Solar power generation system and method adopting non-tracking heat collector and linear power generator

A linear generator and power generation system technology, applied in solar thermal power generation, mechanical power generated by solar energy, machines/engines, etc., can solve the problems of low-temperature waste heat power generation, such as inapplicability, high cost, and low concentration efficiency, and achieve low-cost The effect of processing and manufacturing process, reducing pressure level and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

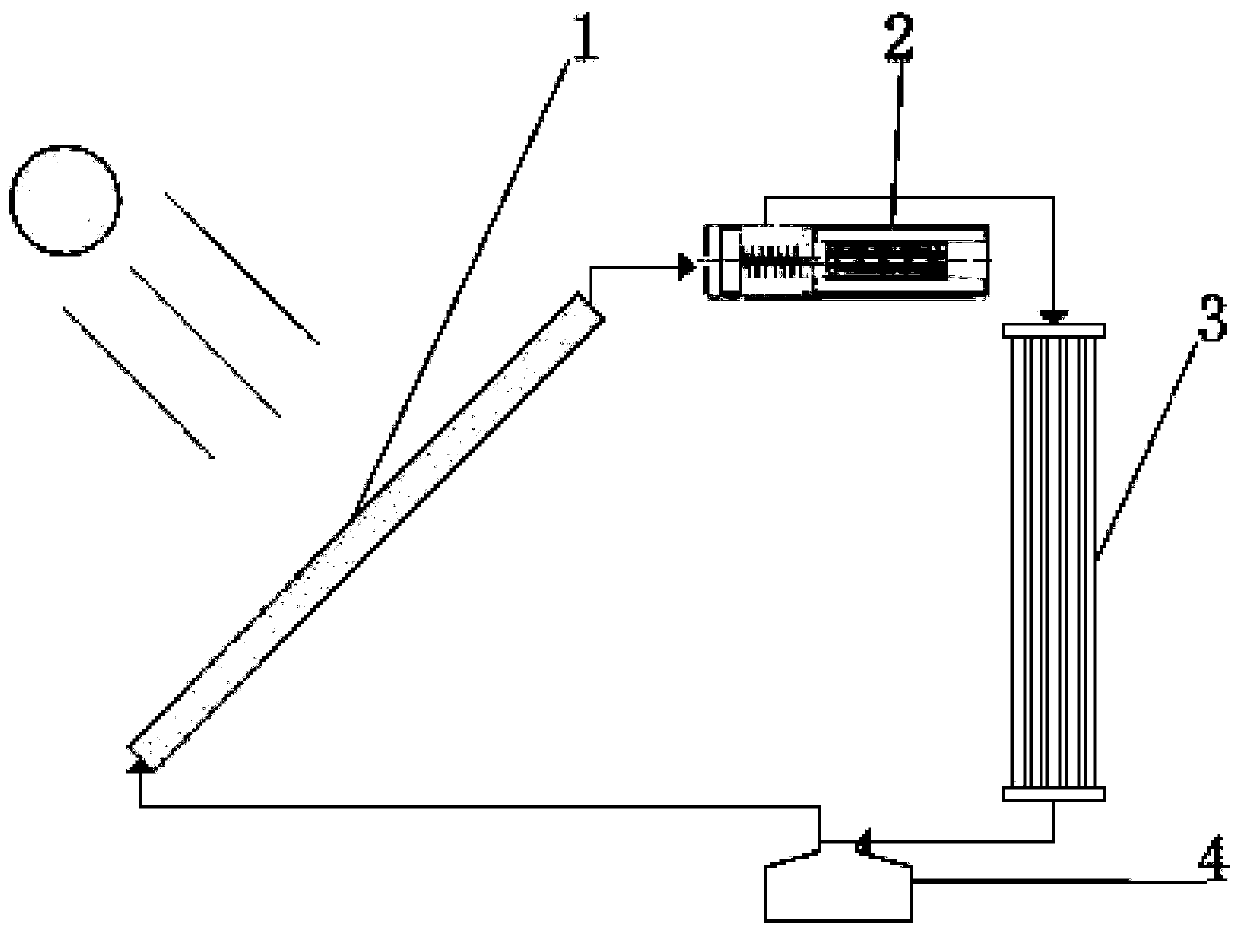

[0028] The solar power generation system that adopts non-tracking heat collector and linear generator described in the present invention, such as figure 1 As shown, it includes non-tracking solar collector 1, piston expansion-linear generator system 2, condenser 3, and liquid reservoir 4; the working medium side outlet of non-tracking solar collector 1 and piston expansion-linear generator system 2 The working medium side inlet is connected, piston expansion-linear generator system 2 The working medium side outlet is connected to the condenser 3 The working medium side inlet is connected, the condenser 3 Working medium side outlet is connected to the liquid storage 4 inlet, and the liquid storage 4 The outlet is connected to the inlet on the working medium side of the non-tracking solar colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com