Bearing defect rapid detection device for industrial robot and detection method thereof

A technology of industrial robots and detection devices, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as inability to detect, low detection efficiency, poor detection effect, etc., to avoid detection errors and improve detection accuracy , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

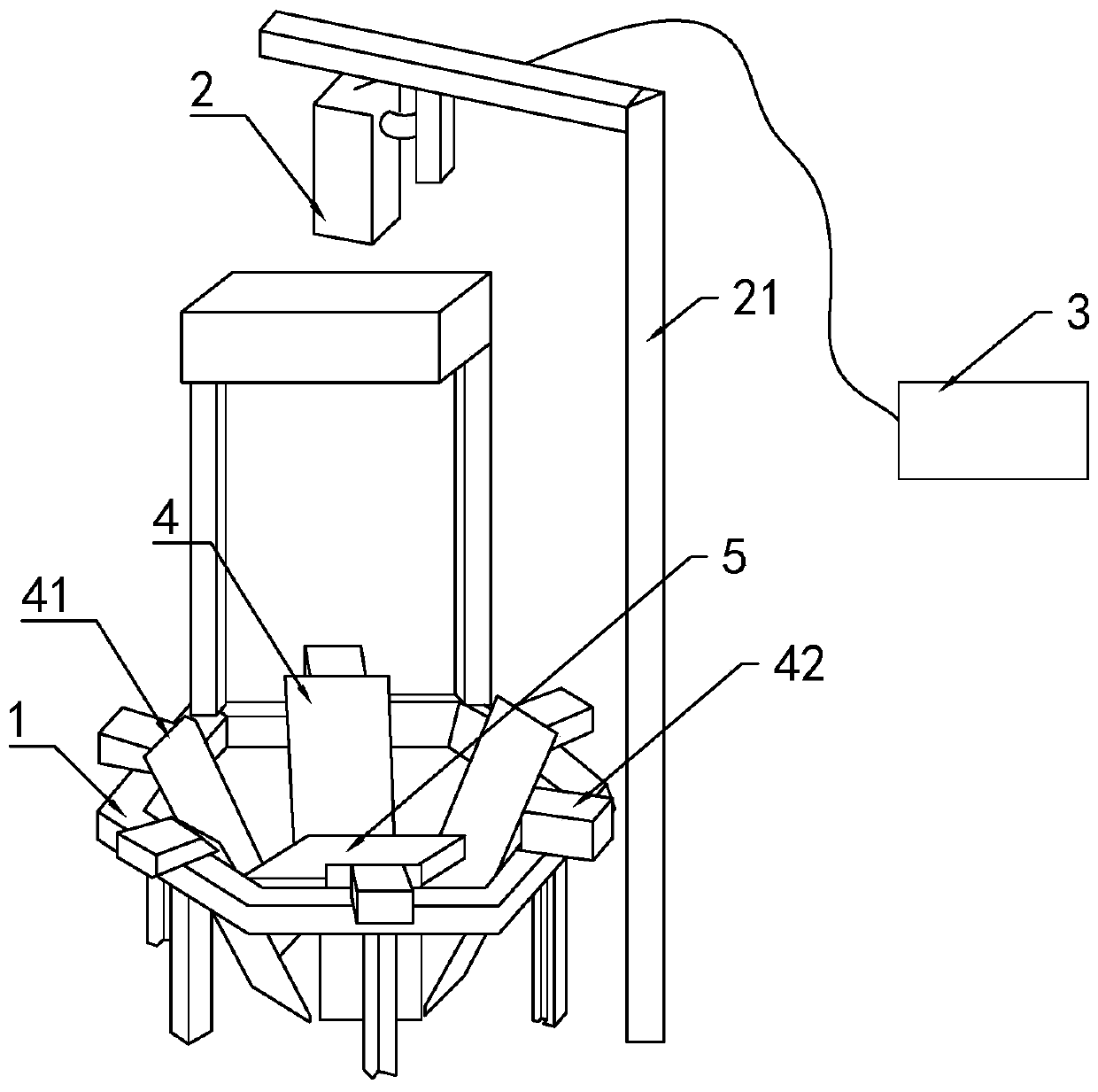

[0037] Such as figure 1As shown, the present invention discloses a quick detection device for bearing defects of industrial robots. In the specific embodiment of the present invention, it includes a frame 1, a matrix camera 2, a control panel 3, a plane mirror assembly 4 and a light supplement 5; The matrix camera 2 is installed on the frame 1 by the lifting frame 21 and is electrically connected with the control panel 3; the frame 1 directly below the matrix camera 2 is provided with a detection platform 5. Evenly installed on 5 circles of the detection platform; the plane mirror 41 is installed on the frame 1 through the plane mirror bracket 42; the light supplement 5 is installed on the frame 1 through the light supplement bracket 51.

