Chip packaging method and chip packaging structure

A chip packaging structure and chip packaging technology, applied in radiation control devices, semiconductor devices, electrical components, etc., can solve the problems of complicated procedures and high packaging requirements, and achieve good photosensitive effect, use less materials, and reduce the number of refractions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

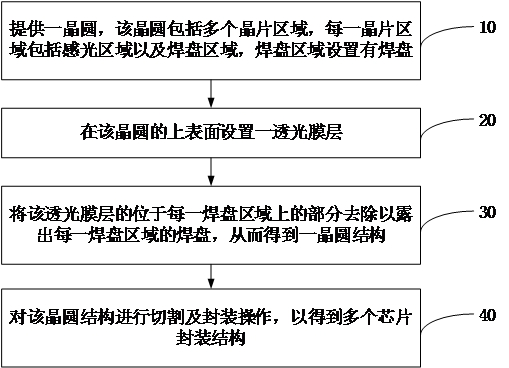

[0026] The embodiment of the present application provides a chip packaging method, which can be used in the packaging process of light-transmitting chips (CIS chips). chip package. figure 1 shows a flowchart of a chip packaging method, as figure 1 As shown, the chip packaging method includes:

[0027] Step 10: providing a wafer, the wafer includes a plurality of wafer areas, each wafer area includes a photosensitive area and a pad area, and the pad area is provided with pads.

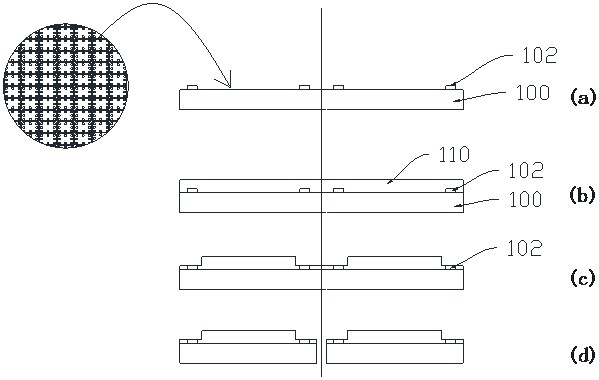

[0028] figure 2 A schematic diagram of a wafer is shown, and the wafer 100 includes a plurality of wafer regions 101 , and each wafer region 101 is fabricated with required integrated functional circuits, and the integrated functional circuits convert sensed optical signals into electrical signals. The wafer 100 includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com