A kind of nano enzyme, preparation method and application thereof

A nano-enzyme and enzyme-mimicking technology, which is applied in the field of nano-enzyme catalysis, can solve the problems of graphyne research and achieve the effects of more active sites, improved catalytic activity, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] It should be noted that the present invention also provides a method for preparing nitrogen-doped graphyne nanozyme, comprising the following steps:

[0041] Step S1, preparing graphyne oxide: using an oxidizing agent to oxidize the original graphyne to obtain graphyne oxide;

[0042] Step S2, annealing graphyne oxide in a nitrogen source to obtain nitrogen-doped graphyne nanozyme.

[0043] Specifically, in the above step S1, the oxidizing agent is strong acid, potassium permanganate or H 2 o 2 . In order to avoid introducing metal impurities, preferably, the oxidizing agent is a strong acid.

[0044] Specifically, in the above step S1, the step of using a strong acid as an oxidizing agent to oxidize the original graphyne includes:

[0045] S11. Mix the original graphyne with a strong acid, heat to 70-90°C (the temperature is too low, the reaction rate is slow; the temperature is too high, the strong acid is easy to decompose and volatilize), and keep warm for 2.5-3...

Embodiment 1

[0064] This embodiment provides a graphyne oxide, the preparation method is as follows:

[0065] Mix 40 mg of raw graphyne with 40 mL of concentrated HNO 3 / Concentrated H 2 SO 4 (1:3) mixed, reacted at 80°C for 3 hours, cooled to room temperature, added water and centrifuged several times, and when the pH of the supernatant was >6, the lower layer samples were collected and freeze-dried to obtain graphyne oxide (GDYO).

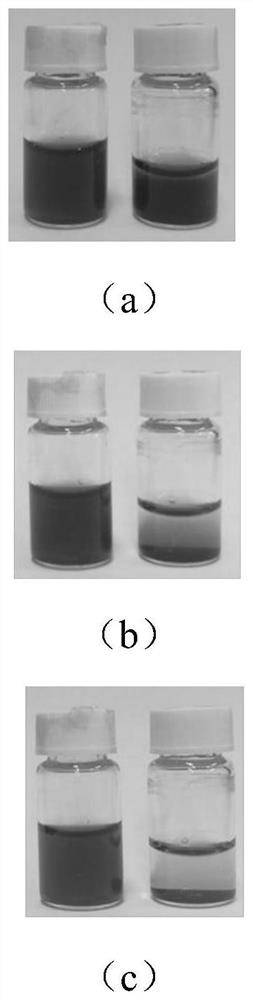

[0066] Among them, raw graphdiyne (GDY) is purchased from the conventional market. Such as figure 1 as shown, figure 1 It is a comparison chart of the dispersion of original graphyne and graphyne oxide; (a)-(c), the right side is original graphyne, the left side is graphyne oxide, (a) is the dispersion of original graphyne and graphyne oxide Photos after ultrasonication in water; (b) is the photo of pristine graphyne and graphyne oxide dispersed in water after ultrasonication for 10 min; (c) is the photo of original graphyne and graphyne oxide dispersed...

Embodiment 2

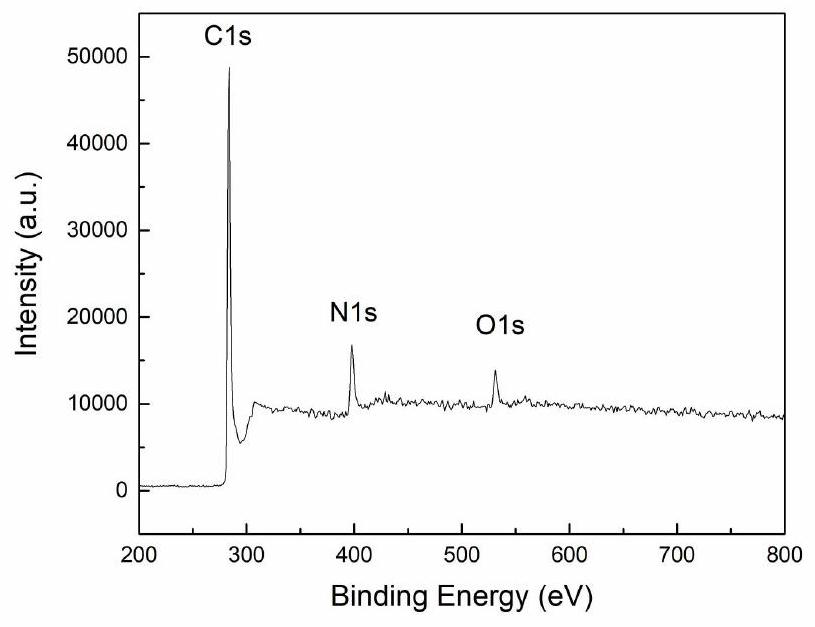

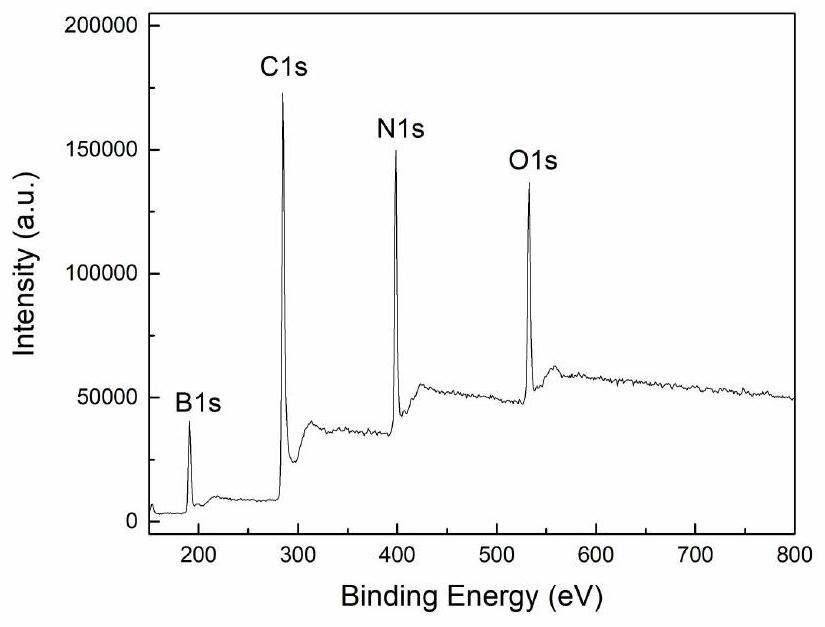

[0068] The present embodiment provides a nitrogen-doped graphyne nanozyme, wherein the nitrogen atomic percentage is 9.79% (such as figure 2 shown).

[0069] This embodiment also provides a nitrogen-doped graphyne nanozyme, the preparation method of which is as follows:

[0070] The graphyne oxide prepared in Example 1 was placed in a tube furnace and heated to 900° C. for 30 min under the protection of argon (flow rate of 200 sccm), and then fed into NH 3 Gas (flow rate: 20 sccm) was incubated at 900°C for 2h, and after cooling to room temperature with the furnace, nitrogen-doped graphyne nanozyme (N-GDY) was obtained.

[0071] The original graphyne nanozyme, oxidized graphyne nanozyme, and nitrogen-doped graphyne nanozyme are used as a method to simulate the catalytic activity of peroxidase:

[0072] (1) Disperse the original graphyne nanozyme, graphyne oxide nanozyme, and nitrogen-doped graphyne nanozyme into water respectively (the mass-volume ratio of graphyne nanozyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com