[0038] Compared with the prior art, the beneficial effects brought by the present invention are: compared with the traditional line scan camera used for bearing surface detection and observation, the device adopts a rectangular camera for su...

Embodiment 2

[0039] Embodiment 2, the difference with embodiment 1 is

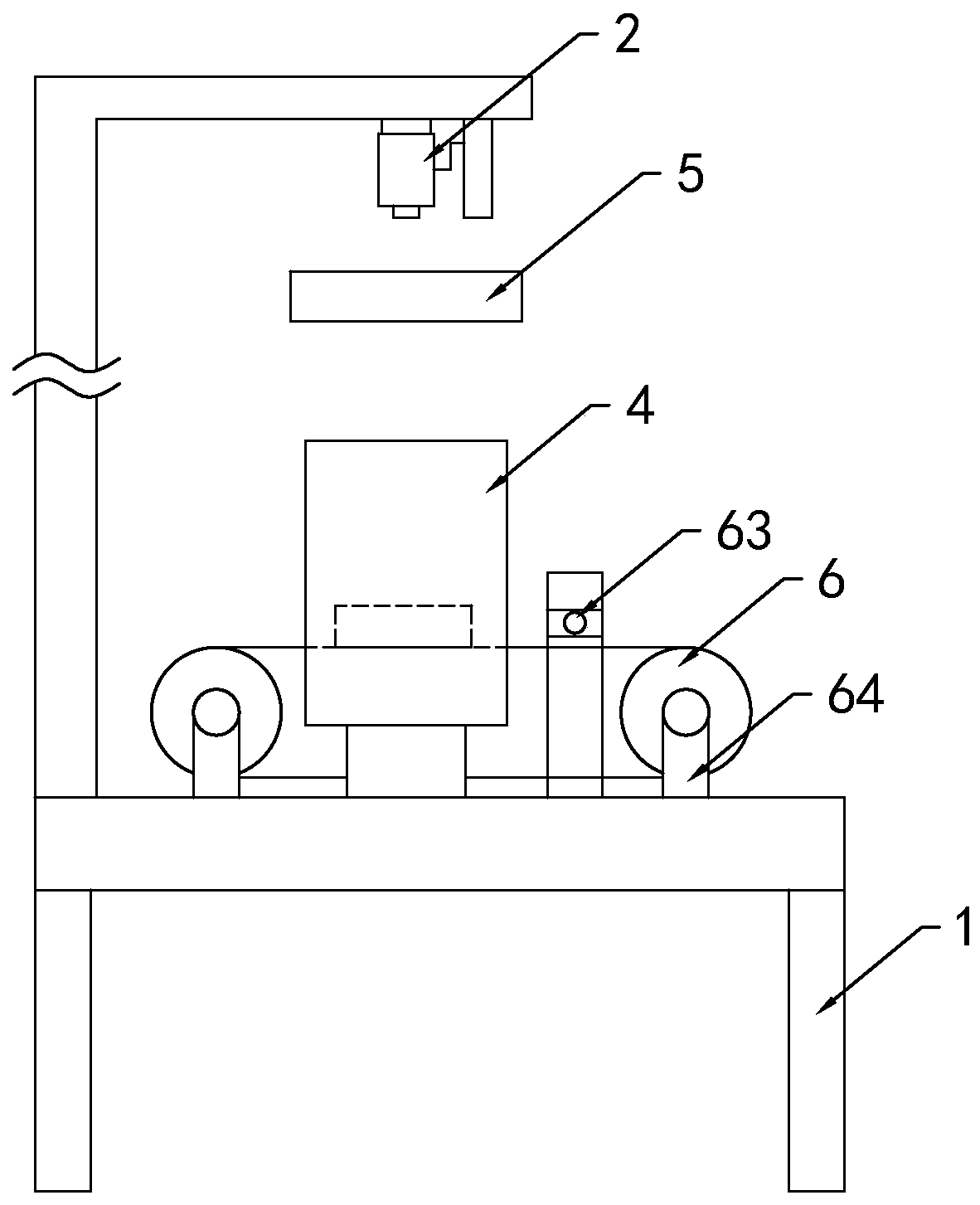

[0040] Such as Figure 2-4 As shown, in the specific embodiment of the present invention, a transport positioning device 6 for transporting bearings is installed on the frame 1 directly below the matrix camera 2; at least two plane mirrors 41 are installed on both sides of the transport positioning device 6.

