Papaya-flavored nut milk beverage and preparation method thereof

A technology of papaya and nut milk, which is applied in the field of papaya-flavored nut milk drink and its preparation, can solve problems such as poor effect, and achieve the effects of easy absorption by the human body, rich nutrition, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

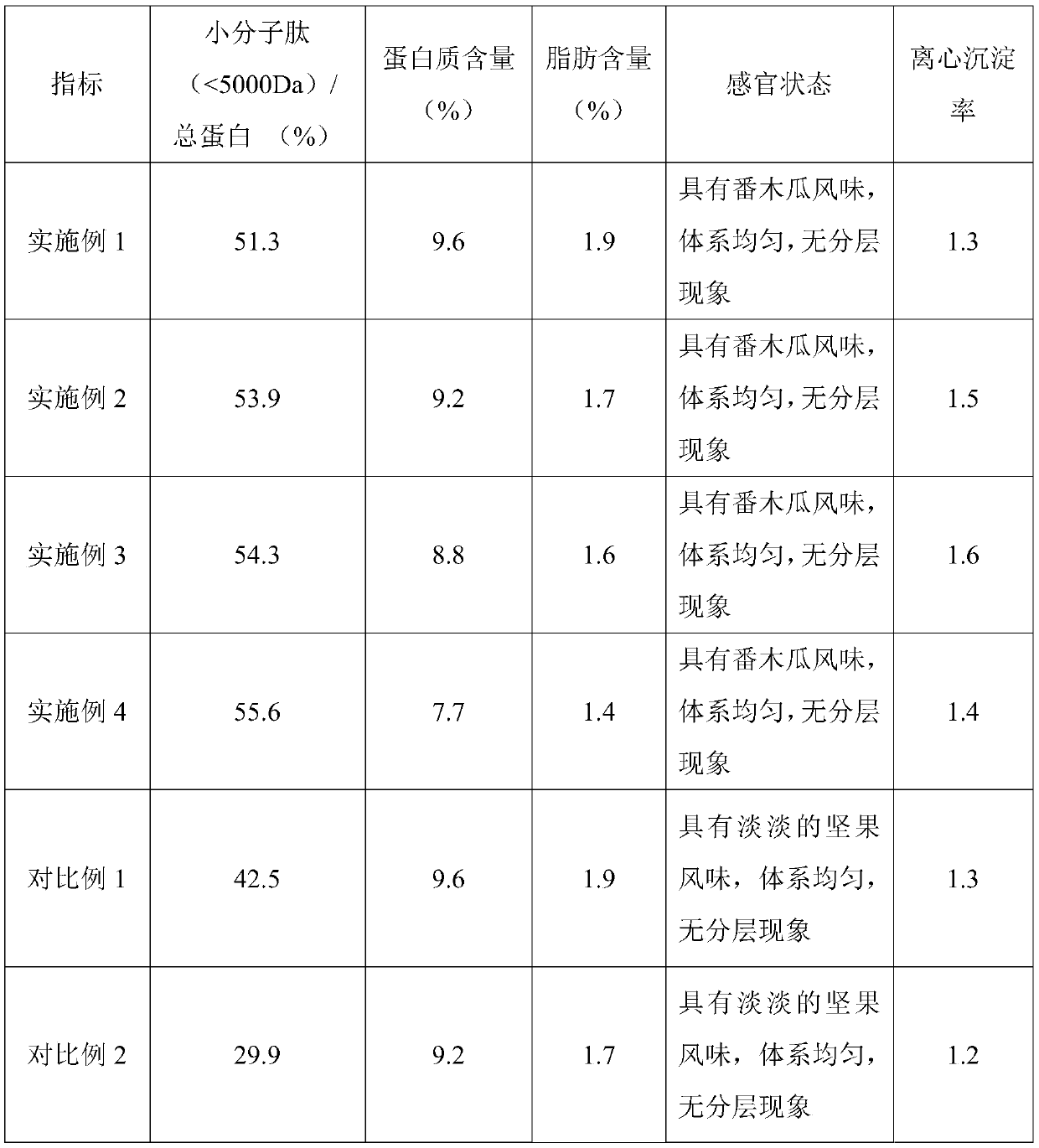

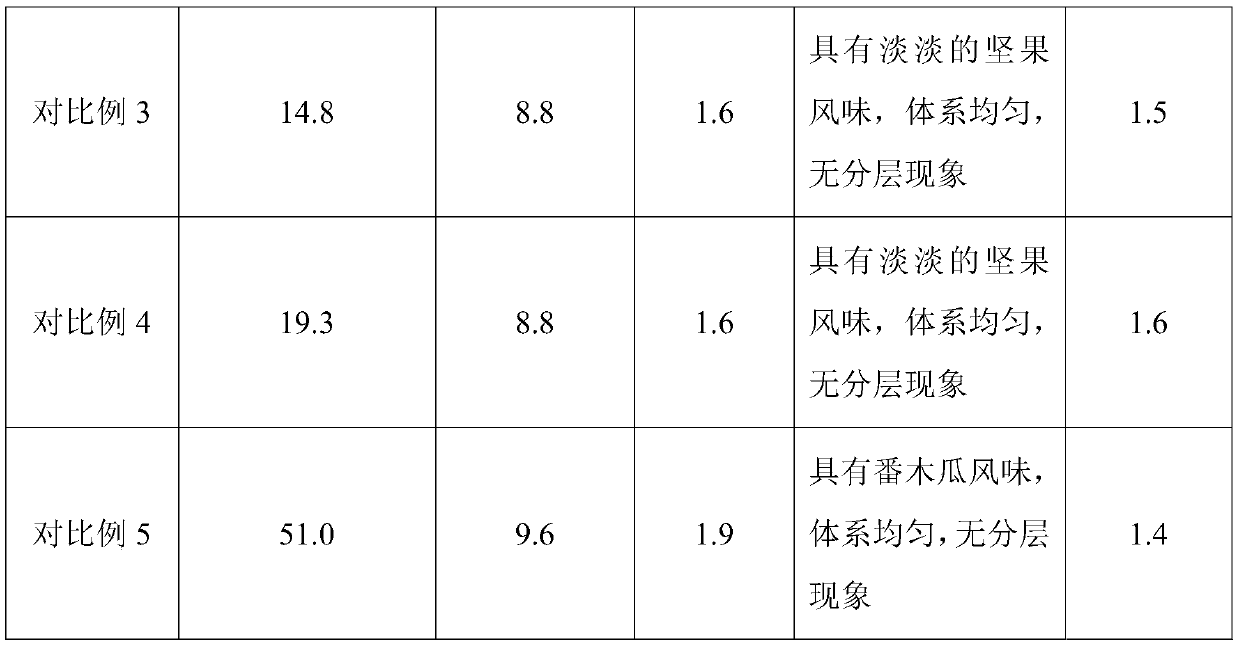

Examples

Embodiment 1

[0035] A method for preparing a papaya-flavored nut milk drink, comprising the steps of:

[0036] Take macadamia nut oil remaining by screw pressing, and the residual oil rate of fruit pulp is 5%. After being pulverized by a pulverizer, pass through an 80-mesh sieve to obtain nut pulp, and then add 7 mature fresh papaya juice produced by pressing Mix thoroughly, and then go through a homogenizer to refine and homogenize to obtain a mixed solution. The mass ratio of the nut meal and papaya juice is 1:1.5; the homogeneous mixed solution is spirally stirred in a container, and the mixed solution is heated at an ultrasonic power of 250W. Treat for 8 minutes under the same conditions, and carry out natural enzymolysis at 55°C for 5 hours; use 20KV / cm high-voltage pulse electric field to deenzyme and sterilize the enzymolysis solution for 40μs; add water to the enzymolysis solution and add sugar with a mass fraction of 5%; Under the conditions of 55°C and pressure of 25MPa, two homo...

Embodiment 2

[0038] A method for preparing a papaya-flavored nut milk drink, comprising the steps of:

