Efficient antibacterial mask

A mask and high-efficiency technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of inability to kill harmful microorganisms, short service life of masks, environmental pollution, etc., to achieve good protection, prolong service life, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

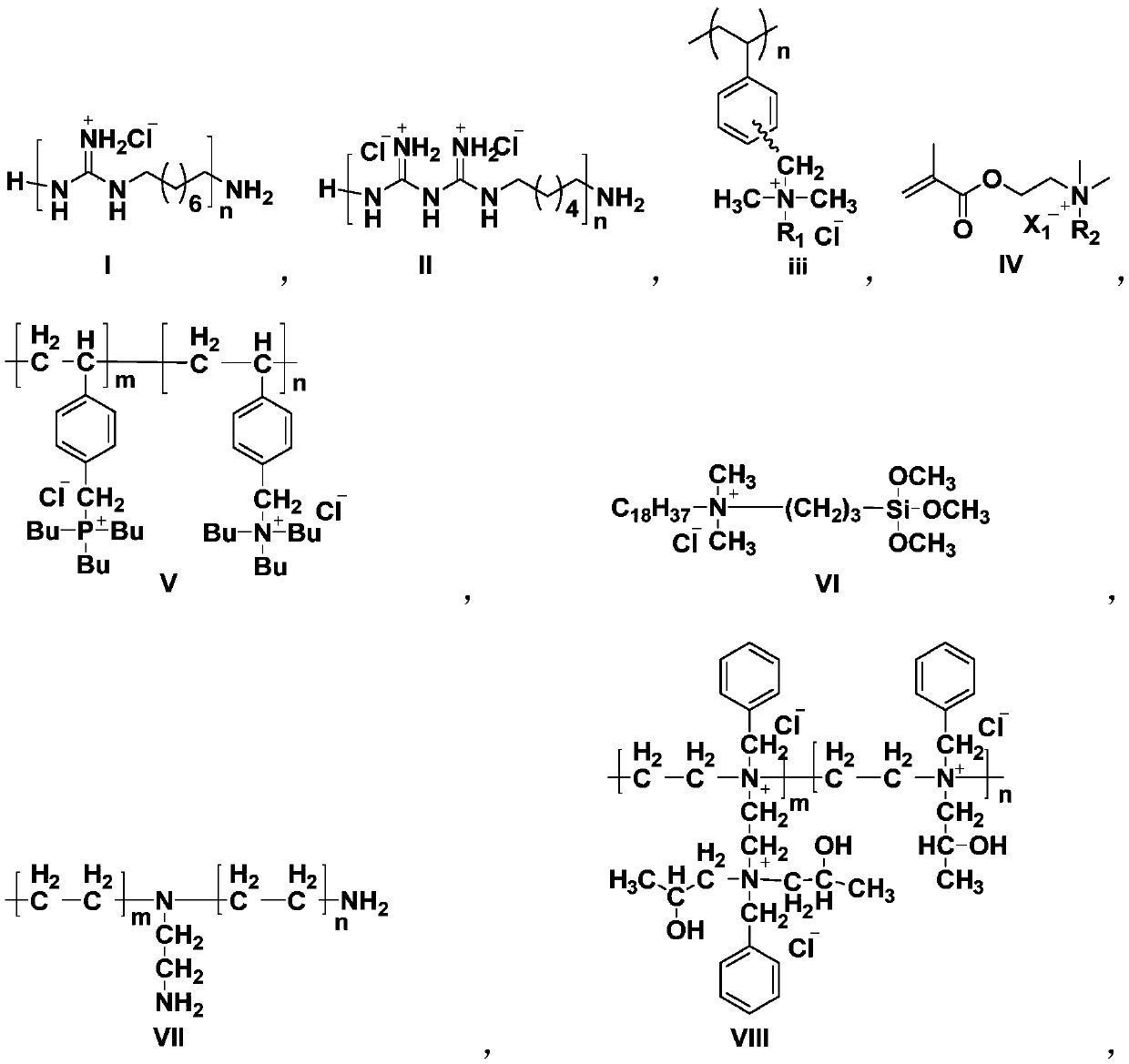

Method used

Image

Examples

preparation example Construction

[0048] In one embodiment, the preparation method of the bactericidal layer comprises the steps of:

[0049] Dissolving the bactericidal material in a solvent to obtain a bactericidal solution;

[0050] The non-woven fabric, woven fabric or polymer film is coated (such as spin-coated), sprayed or soaked with the bactericidal solution, and then dried.

[0051] Further in one embodiment, the solvent may be selected from but limited to at least one of methanol, ethanol, isopropanol and water.

[0052] Further in one embodiment, in the bactericidal solution, the mass concentration of the bactericidal material is 0.01-5 wt%, for example, 1 wt%.

[0053] In one embodiment, both the inner non-woven fabric layer and the outer non-woven fabric layer are made of at least one of polypropylene, polyester fiber, polyamide, polyacrylonitrile and polyvinyl chloride fiber Non-woven layer.

[0054] In one embodiment, the polyvinyl fluoride film can be made of polytetrafluoroethylene, a copol...

Embodiment 1

[0056] Embodiment 1 copolymer P1-1 (R 3 =H,X 2 - = Cl - ) preparation

[0057] According to reaction formula (1-1), Specifically include steps: 116g (1mol) N 1 ,N 1 ,N 2 ,N 2 -Tetramethyl-1,2-ethylenediamine (A-1), 112g (1mol) 1,4-vinylpiperazine (A-2), 66g (0.5mol) 1,2-bis(dimethylamino ) ethanol (A-3), 146g (0.5mol) ethylenediaminetetraacetic acid (A-4-1) and 1L dichloroethyl ether (A-5-1) mixed with 500mL water, stirred at 30°C for 30 minutes , refluxed for 8 hours, cooled, concentrated to remove the solvent, precipitated a solid with acetone, and dried under vacuum to obtain 328 g of copolymer P1-1.

Embodiment 2

[0058] Embodiment 2 copolymer P1-2 (R 3 =H,X 2 - =ClO 4 - ) preparation

[0059] According to reaction formula (1-2), The specific steps include: heating 100g of copolymer P1-1 and 200mL of perchloric acid aqueous solution to reflux, cooling and crystallizing after the reaction, washing with acetone, draining, and vacuum drying to obtain 109g of copolymer P1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com