Tin telluride-based thermoelectric material and preparation method thereof

A thermoelectric material, tin telluride-based technology, applied in the direction of binary selenium/telluride compound, metal selenide/telluride, grain processing, etc., can solve the problems of potential safety hazards, environmental pollution, poor electrical conductivity, etc., and achieve reduction Lattice thermal conductivity, improve electrical conductivity, and solve the effect of poor electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

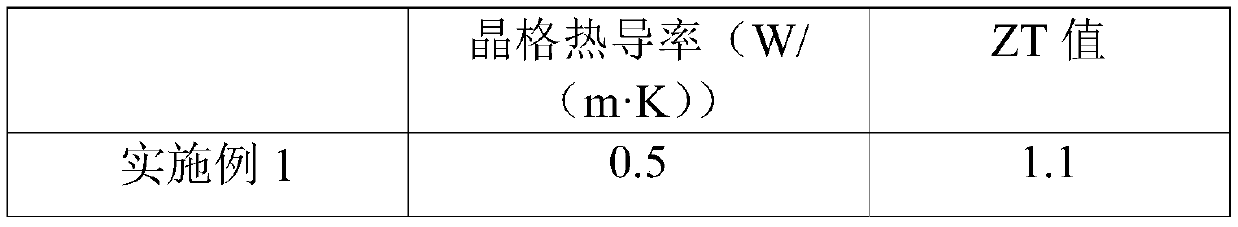

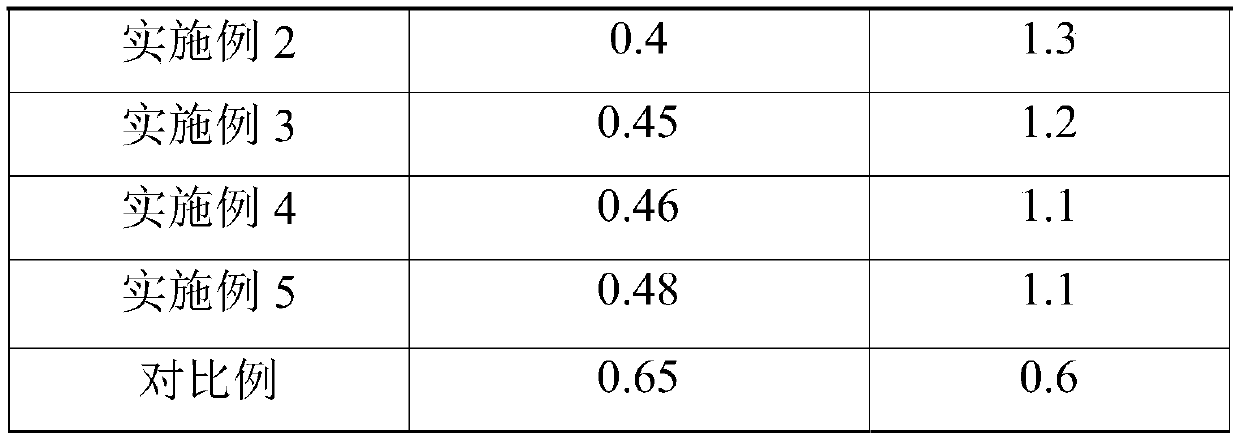

Embodiment 1

[0024] A tin telluride-based thermoelectric material comprises the following components: tellurium, tin and aluminum, the molar ratio of tellurium, tin and aluminum is 1:1.9:0.06; the purity of tellurium, tin and aluminum is above 99.9%.

[0025] The preparation method of the above-mentioned tin telluride-based thermoelectric material comprises the following steps:

[0026] (1) Weigh tellurium, tin and aluminum respectively in an argon environment and mix them evenly to obtain mixed raw materials, then add them to a ball mill jar, vacuumize and feed the mixed gas, first ball mill at 100rpm for 1 hour, and then grind the balls and mix The mass ratio of raw materials is 1:20, and then ball milled at 400rpm for 15 hours to obtain mixed powder; the mixed gas is a gas mixed with hydrogen and argon at a volume ratio of 5:95; every 2 hours of ball milling, cooling for 15 minutes;

[0027] (2) The mixed powder obtained in step (1) was heated to 550° C. for 2 minutes for plasma sinteri...

Embodiment 2

[0029] A tin telluride-based thermoelectric material comprises the following components: tellurium, tin and aluminum, the molar ratio of tellurium, tin and aluminum is 2:1.98:0.05; the purity of tellurium, tin and aluminum is above 99.9%.

[0030] The preparation method of the above-mentioned tin telluride-based thermoelectric material comprises the following steps:

[0031] (1) Weigh tellurium, tin and aluminum respectively in an argon environment and mix them uniformly to obtain mixed raw materials, then add them to a ball mill jar, vacuumize and feed the mixed gas, first ball mill at 120rpm for 2 hours, and the balls and mix The mass ratio of raw materials is 1:20, and then ball milled at 450rpm for 18 hours to obtain a mixed powder; the mixed gas is a gas mixed with hydrogen and argon at a volume ratio of 5:95; every 2 hours of ball milling, cooling for 15 minutes;

[0032] (2) Plasma sintering the mixed powder obtained in step (1) to 600° C. for 6 minutes, the heating rat...

Embodiment 3

[0034] A tin telluride-based thermoelectric material comprises the following components: tellurium, tin and aluminum, the molar ratio of tellurium, tin and aluminum is 2:2:0.04; the purity of tellurium, tin and aluminum is above 99.9%.

[0035] The preparation method of the above-mentioned tin telluride-based thermoelectric material comprises the following steps:

[0036] (1) Weigh tellurium, tin and aluminum in an argon environment and mix them uniformly to obtain mixed raw materials, then add them to a ball mill jar, and after vacuuming, feed the mixed gas, first ball mill for 2 hours at a speed of 140rpm, and then grind the balls and mix The mass ratio of raw materials is 1:20, and then ball milled at 450rpm for 17 hours to obtain mixed powder; the mixed gas is a mixture of hydrogen and argon at a volume ratio of 5:95; every 2 hours of ball milling, cooling for 15 minutes;

[0037] (2) Plasma sinter the mixed powder obtained in step (1) at 580° C. for 5 minutes, the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com