Citrus microelement core master batch as well as preparation method and application thereof

A technology of trace elements and citrus, applied in application, organic fertilizer, nitrogen fertilizer, etc., can solve problems such as low yield, lower fertilizer utilization rate, and difficult to mix uniformly, so as to increase yield and quality, improve fertilizer utilization rate, and reduce nutrient loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

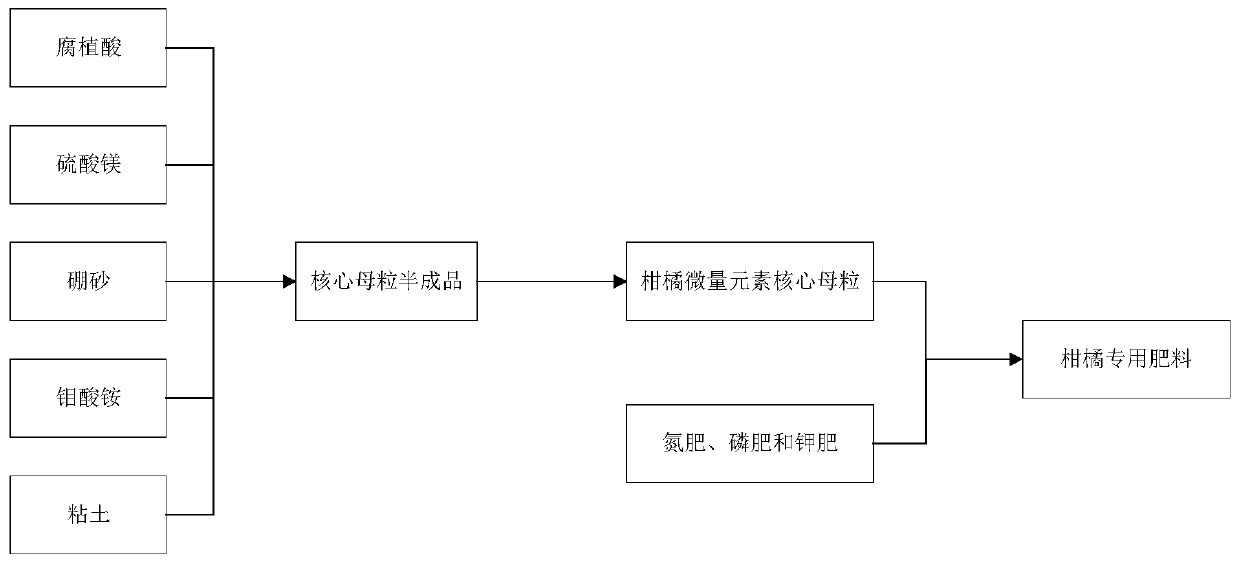

[0019] The present invention also provides a preparation method of the citrus microelement core masterbatch, comprising the steps of:

[0020] Prepare materials by weight, mix all components evenly, and carry out drum granulation at a temperature of 60-80°C and a material moisture content of 30-40% to obtain a semi-finished core masterbatch; the semi-finished core masterbatch is dried, After cooling, coating and sieving, the core masterbatch of citrus trace elements is obtained.

[0021] In some preferred embodiments of the present invention, the semi-finished core masterbatch is dried at 200-300°C until the moisture content of the semi-finished core masterbatch is 15-25%.

[0022] In some preferred implementations of the present invention, the semi-finished core masterbatch is cooled at 40-50° C. to avoid agglomeration of the semi-finished core masterbatch.

[0023] In some preferred embodiments of the present invention, during drum granulation, the rotational speed of the d...

Embodiment 1

[0031] Example 1 of the present invention provides a citrus trace element core masterbatch, which includes the following components by weight: 10 parts of humic acid, 3 parts of magnesium sulfate, 0.5 part of borax, 0.05 part of ammonium molybdate, and clay for filling To 100 parts, the citrus microelement core masterbatch is granular.

[0032] The citrus trace element core masterbatch is prepared by the following method:

[0033] (1) After mixing humic acid, magnesium sulfate, borax, ammonium molybdate and clay evenly, add them to the drum granulation system, and carry out drum granulation on the mixture at a temperature of 70°C and a moisture content of 35% to obtain the core Masterbatch semi-finished products;

[0034] (2) Add the core masterbatch semi-finished product into the drying system, dry it at a temperature of 250°C, then transfer it to the drum screening system, and pass through the drum screening system with a rotating speed of 15r / min. The semi-finished core m...

Embodiment 2

[0036] Example 2 of the present invention provides a citrus trace element core masterbatch, which includes the following components by weight: 13 parts of humic acid, 2 parts of magnesium sulfate, 0.3 part of borax, 0.02 part of ammonium molybdate, and clay for filling To 100 parts, the citrus microelement core masterbatch is granular.

[0037] The citrus trace element core masterbatch is prepared by the following method:

[0038] (1) After mixing humic acid, magnesium sulfate, borax, ammonium molybdate and clay evenly, add them to the drum granulation system, and carry out drum granulation on the mixture at a temperature of 60°C and a moisture content of 30% to obtain the core Masterbatch semi-finished products;

[0039] (2) Add the core masterbatch semi-finished product into the drying system, dry it at a temperature of 200°C, and then transfer it to the drum screening system. The core masterbatch semi-finished product is added to the cooling system, cooled at a temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com