Grain-oriented electrical steel sheet and magnetic domain refining method therefor

A technology of oriented electrical steel sheets and electrical steel sheets, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problem of magnetic flux density reduction and achieve the effect of improving iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

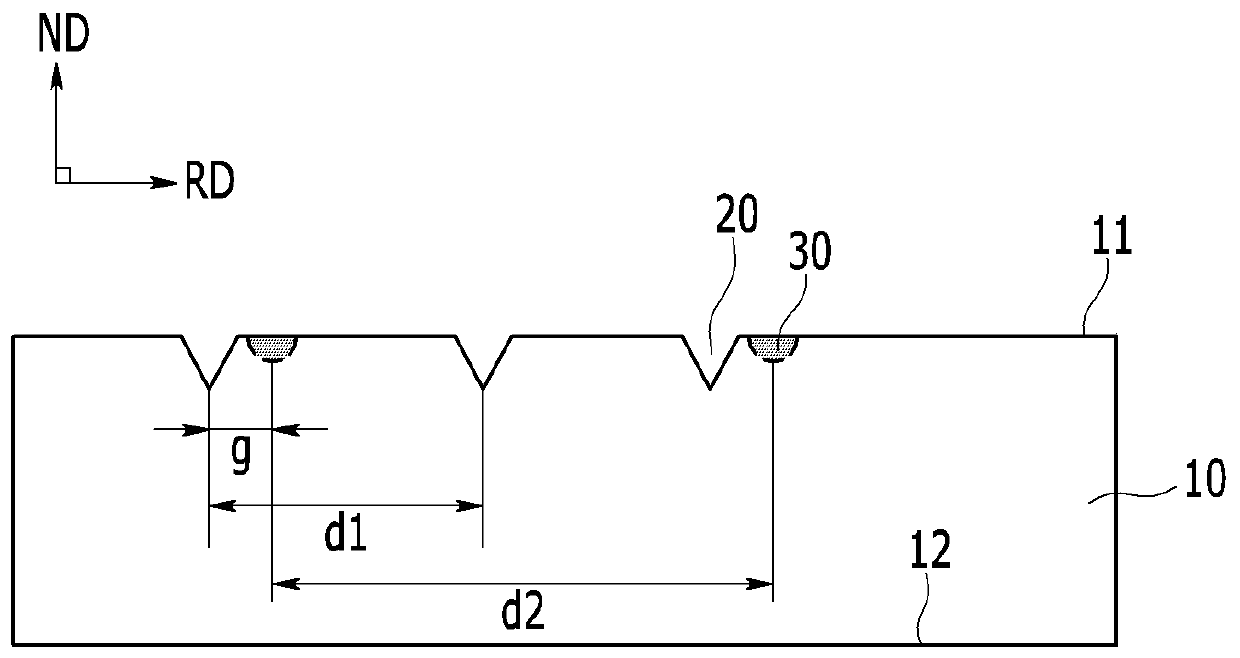

[0069] Experimental example 1: Spacing between groove and thermal shock line

[0070] A cold-rolled grain-oriented electrical steel sheet having a thickness of 0.20 mm was prepared. Grooves were formed on one surface of the electrical steel sheet by using a continuous fiber (Fiber) laser and irradiating laser light with a copper (copper) mirror. The width W of the laser beam was 50 μm, and the length L of the laser beam was 5000 μm. The energy density of the laser is 1.5J / mm 2 , the depth of the trench is 10 μm.

[0071] The pitch d1 between the trenches organized in Table 1 below formed trenches, and an insulating film was formed.

[0072]Subsequently, a continuous fiber laser is used on one or the other surface of the electrical steel sheet, and a copper mirror is used to irradiate the laser light to form thermal shock lines. The width W of the laser beam was 500 μm, and the length L of the laser beam was 10000 μm. The energy density of the laser is 0.1J / mm 2 .

[007...

experiment example 2

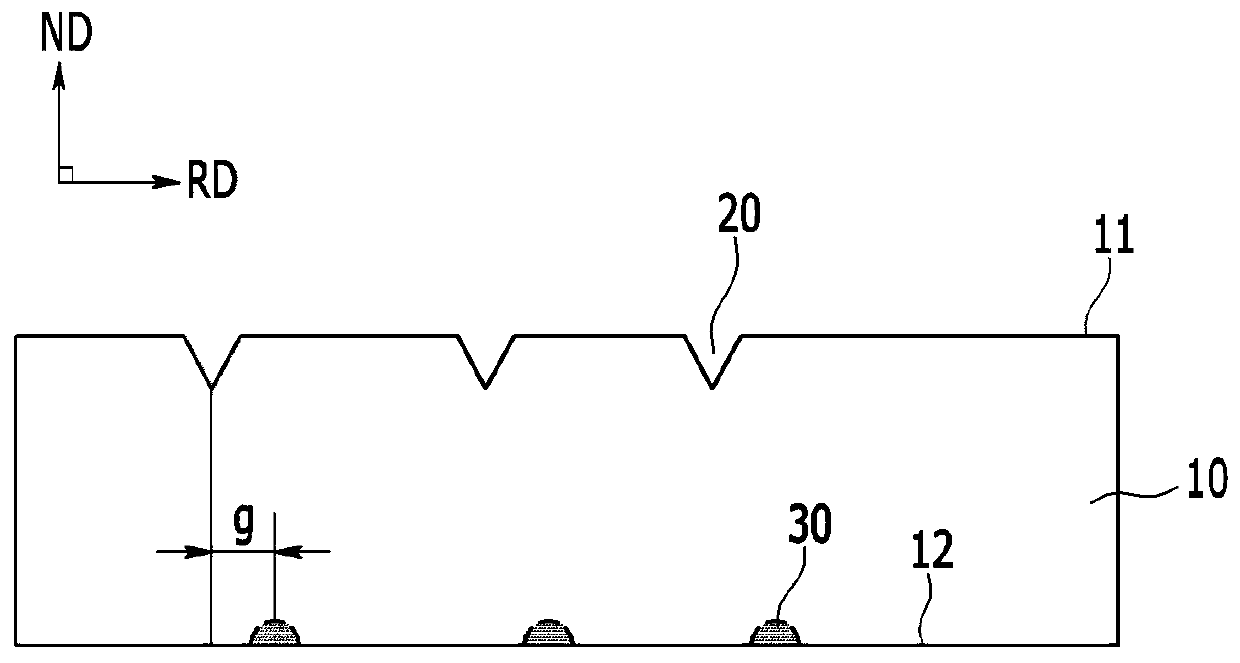

[0080] Experimental Example 2: Groove Depth

[0081] A cold-rolled grain-oriented electrical steel sheet having a thickness of 0.20 mm was prepared. Grooves are formed on one surface of an electrical steel sheet by using a continuous fiber (Fiber) laser and irradiating laser light with a copper (copper) mirror. The width W of the laser beam is 50 μm, and the length L of the laser beam is 5000 μm. The energy density of the laser light and the depth of the groove were changed to the values shown in Table 2 below, respectively.

[0082] The pitch d1 between the trenches organized in Table 2 below formed trenches, and an insulating film was formed.

[0083] The thermal shock lines are formed on one surface of the steel plate with the same spacing d2 between the thermal shock lines as the spacing d1 between the grooves described below, and the average spacing g between the grooves and the thermal shock lines is adjusted to 0.7 to 0.8 mm.

[0084] 【Table 2】

[0085]

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam width | aaaaa | aaaaa |

| beam width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com