Agarose gel substrate cultivated Aglaonema modestum potted plant and preparation method thereof

An agarose gel and substrate cultivation technology, which is applied in planting substrates, botanical equipment and methods, cultivation and other directions, can solve the problems of low unfavorable plant survival and growth, difficult quantitative control of physical and chemical properties, and easy spillage of nutrient solution, etc. The watering cycle is flexible, the ornamental value is increased, and the maintenance is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

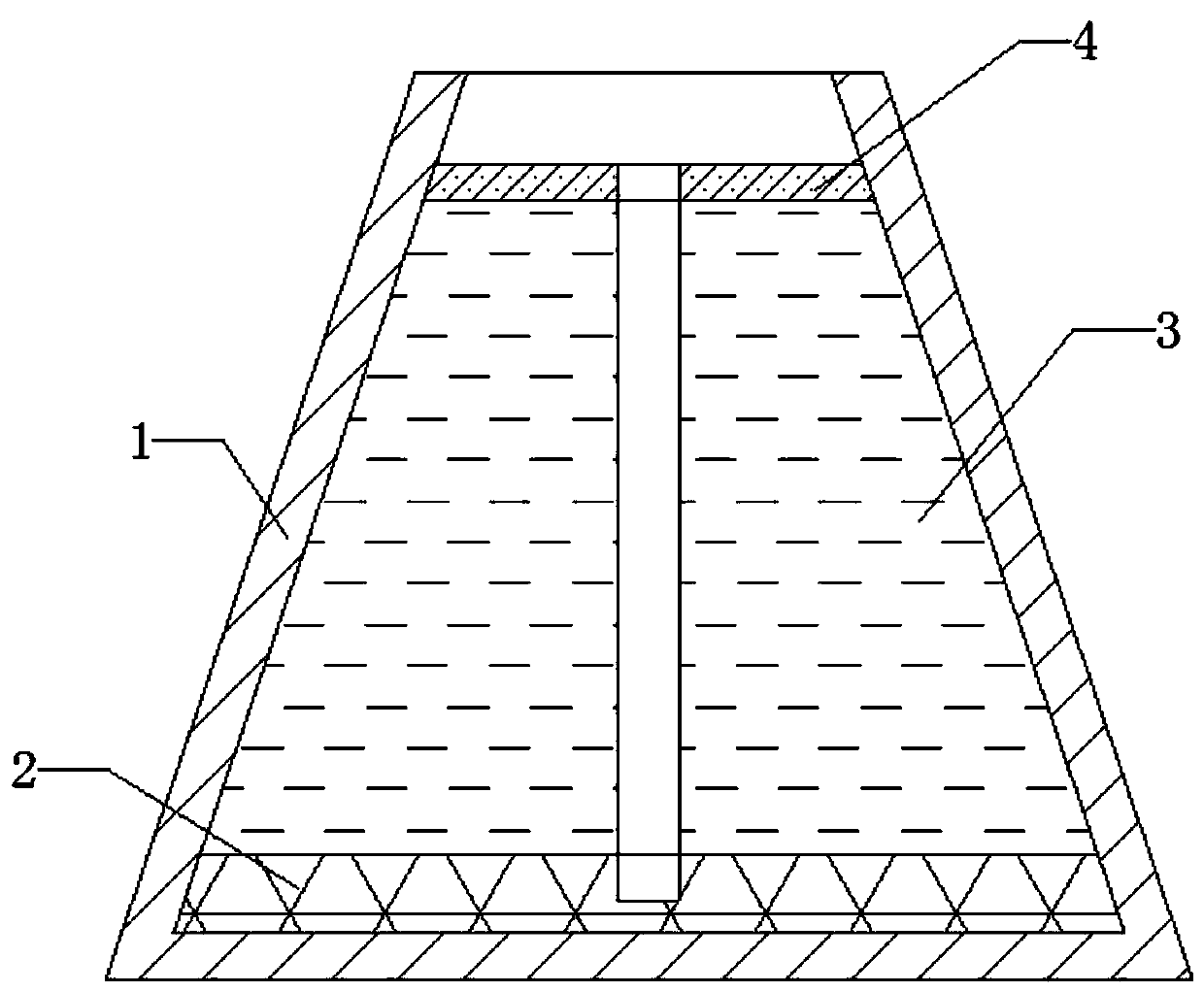

[0023] A preparation method based on the above-mentioned agarose gel matrix for cultivating Rhubarb potted plants, which comprises the following steps:

[0024] Step 1: Add 8~10g agarose, 2.4~4.8g ammonium sulfate, 5.4~10.8g magnesium sulfate, 6.6~12.2g calcium nitrate, 2.5~5g potassium sulfate and 3.5~7g potassium phosphate into the beaker, then add 80% The volume of clean water needed and heated to boiling, then stir well, heat again until all is melted, then add 0.1g dehydrogenated ethylenediamine and stir well, finally adjust the pH with hydrogen chloride and sodium hydroxide, pour it into glass container 1 at room temperature Cool to solidification to obtain a high-concentration nutrient layer 2;

[0025] Step 2: Add 8-10g agarose, 0.1g dehydroethylenediamine, 0.24g ammonium sulfate, 0.54g magnesium sulfate, 1.26g calcium nitrate, 0.25g potassium sulfate, 0.35g potassium phosphate, 0.1-1% concentration of food Add the pigment and 0.1 to 1% concentration of water-soluble fragr...

Embodiment 1

[0027] Example 1: First add 8g of agarose, 2.4g of ammonium sulfate, 5.4g of magnesium sulfate, 6.6g of calcium nitrate, 2.5g of potassium sulfate and 3.5g of potassium phosphate into a beaker, and then add 80% of the required clean water and heat to Boiling, then stir well, heat again until all is melted, then add 0.1g dehydrogenated ethylenediamine and stir well, finally adjust the pH with hydrogen chloride and sodium hydroxide, and the pH value is 6.5 ~ 7.5, pour into glass container 1 at room temperature Cooled to solidification to obtain a high-concentration nutrient layer 2, and then 8g agarose, 0.1g dehydroethylenediamine, 0.24g ammonium sulfate, 0.54g magnesium sulfate, 1.26g calcium nitrate, 0.25g potassium sulfate, 0.35g potassium phosphate, 0.1 Add ~1% food coloring and 0.1~1% water-soluble fragrance to the beaker, add 80% of the required clear water and heat to boiling, stir evenly, heat again until all is melted, add 0.1g dehydroethylene Mix the amine evenly, adjus...

Embodiment 2

[0028] Example 2: First add 10g of agarose, 4.8g of ammonium sulfate, 10.8g of magnesium sulfate, 12.2g of calcium nitrate, 5g of potassium sulfate and 7g of potassium phosphate into a beaker, then add 80% of the required clean water by volume and heat it to boiling, Then stir evenly, heat again until all is melted, add 0.1g dehydrogenated ethylenediamine and stir evenly, finally adjust the pH with hydrogen chloride and sodium hydroxide, and the pH is 6.5 ~ 7.5, pour into glass container 1 and cool to room temperature naturally A high-concentration nutrient layer 2 is obtained by solidification, and then 10g agarose, 0.1g dehydroethylenediamine, 0.24g ammonium sulfate, 0.54g magnesium sulfate, 1.26g calcium nitrate, 0.25g potassium sulfate, 0.35g potassium phosphate, 0.1~1 Add 5% concentration of food coloring and 0.1~1% concentration of water-soluble fragrance to the beaker, add 80% volume of the required clear water and heat to boiling, stir evenly, heat again until all is mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com