Microwave chip eutectic welding platform and eutectic welding method

A microwave chip, eutectic welding technology, applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of poor clamping stability and inflexible switching of small-sized metal carriers, and achieve flexible conversion of fixed positions. , the effect of simple fixation and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

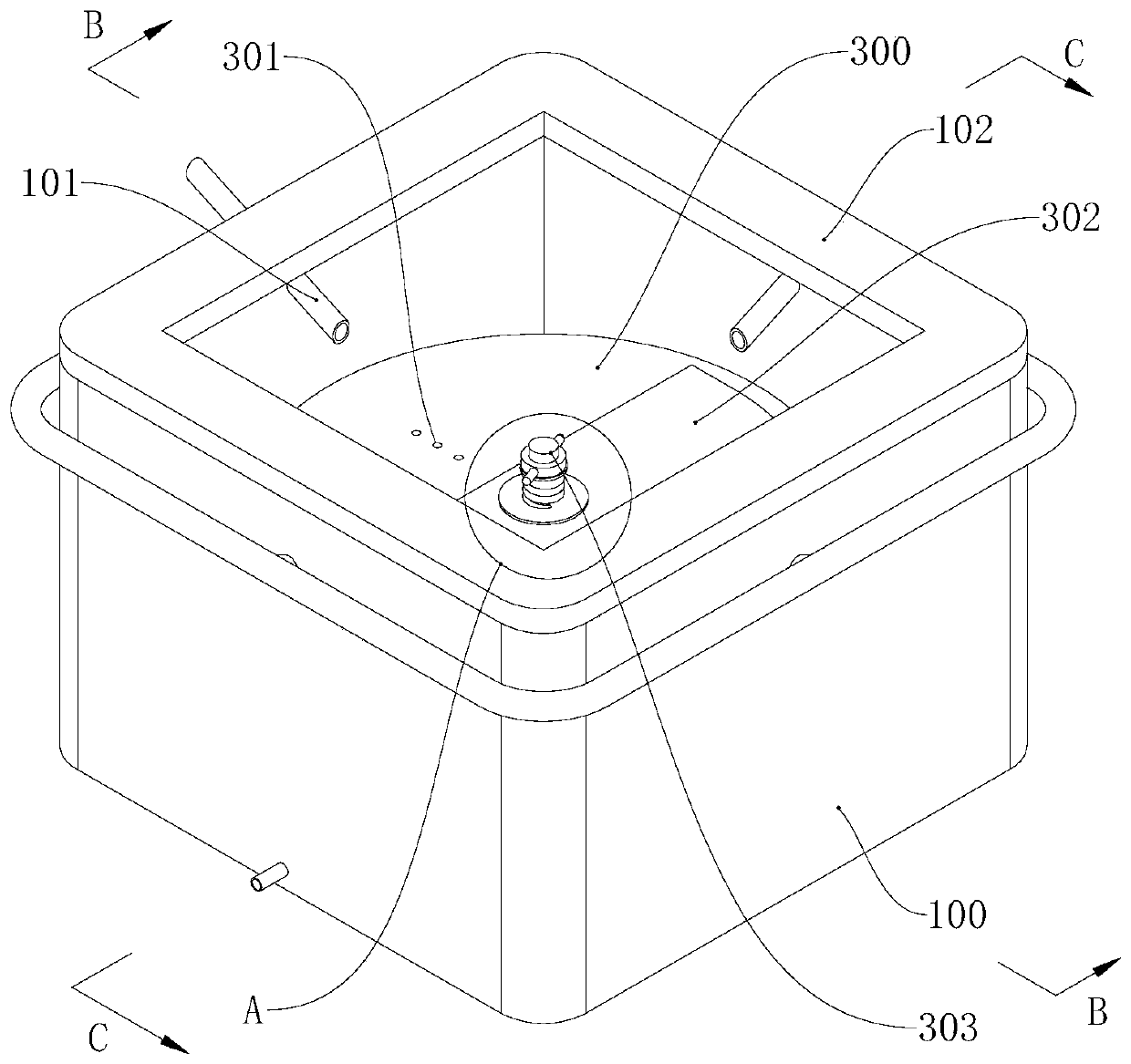

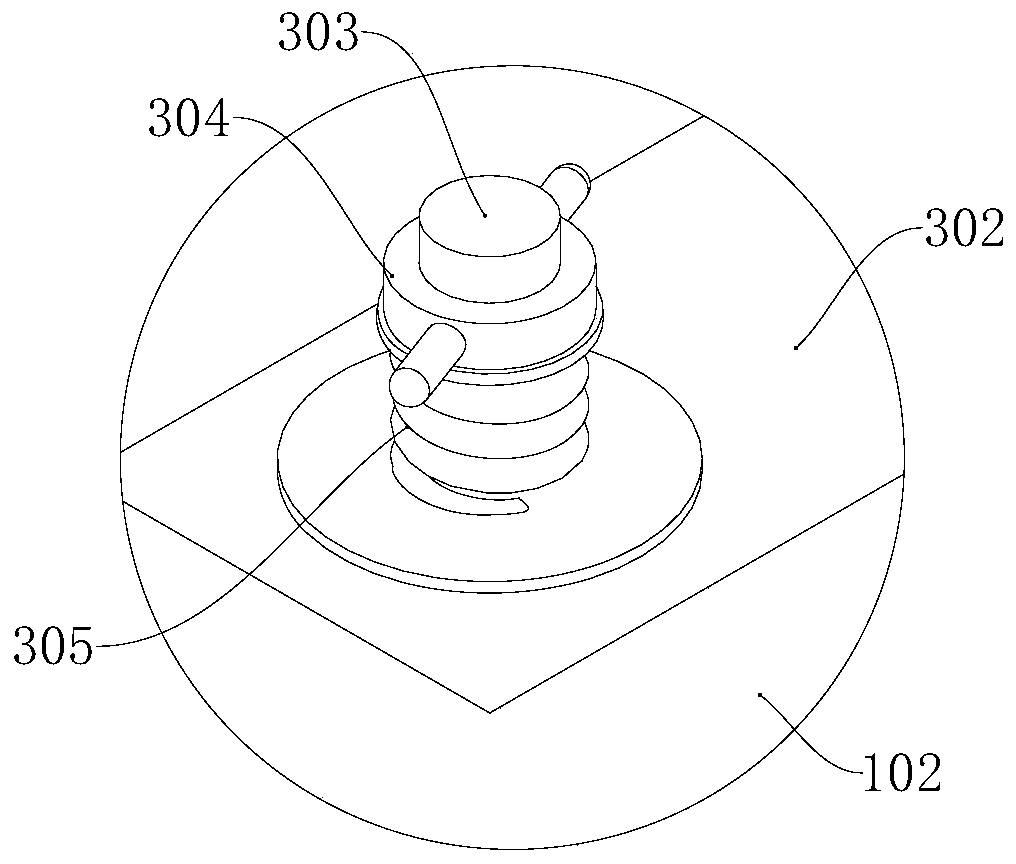

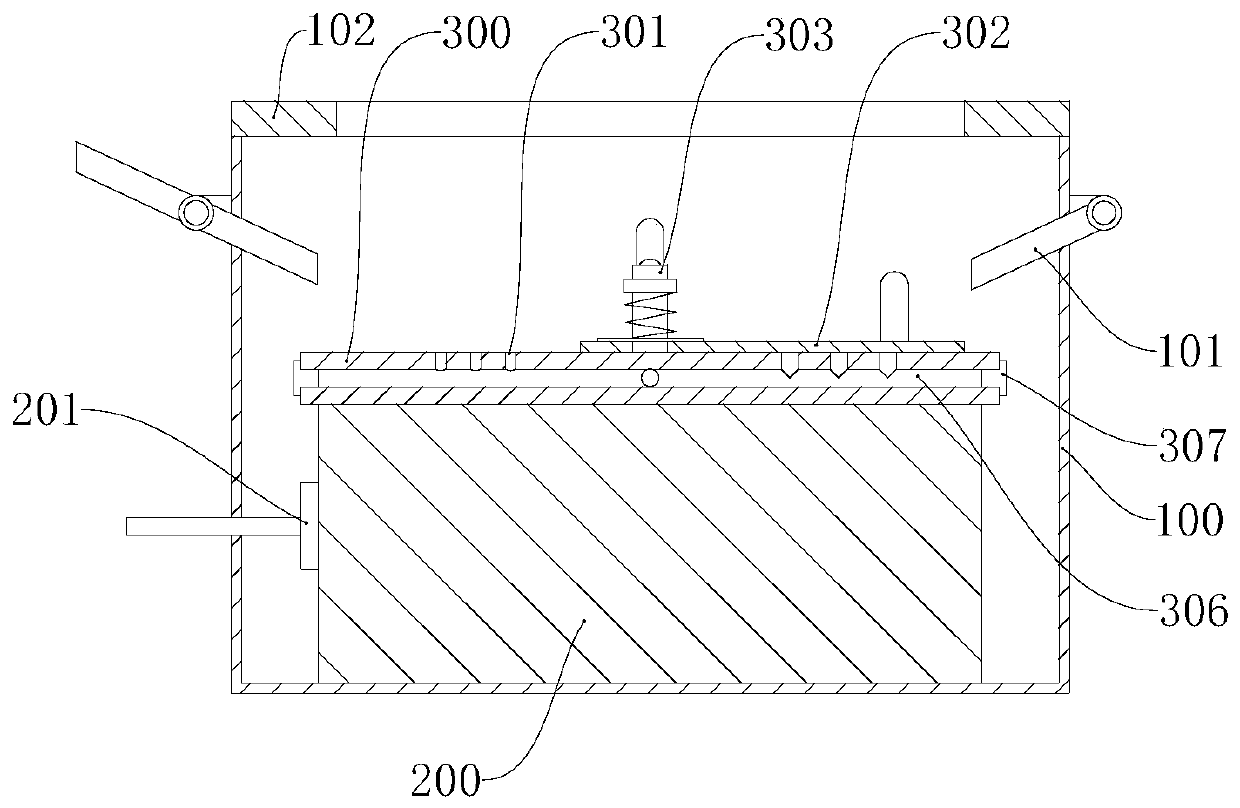

[0037] Please also refer to figure 1 , Figure 3 to Figure 5 , the microwave chip eutectic soldering platform provided by the present invention will now be described. The microwave chip eutectic welding platform includes a housing 100, a heating platform 200 and a working platform 300; the top of the housing 100 is open; the heating platform 200 is located inside the housing 100 for electrical connection with an external power supply; the working platform 300 is located inside the housing 100, and the bottom surface is attached to the top surface of the heating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com