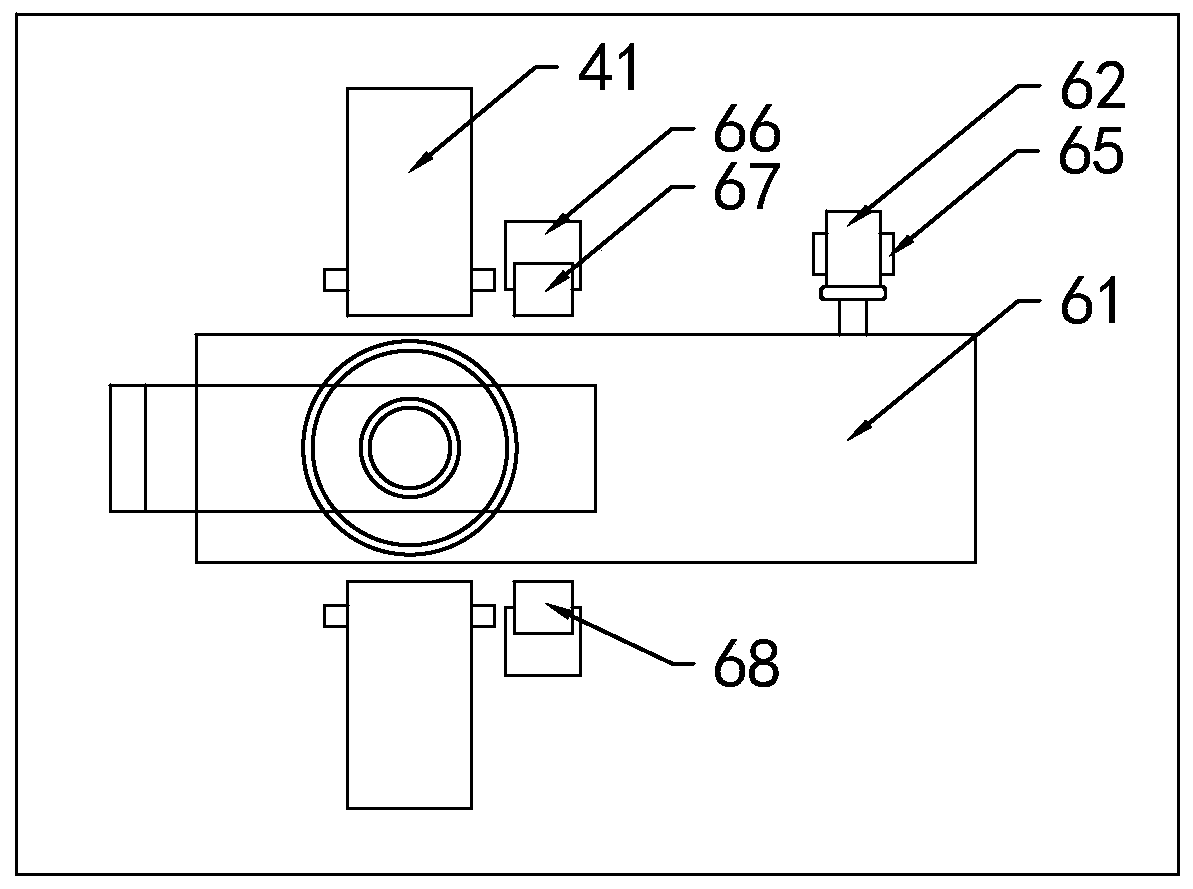

[0041] The transport positioning device 6 includes a conveyor belt 61, a servo motor 62 for driving the conveyor belt 61, and a laser detector 63; the conveyor belt 61 is installed on the frame 1 through a conveyor belt mounting frame 64; Installed on the frame 1 and the output end is fixedly connected to the driving shaft of the conveyor belt 61; the laser detector 63 is installed on the frame 1 by the detector support 66, and is positioned at the side of the matrix camera 2 toward the input end of the conveyor belt 61; The laser detector 63 includes a laser generator 67 and a laser receiver 68 installed on the...

Embodiment 3

[0044] Embodiment 3, the difference with embodiment 2 is

[0045] Such as Figure 5-6 As shown, in the specific embodiment of the present invention, the shown plane mirror 41 is installed on the frame 1 through the mirror surface adjustment part 7; The height of the lifting unit 72 and the vertical axis rotation unit 73 and the horizontal axis rotation unit 74 for adjusting the mirror angle of the plane mirror; the lifting unit 72 is installed on the mounting base 71, and the vertical axis rotation unit 73 is installed on the lifting unit 72 output end; the horizontal axis rotation unit 74 is installed on the vertical rotation unit 73 .

[0046] In a specific embodiment of the present invention, the lifting unit 72 includes a lower support body 721, an upper support body 722, an extrusion ring 723 and a positioning screw cover 724; the lower support body 721 is a hollow cylinder, and the upper support body 722 is Tubular; and one end of the lower support body 721 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com