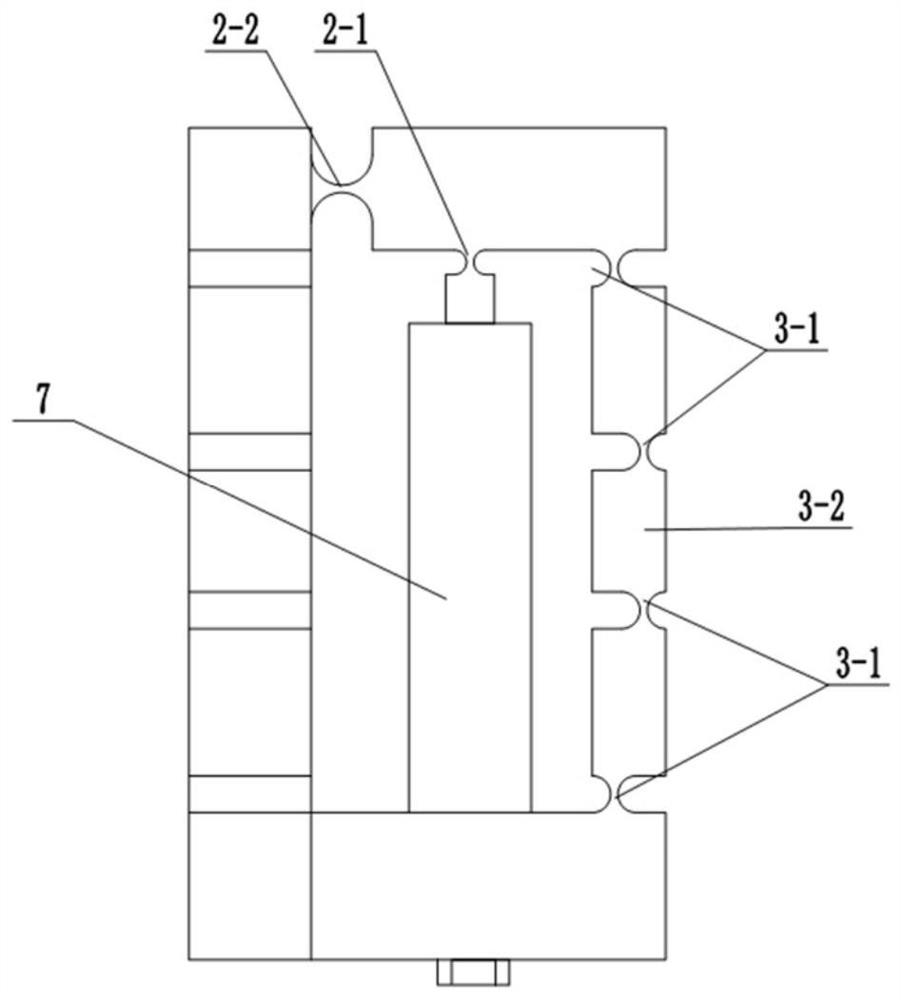

[0023] see Figure 1 to Figure 3 , a two-degree-of-freedom folding and unfolding three-dimensional micro-manipulator with a three-stage amplifying mechanism. The body structure of the micro-manipulator is integrally formed by sheet metal wire cutting, including two identical three-stage amplifying mechanisms and two clamping jaws, two three-stage The amplifying mechanism is folded along the symmetry axis, and the two planes are at an angle of 90°. Each three-stage amplifying mechanism includes a lever displacement amplifying mechanism I2, a half-bridge displacement amplifying mechanism 3, a lever displacement amplifying mechanism II5, a parallelogram guide mechanism 9 and a base b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com