Novel freeze dryer using residual heat to recover defrosting water and operation method thereof

A technology of defrosting water and freeze dryers, which is applied in the field of new freeze dryers, can solve the problems of high cost, large temperature fluctuations, and shortened service life, so as to reduce the damage caused by frequent start and stop, high temperature control accuracy, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

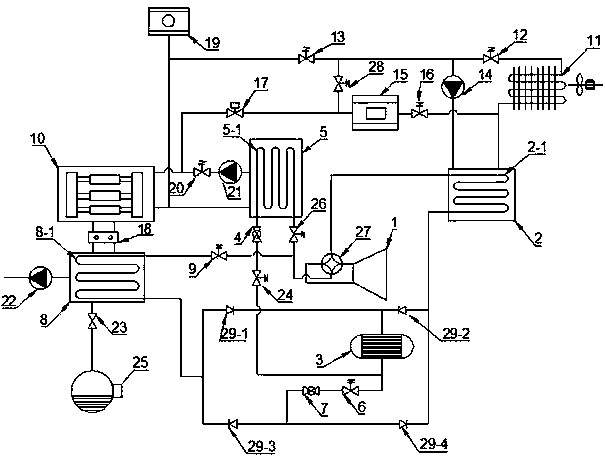

[0044] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

[0045] Three-way valves use "up", "down", "left" and "right" to indicate the direction of the valve port, and "left down", "left up", "right down", "right up", "up right", "down" Left", "down right", "left and right", "up and down", "up and down" indicate the communication and flow direction of the two valve ports in this direction.

[0046] "Left lower" means that the fluid medium flows in from the left valve port of the three-way valve and flows out from the lower valve port;

[0047] "Upper left" means that the fluid medium flows in from the left valve port of the three-way valve and flows out from the upper valve port;

[0048] "Bottom right" means that the fluid medium flows in from the right valve port of the three-way valve and flows out from the lower valve port;

[0049] "Upper right" means that the fluid medium flows in from the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com