Airflow sterilization system suitable for powdery and granular materials

A sterilizing system and airflow technology, which can be applied in sanitary equipment for toilets, applications, food science, etc., can solve problems such as complex swing structure, unfavorable cleaning and maintenance, and high cost, so as to solve the problem of limited space and improve space utilization , the effect of preventing material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

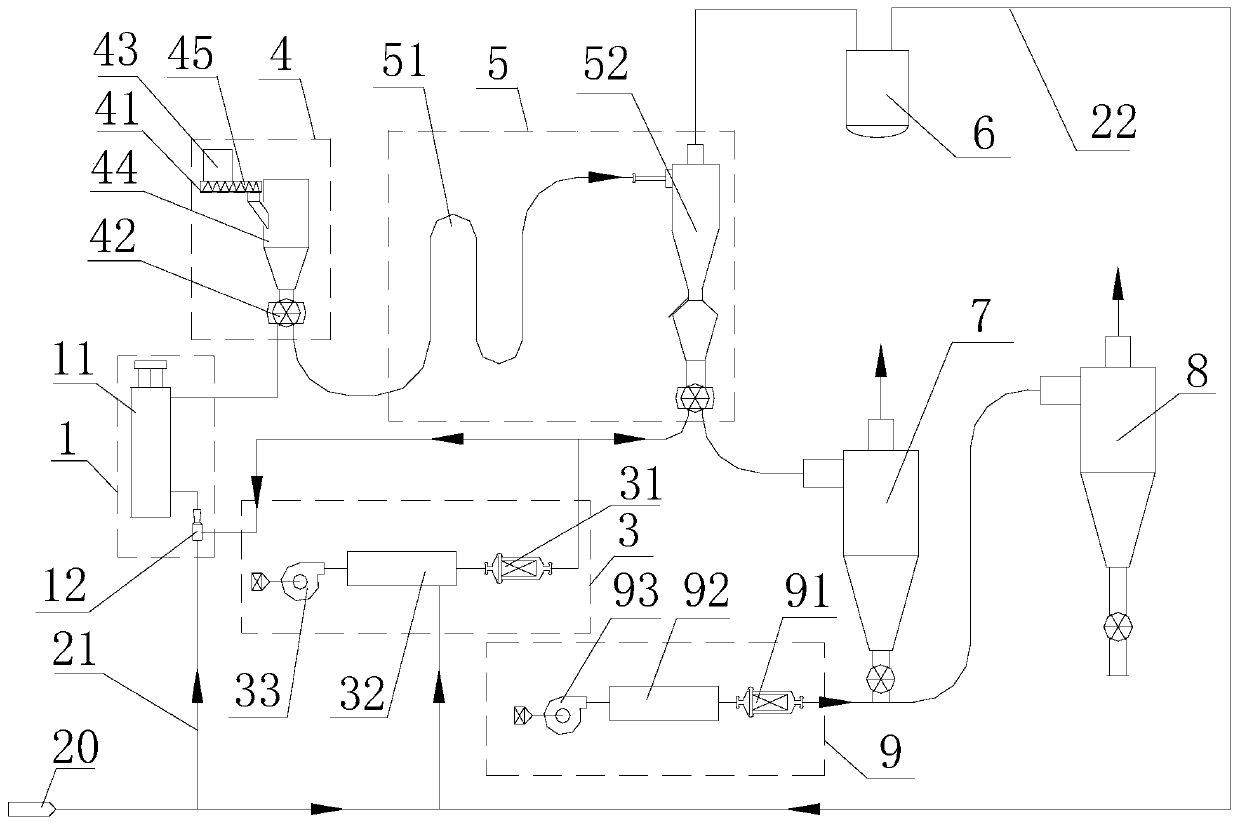

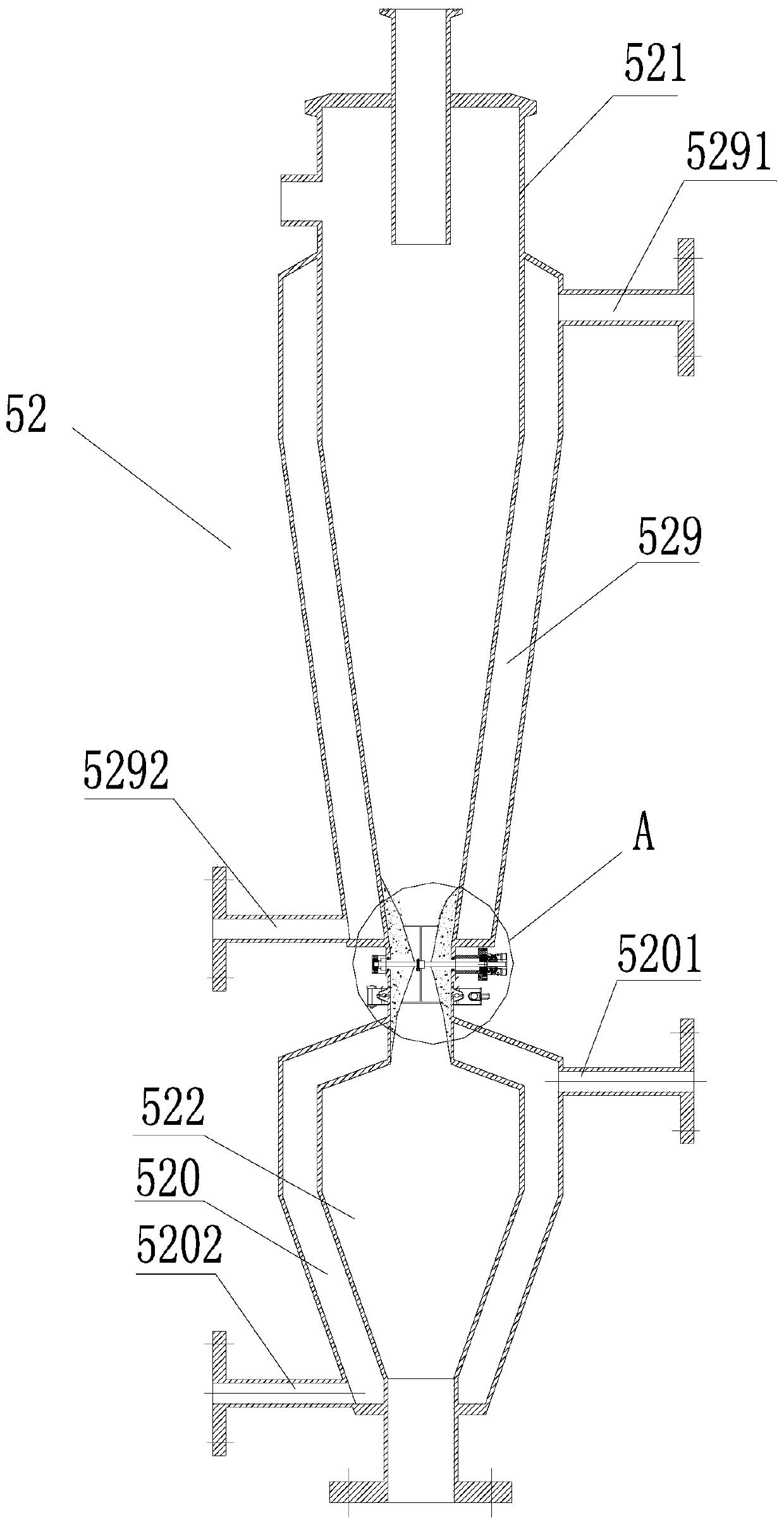

[0051] The airflow sterilization system suitable for powder and granular materials of the present invention will be further described in detail below in conjunction with specific drawings.

