Non-oriented electrical steel sheet and manufacturing method therefor

A technology of grain-oriented electrical steel sheet and electrical steel sheet, applied in circuits, electrical components, manufacturing tools, etc., can solve the problems of long time, decreased productivity, and insignificant application results, and achieves the promotion of surface fine grains and improvement of iron loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

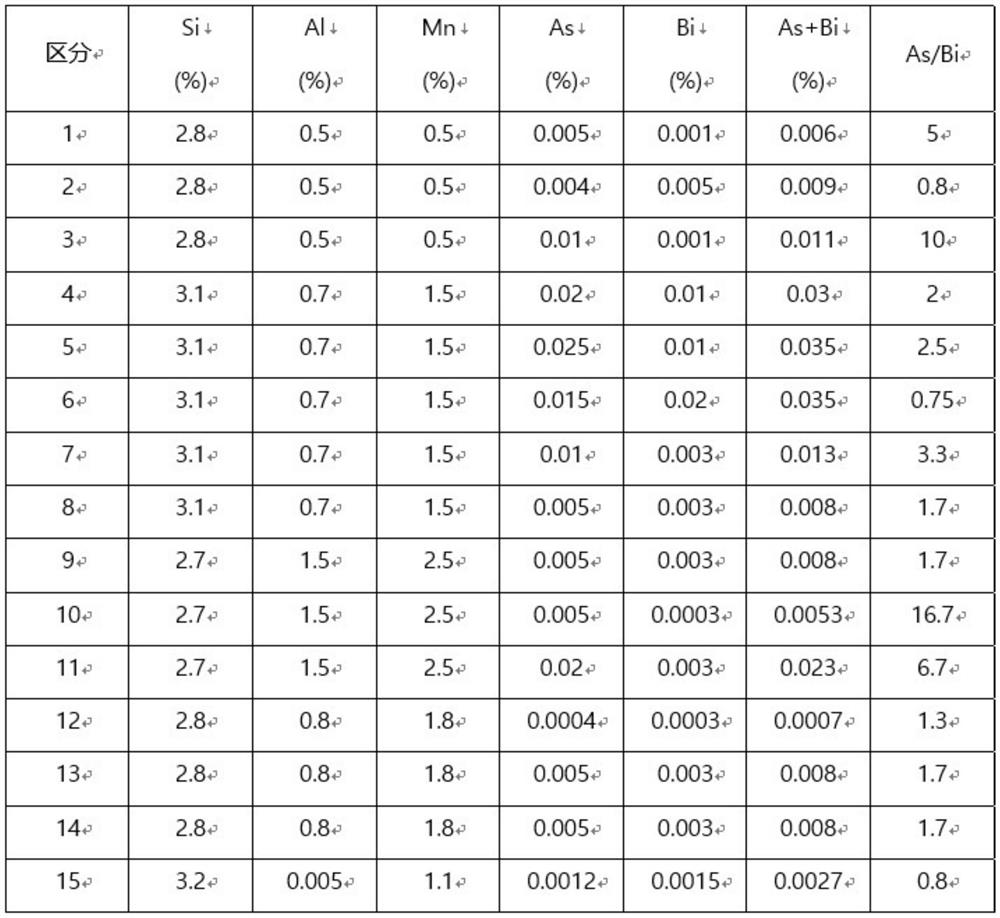

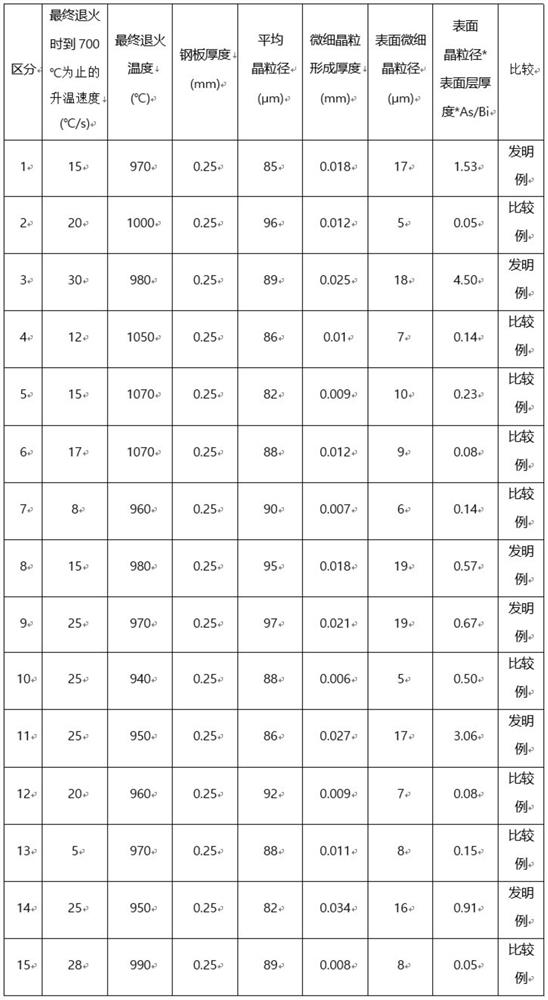

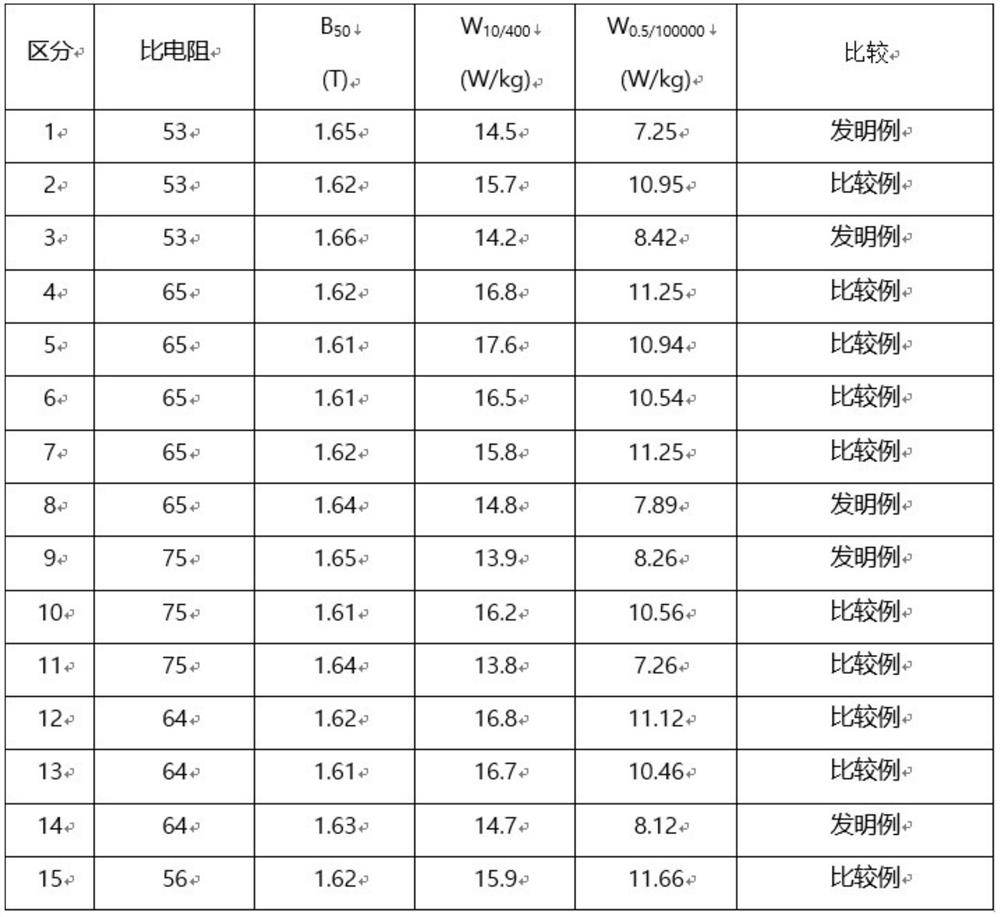

[0087] The method for preparing a non-oriented electrical steel sheet according to an embodiment of the present invention includes: a step of preparing a steel slab, the steel slab, in weight %, contains Si: 2.5 to 3.8%, Al: 0.5 to 2.5%, Mn: 0.2 to 4.5% %, As: 0.0005 to 0.02%, Bi: 0.0005 to 0.01%, and the balance of Fe and unavoidable impurities; the step of heating the billet; the step of preparing a hot-rolled sheet by hot rolling the heated billet; A step of preparing a cold-rolled sheet by cold-rolling the hot-rolled sheet; and a step of preparing an electrical steel sheet by subjecting the cold-rolled sheet to final annealing. In the step of final annealing the cold-rolled sheet, the heating rate up to 700° C. may be 10° C. / s or more. The following is a detailed description of each step.

[0088]First, a billet satisfying the above composition is prepared. The reason for limiting the addition ratio of each composition in the slab is the same as the reason for limiting t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com