Construction method for support-free hanging mold tool of horizontal post-cast strip

A construction method and technology of post-casting belts, which are applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and preparation of building components on site. It can solve the problem of large steel pipes, time-consuming installation and disassembly. Problems such as labor and occupation of the lower space of the post-casting belt, etc., to avoid the space occupied by steel pipes, avoid occupying space, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, a construction method for a horizontal post-casting belt free-supporting formwork tool, including a post-casting belt construction method at a non-laminated slab site, and a post-casting belt construction method at a non-laminated slab site comprising the following steps:

[0021] According to the position, width and plate thickness of the post-casting belt, determine the combination of different forms of templates, pull screws, embedded parts, wooden beams, square steel main beams and upper square steel hanging beams; draw the processing diagram of the mold hanging mold tools; Propose material planning and procurement; processing of hanging mold setting tools; installation of embedded parts on both sides of post-casting belt; installation of customized hanging mold tools; post-casting belt pouring; formwork removal and maintenance.

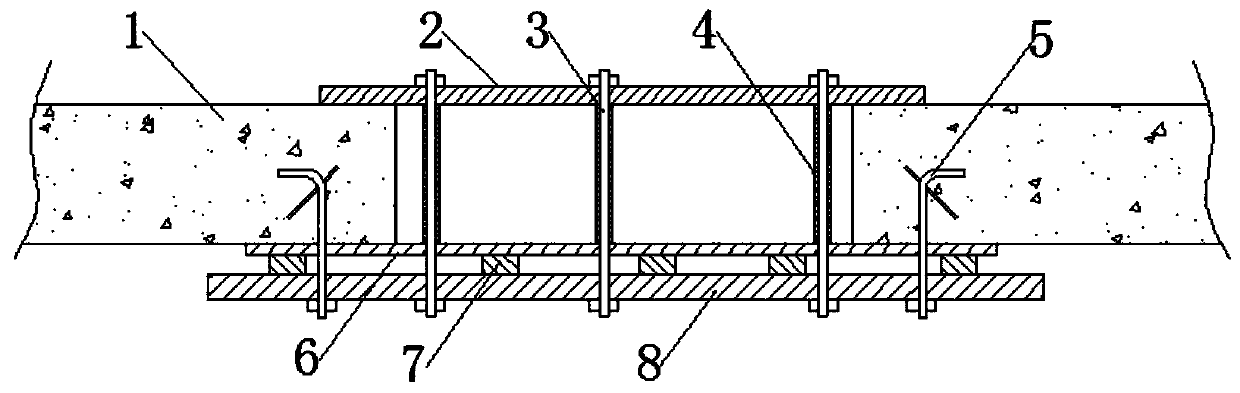

[0022] For details, please refer to figure 1 As shown, the setting hanger tool in the construction method of the horizontal...

Embodiment 2

[0023] Embodiment 2, a construction method for a support-free formwork tool for horizontal post-casting, including a construction method for a laminated slab, is characterized in that:

[0024] The post-casting tape construction method of the laminated slab part includes the following steps:

[0025] Draw the processing drawing of the mold hanging tool; propose material plan and procurement; processing of the mold hanging tool; installation of the mold hanging tool; post-casting belt and slab concrete pouring;

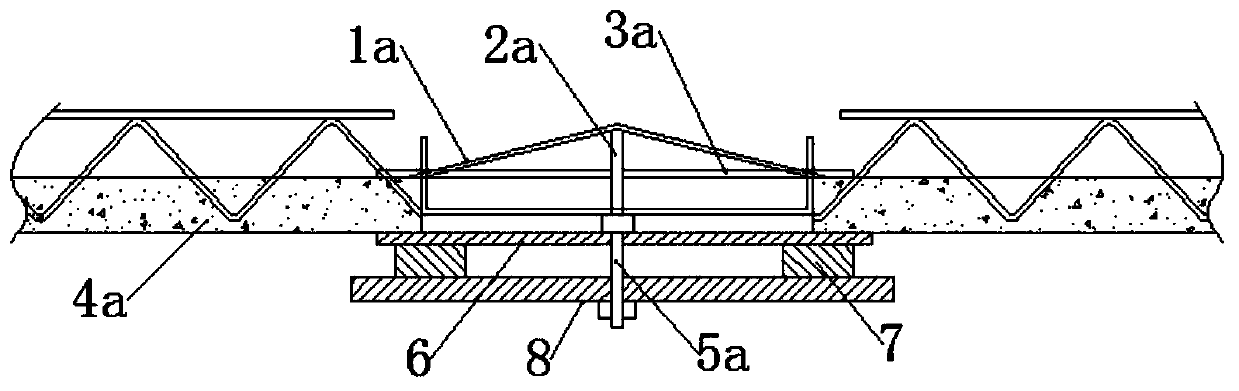

[0026] For details, please refer to figure 2 As shown, the hanging mold setting tool in the construction method of the horizontal post-cast belt at the laminated slab part includes a laminated slab 4a, a horizontal post-cast belt is reserved on the laminated slab 4a, and the upper end surface of the laminated slab 4a is located at the position of the horizontal post-cast belt. There is a horizontal support bar 3a, a herringbone-shaped reinforcing bar 1a is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com