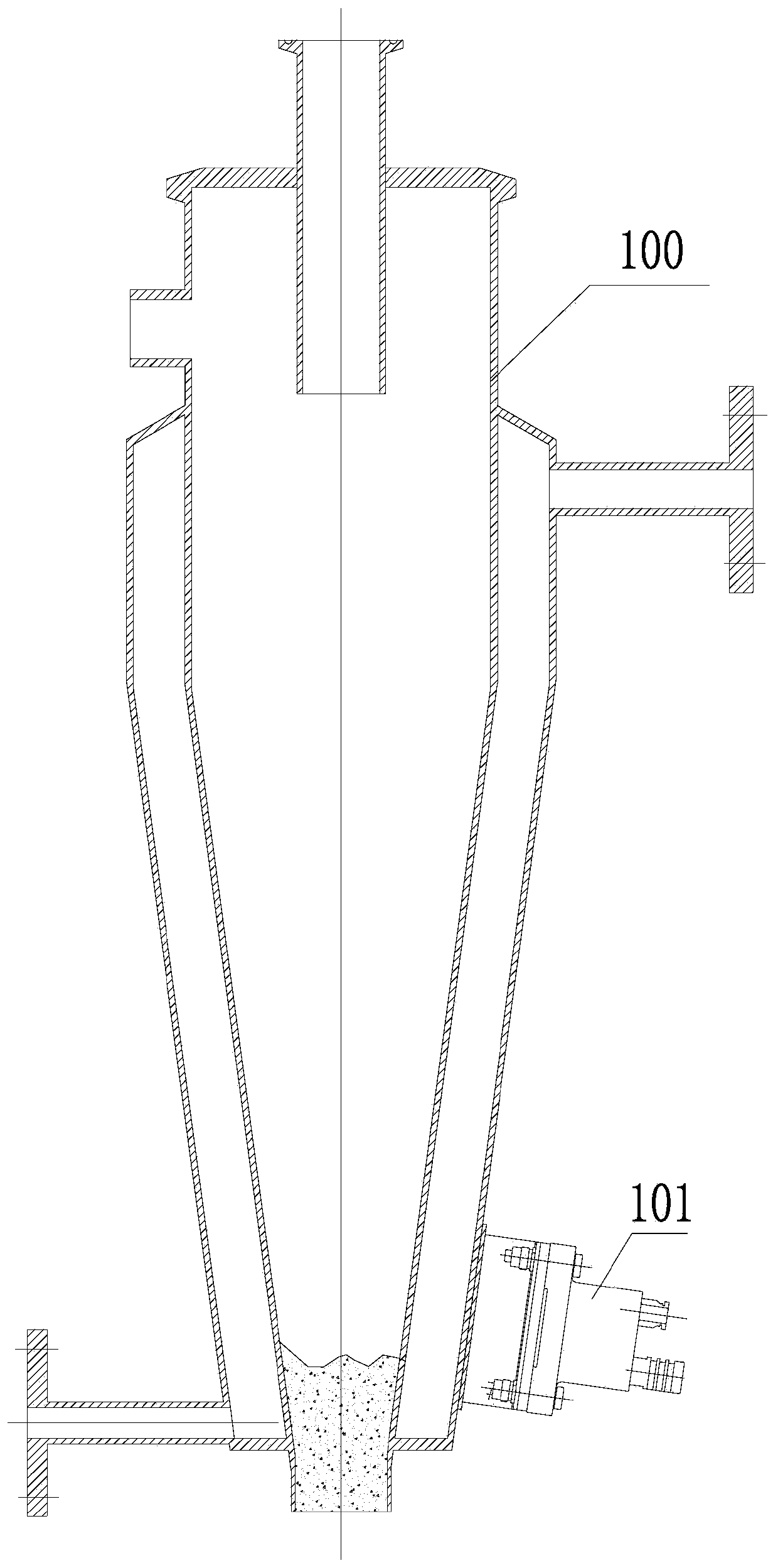

[0052] Such as figure 2 As shown, it is a kind of airflow sterilization system suitable for powder and granular materials of the present invention, including:

[0053] The gas flow supply device 1 is used to provide the sterilizing gas flow under the process conditions, the gas flow supply device 1 includes a gas flow heater 11, the inlet of the gas flow heater 11 is provided with a gas mixing nozzle 12, and the gas mixing nozzle 12 They are respectively connected with steam main pipe 21 and air heating device 3 for mixing steam and air to prevent steam from condensing. Normally, the ratio of hot air to steam can be set at 1:9-9.5, which can ensure that the steam does not condense, thereby preventing the material from getting wet and blocking the tube. Moreover, using the amount of stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com