A wellhead loading and unloading method for intelligent elevators in mechanized workover operations

An elevator and intelligent technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of hidden safety hazards, high labor intensity, etc., and achieve the effect of improving operating efficiency, reducing labor intensity, and reducing the number of hydraulic channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

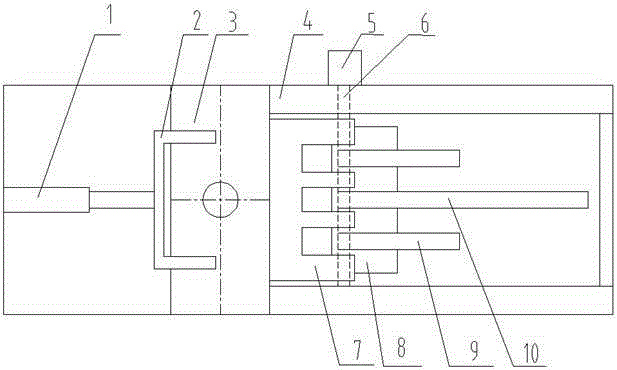

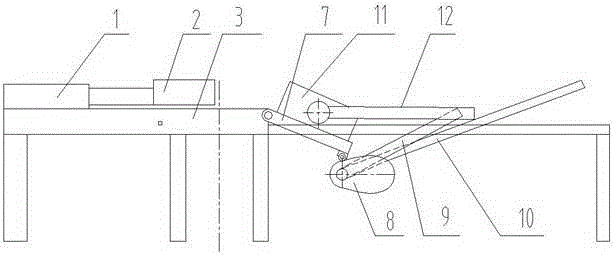

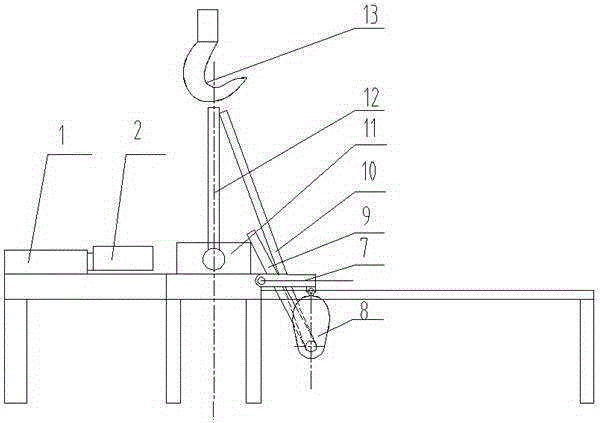

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0021] Such as Figure 1-3 As shown, the wellhead platform 3 is connected to the support 4, wherein the height of the support 4 is slightly lower than the height of the wellhead platform 3. A connecting plate 7 is connected between the wellhead platform 3 and the support 4 . A hydraulic motor 5 is installed on one side of the wellhead platform, and the hydraulic motor 5 is connected with the central shaft 6 and can drive it to rotate. Different positions on the central axis are respectively equipped with a cam 8, an elevator installation arm 9 and an eyelet pushing arm 10. Cam 8 is in contact with the roller at the lower end of connecting plate 7, and the height of connecting plate 7 can be adjusted when the cam ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com