[0039] Take the macadamia nut oil remaining by screw pressing, the residual oil rate of the fruit pulp is 10%, crush it with a grinder, pass through an 80-mesh sieve to get the nut meal powder, and then add 3 ripe fresh papaya juices obtained by pressing and mix thoroughly , and then homogenized by a homogenizer to obtain a mixed solution, the mass ratio of the nut meal and papaya juice is 1:3; the homogeneous mixed solution is spirally stirred in a container, and the mixed solution is heated under the condition of ultrasonic power 200W Treat at low temperature for 10 minutes, and carry out natural enzymolysis at 50°C for 5 hours; use 25KV / cm high-voltage pulsed electric field to deenzyme and sterilize the enzymolysis solution for 40μs; add water to the enzymolysis solution and add sugar with a mass fraction of 8%; Under the conditions of 55°C and pressure of 25MPa, two homogenization tr...

Embodiment 3

[0041] A method for preparing a papaya-flavored nut milk drink, comprising the steps of:

[0042] Take macadamia nut oil remaining by screw press, the residual oil rate of fruit pulp is 7%, crushed by a pulverizer and sieved through 80 mesh to get nut meal powder, then add 5 ripe fresh papaya juices obtained by pressing and mix thoroughly , and then homogenized by a homogenizer to obtain a mixed solution, the mass ratio of the nut meal and papaya juice is 1:2; the homogeneous mixed solution is spirally stirred in a container, and the mixed solution is heated under the condition of an ultrasonic power of 300W Treat at low temperature for 5 minutes, and carry out natural enzymolysis at 55°C for 4 hours; use 25KV / cm high-voltage pulsed electric field to deenzyme and sterilize the enzymolysis solution for 30μs; add water to the enzymolysis solution, and add sugar with a mass fraction of 8%; Carry out two homogenization treatments at 60°C and a pressure of 25MPa, and perform degass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com