Raw material pre-sieving device for concrete preparation for civil engineering

A pre-raw material and civil engineering technology, applied in the direction of automatic disconnection emergency protection device, circuit device, emergency protection circuit device, etc., can solve the problems of low work efficiency, time-consuming and laborious, etc., and achieve convenient operation, reduce noise, reduce The effect of complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

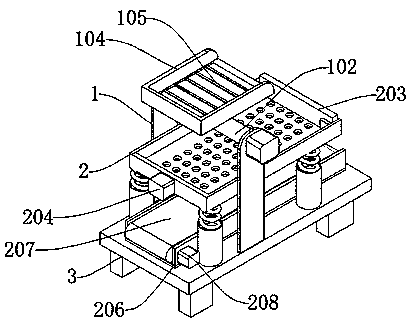

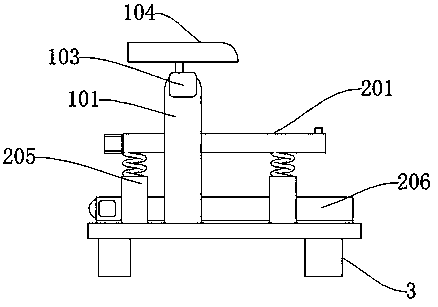

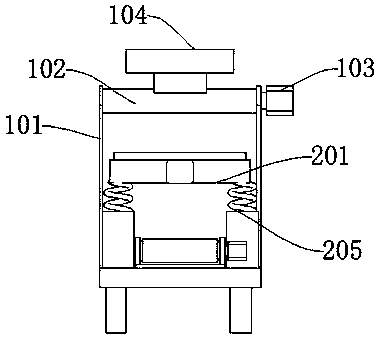

[0032] Such as Figure 1-Figure 10As shown, the present invention provides a technical solution: a pre-raw material screening device prepared by concrete for civil engineering, including a base 3, a screening mechanism 2 is arranged above the base 3, and a feeding mechanism 1 is arranged above the screening mechanism 2, Feeding mechanism 1 comprises vertical plate 101, rotating column 102, No. 1 motor 103, and vertical plate 101 inner side is provided with rotating column 102, and vertical plate 101 front portion is provided with No. 1 motor 103, and rotating column 102 is provided with feeding plate 104, and feeding plate 104 is provided with non-slip rubber pad 105; described sieving mechanism 2 comprises sieve plate 201, stopper 202, baffle plate 203, and sieve plate 201 is provided with stopper 202, and stopper 202 inner side is provided with baffle plate 203, A vibration motor 204 is installed on the side of the sieve plate 201, a spring 205 is arranged on the lower end o...

Embodiment 2

[0036] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the sieving mechanism 2 includes a sieve plate 201, a stopper 202, and a baffle 203, the sieve plate 201 is provided with a stopper 202, and the inner side of the stopper 202 is provided with a stopper Plate 203, a slide table 209 is provided below the sieve plate 201, a slide rail 210 is arranged on the slide table 209, and an electric telescopic column 211 is installed on the side of the slide table 209.

[0037] The vibrating motor 204 drives the sieve plate 201 to vibrate on the spring 205 to sieve the raw materials, and replaces it with an electric telescopic column 211 to drive the slide table 209 to reciprocate rapidly on the slide rail 210, so that the sieve plate 201 moves continuously, and the Raw materials are screened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com