Treatment method for fatigue test sample clamping part of hollow sucker rod

A technology of hollow sucker rod and fatigue test, which is applied in the field of laboratory testing, can solve the problems of easy fracture and inability to carry out fatigue test continuously, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below by specific embodiment and in conjunction with accompanying drawing, invention is described in further detail;

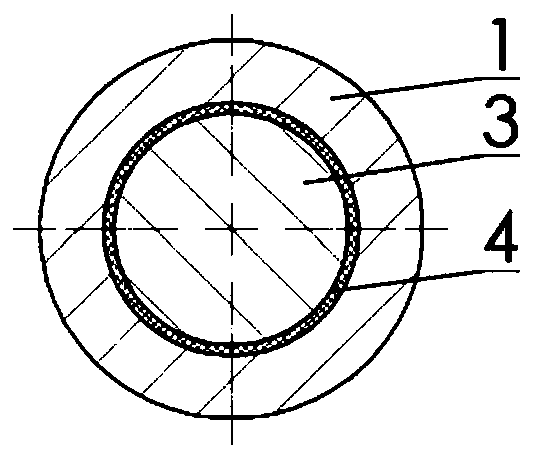

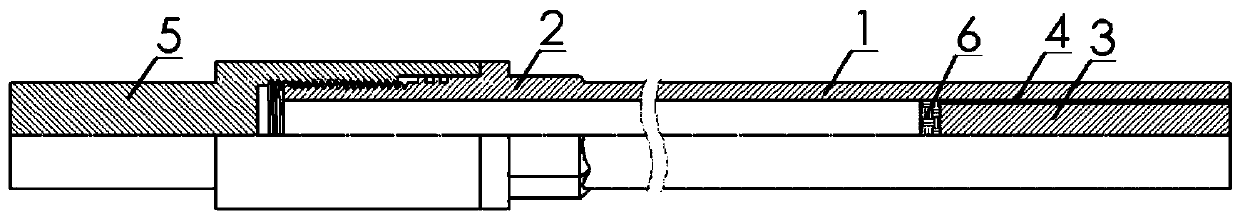

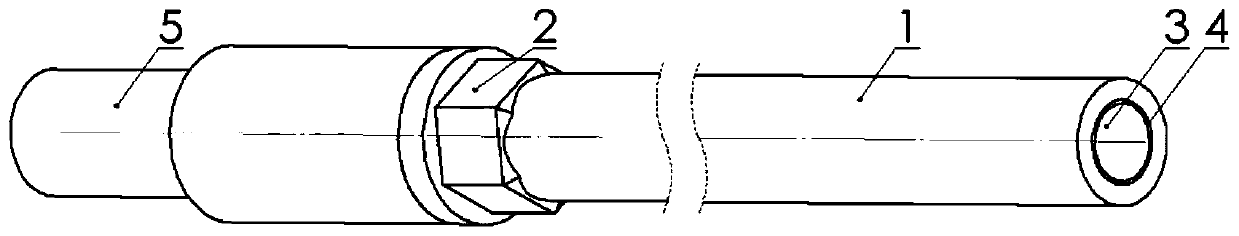

[0025] The sampling length of the hollow sucker rod is 700mm, the outer diameter of the rod body is 36.00mm, and the wall thickness is 6mm±0.25mm. One end is filled with a filling rod with a diameter of 22mm and the same material as the hollow sucker rod;

[0026] SDS300kN electro-hydraulic servo fatigue testing machine is used for fatigue performance test, the sample is clamped by clamp block, the length of the clamping part is 66mm, and the length of the filling rod is 99mm;

[0027] The gap between the filling rod and the hollow sucker rod is required to be 1mm to 2mm, and the gap between the filler rod and the hollow sucker rod in this example is calculated to be 1mm; this example uses high-strength epoxy resin glue to fill the gap, and the epoxy resin glue is cured The final Shore hardness is 90D.

[0028] Specific steps are as follows:

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com